AGTEKS Orme ve Tekstil Endustrileri San. ve Tic. Ltd. Sti.

DirectCover-2S

Explore product

DirecTwist-2D6"

Explore product

Quality Bar

Explore product

DirecTwist-2C6"

Explore product

Shade Bar

Explore product

DirectCover-2S

Explore product

DirecTwist-2D6"

Explore product

Quality Bar

Explore product

DirecTwist-2C6"

Explore product

Shade Bar

Explore product

DirectCover-2S

Explore product

DirecTwist-2D6"

Explore product

Quality Bar

Explore product

DirecTwist-2C6"

Explore product

Shade Bar

Explore productAddress

AGTEKS Orme ve Tekstil Endustrileri San. ve Tic. Ltd. Sti.

BOSB, Bakircilar Sanayi Sitesi

Orkide Cad. No: 5/7-8, Beylikduzu 34520

Istanbul

Türkei

Telephone+90 212 501 22 26

Fax+90 212 612 70 98

Discover more from us

About us

AGTEKS was founded in 1992 as a textile machinery manufacturer in Istanbul. As manufacturers have required higher quality yarn for higher quality garments, AGTEKS has risen to the challenge of researching and developing solutions for economical and functional products for the yarn industry. In keeping with the research and development objective of highly qualified and experienced engineering staff, AGTEKS is one of the fastest developing companies in the world. Our team continually implements many new twisting and sensing solutions to service the textile industry while working with direct contacts in the market, universities, renowned experts and research institutes worldwide. Through the release and installation of these technologies, AGTEKS continues to produce the most innovative and versatile twisting and covering machines in the market. AGTEKS’ new line of industrial sensing solutions keeps with their solid reputation in introducing previously unavailable solutions and meeting market demands and requirements.

“Total quality” and “customer satisfaction in any case” are our strict mottos at AGTEKS. Our customer feedback proves that AGTEKS produces the highest quality products and provides elite after-sales service. AGTEKS provides quality service with many international patents, thousands of happy customers in more than 80 countries, and numerous reputable agents worldwide. Today, AGTEKS focuses on producing highly technical textile machines and online quality control systems from yarn to garment. AGTEKS is proud to serve the textile industry globally with their integral developments and top-quality products.

Our product groups

- Technology and Processes

Keywords

- twisting

- covering

- quality

- sensing

- control

Our Products

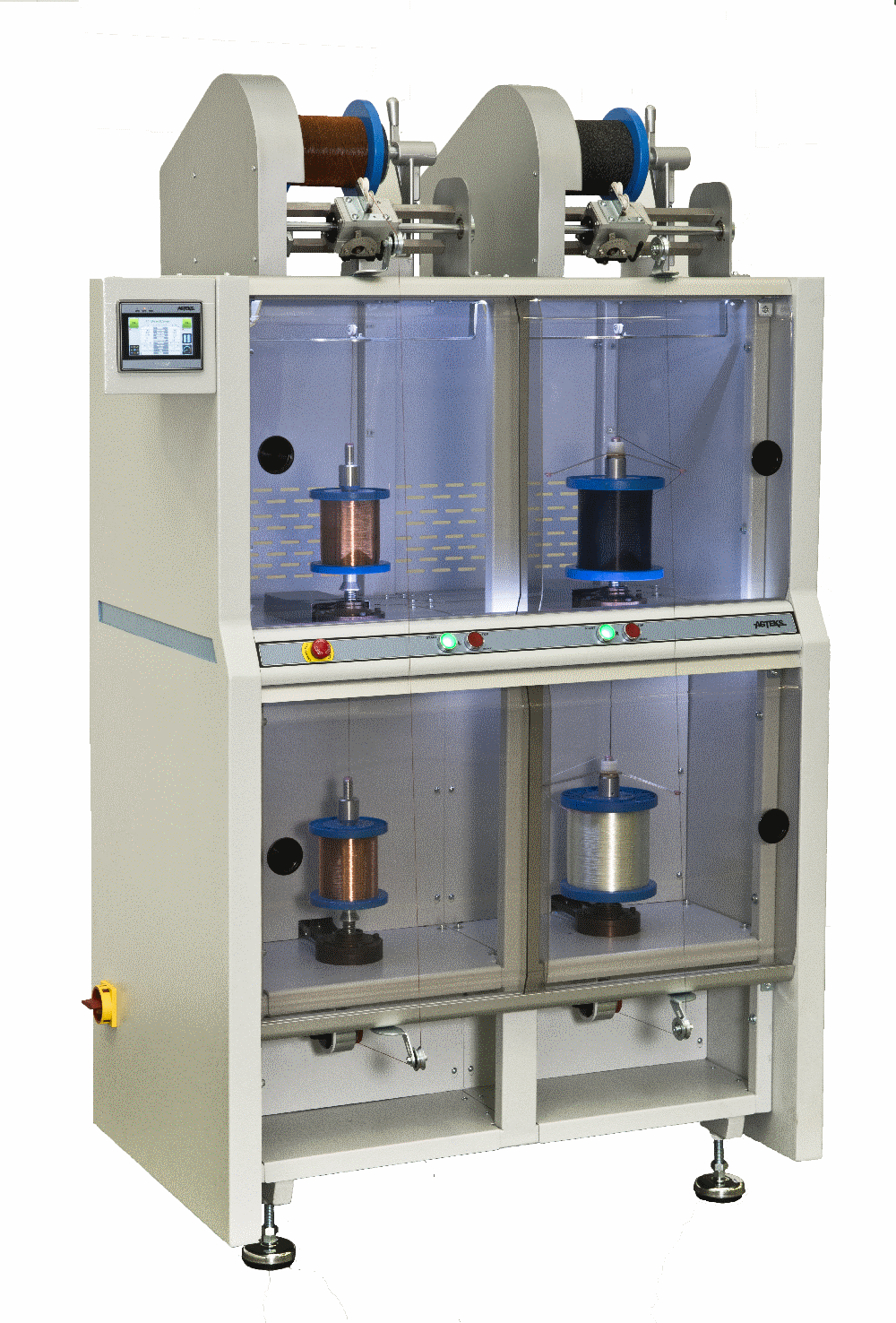

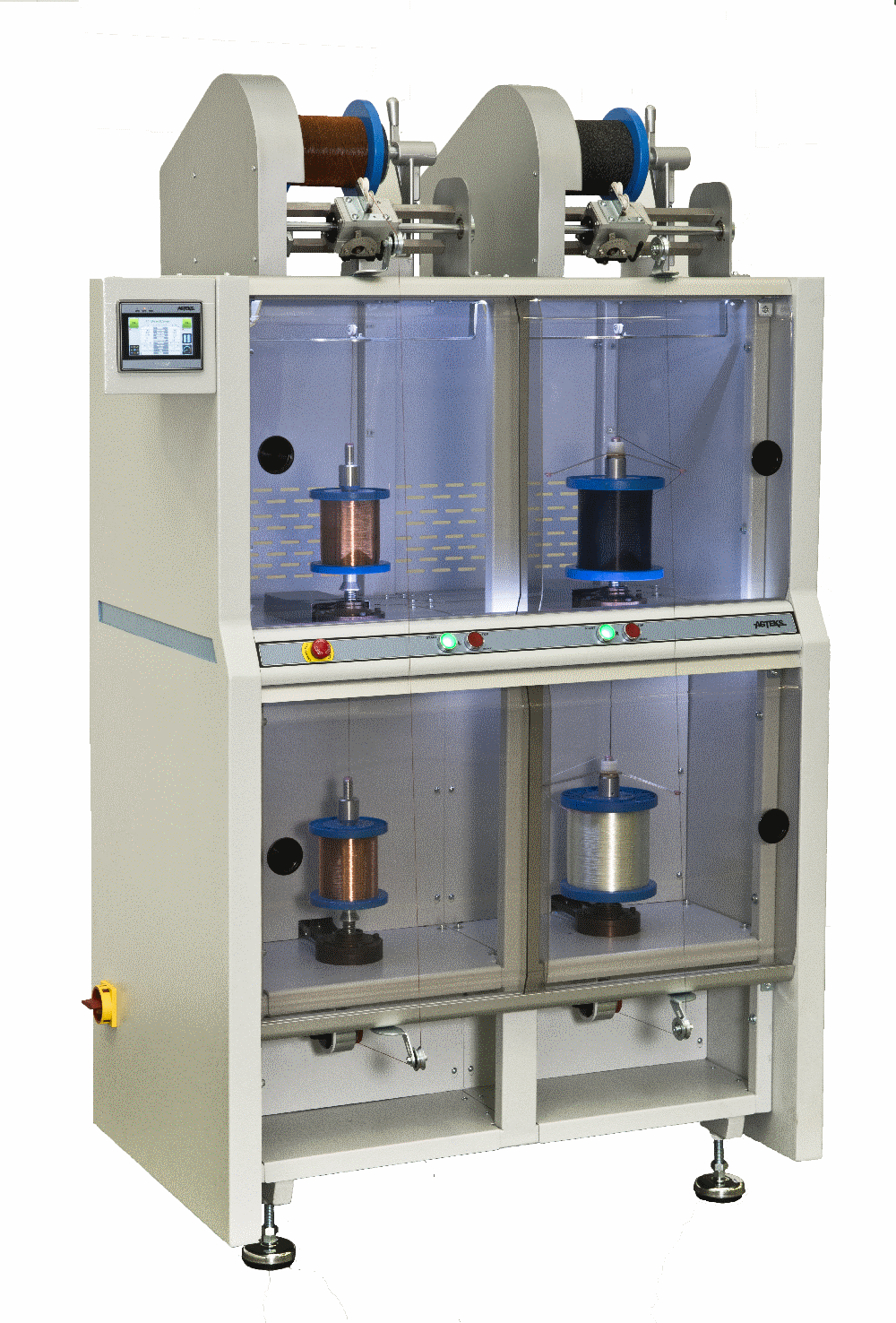

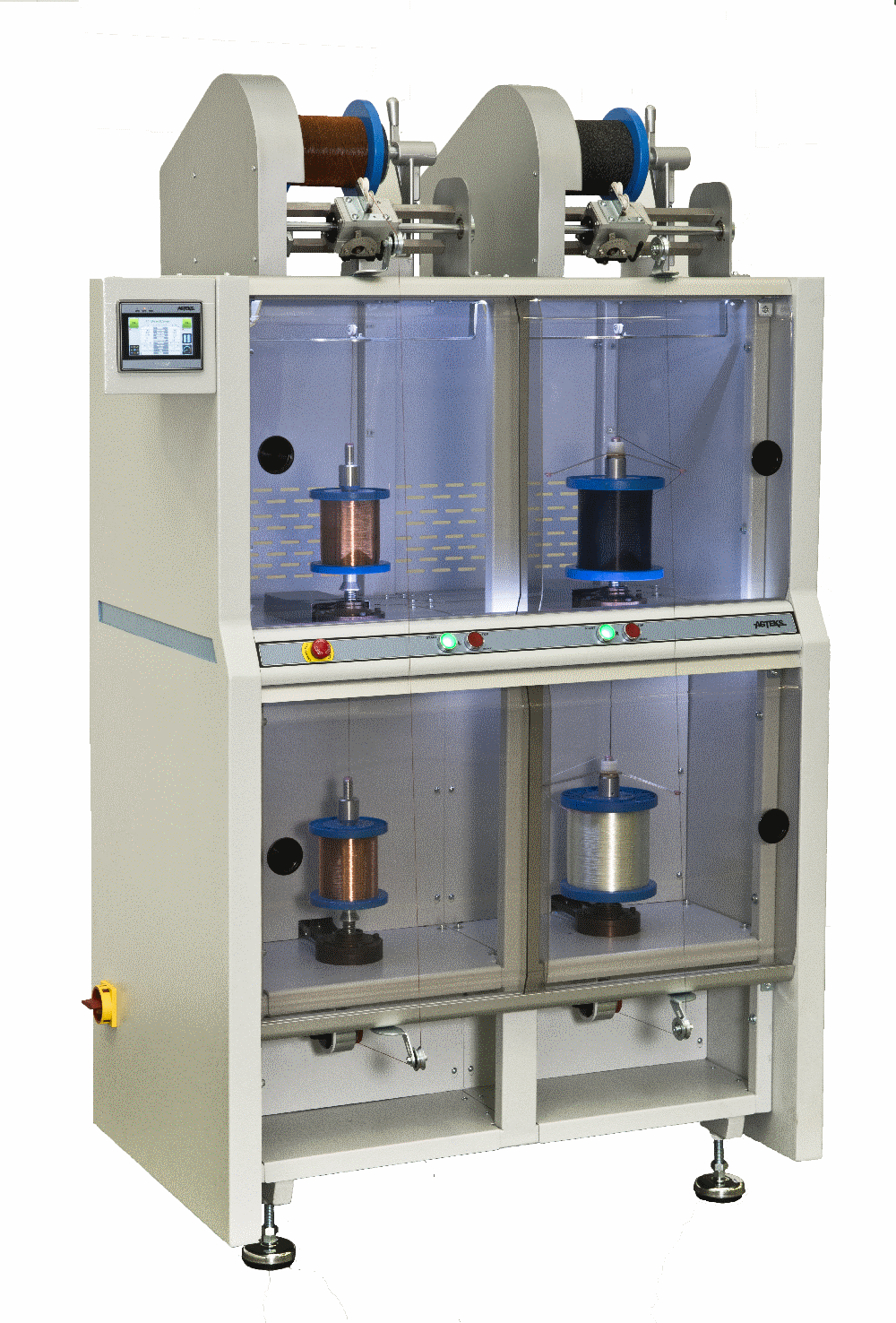

DirectCover-2S

It is the machine that can perform both S and Z covering processes in one operation at the same time. You can realize your dream covering operation with 100% covering for all kind of yarns.

DirecTwist-2D6"

You can perform twisting and covering processes with your technical yarns such as carbon, glass, metal, aramid and so on. It is also possible to use any type of yarn. Thanks to its high-tech design, you can produce your yarn from the first meter to the last meter. You can become the new star of the technical textile industry by meeting the world’s best twisting machine.

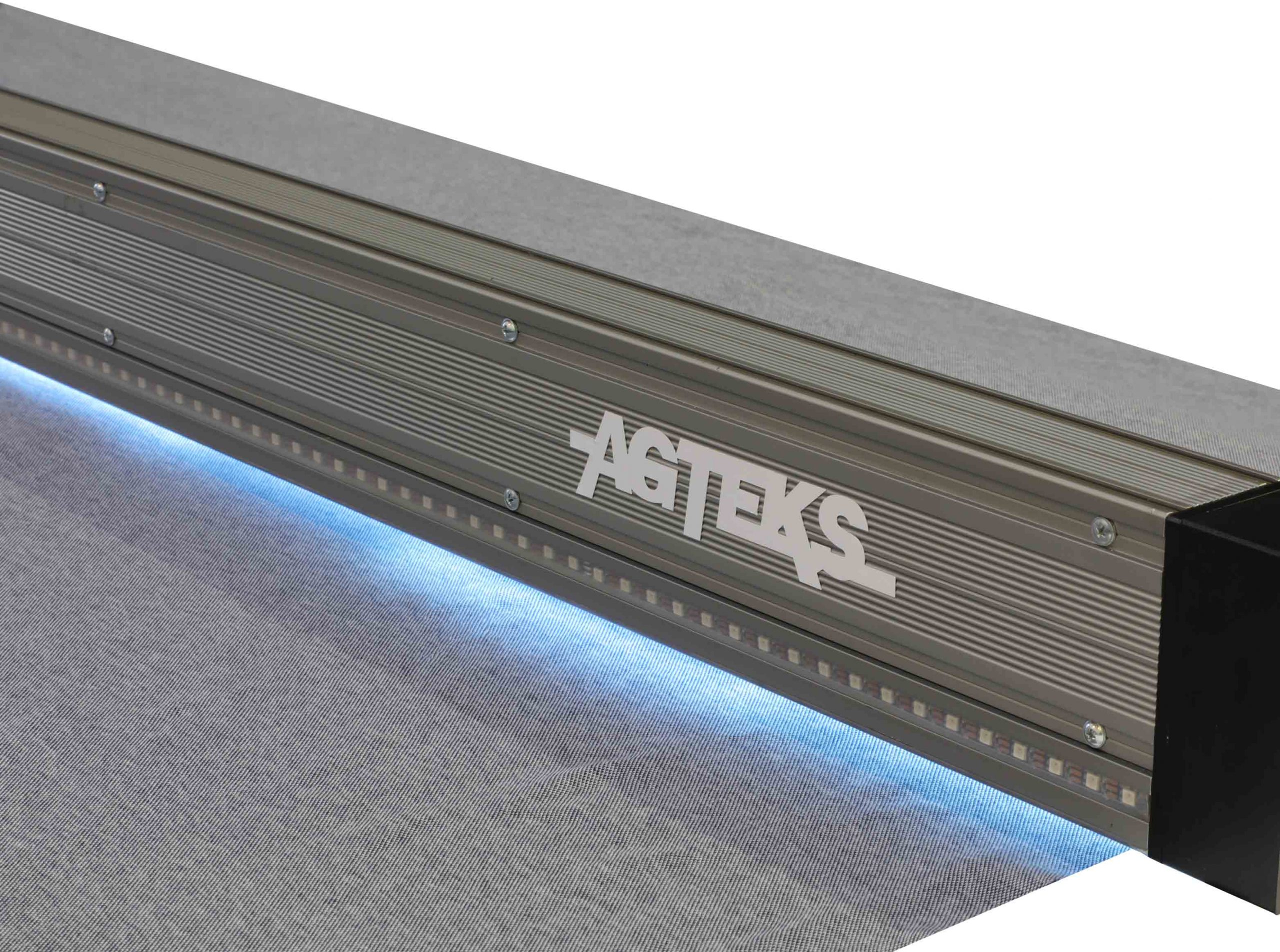

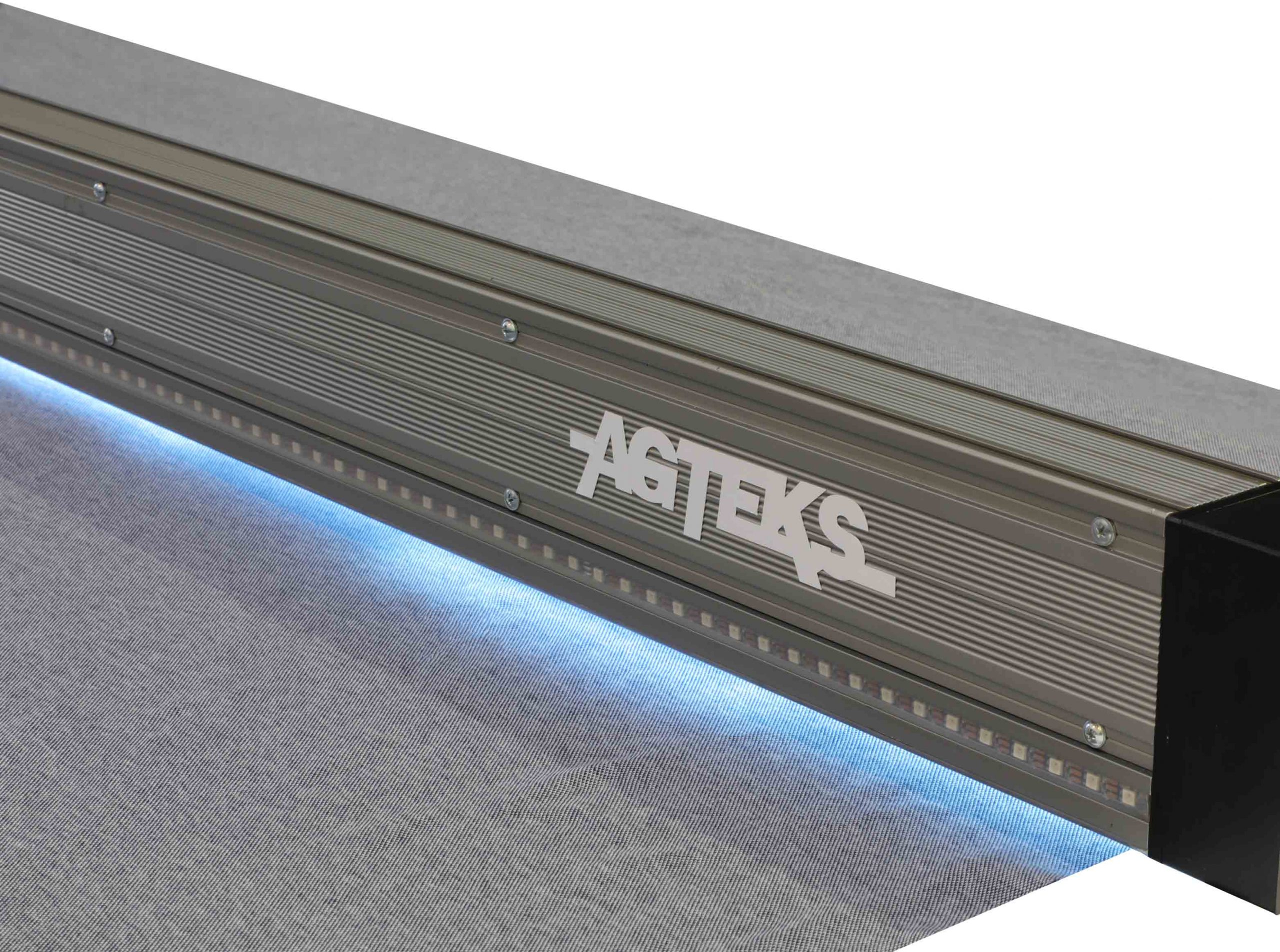

Quality Bar

Quality Bar simultaneously detects, names and reports visual defects on the fabric. Designed with artificial intelligence and deep learning algorithms, Quality Bar provides fabric quality control with a 95% accuracy rate by eliminating the human factor in a compact feature. Quality Bar, one of the pioneers of Industry 4.0 breakthrough in the textile sector, is an “intelligent” quality control system.

Quality Bar provides quality control with its multi-mode scanning system and light sources reflected on the fabric. It is a real high-resolution online fabric quality control system with simultaneous front and backlighting.

Quality Bar detects point, horizontal and vertical defects on the fabric. Classifies and reports with a user-friendly interface.

DirecTwist-2C6"

It’s time to meet the most inclusive and best-selling machine in the DirectTwist series. You can easily twist and cover your staple fiber and continuous filaments with the highest level of efficiency.

As a result of its compact design, it is possible to create the combinations of your dreams for production, sample and R&D purposes.

Shade Bar

Shade Bar is an online quality control system that detects wing differences, color filtering and lot differences that may occur in the production of dyed fabrics with a spectrophotometer.

Shade Bar calculates Delta E differences by measuring L, a, b values on the flowing fabric instantly. It provides benefits in terms of quality and time in subsequent production processes.

The Shade Bar provides continuous color controls by measuring the optical reflectance values of the fabric. If necessary, it can also send a “stop” command to the machine during detection. ShadeBar, another pioneer of Industry 4.0 breakthrough in the textile industry, can send the calculated data to computer memory, cloud environment or web provider.

ShadeBar makes color measurements in accordance with the recommendations and decisions of the International Commission on Lighting (CIE-Commission Internationale de l’Eclairagel).

Our Contact Persons

SERVET BALCI

Geschäftsleitung

Vorstandsvorsitz

erdem ergene

Konstruktion

Abteilungsleiter*in

NIL GIZEM YILMAZ

Vertrieb

Angestellte*r