The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

AB-Tec GmbH & Co. KG

AB-Tec GmbH & Co. KG

Baarstrasse 110

58636 Iserlohn

Germany

Telephone+49 2371 2195525

Fax+49 2371 2195527

About us

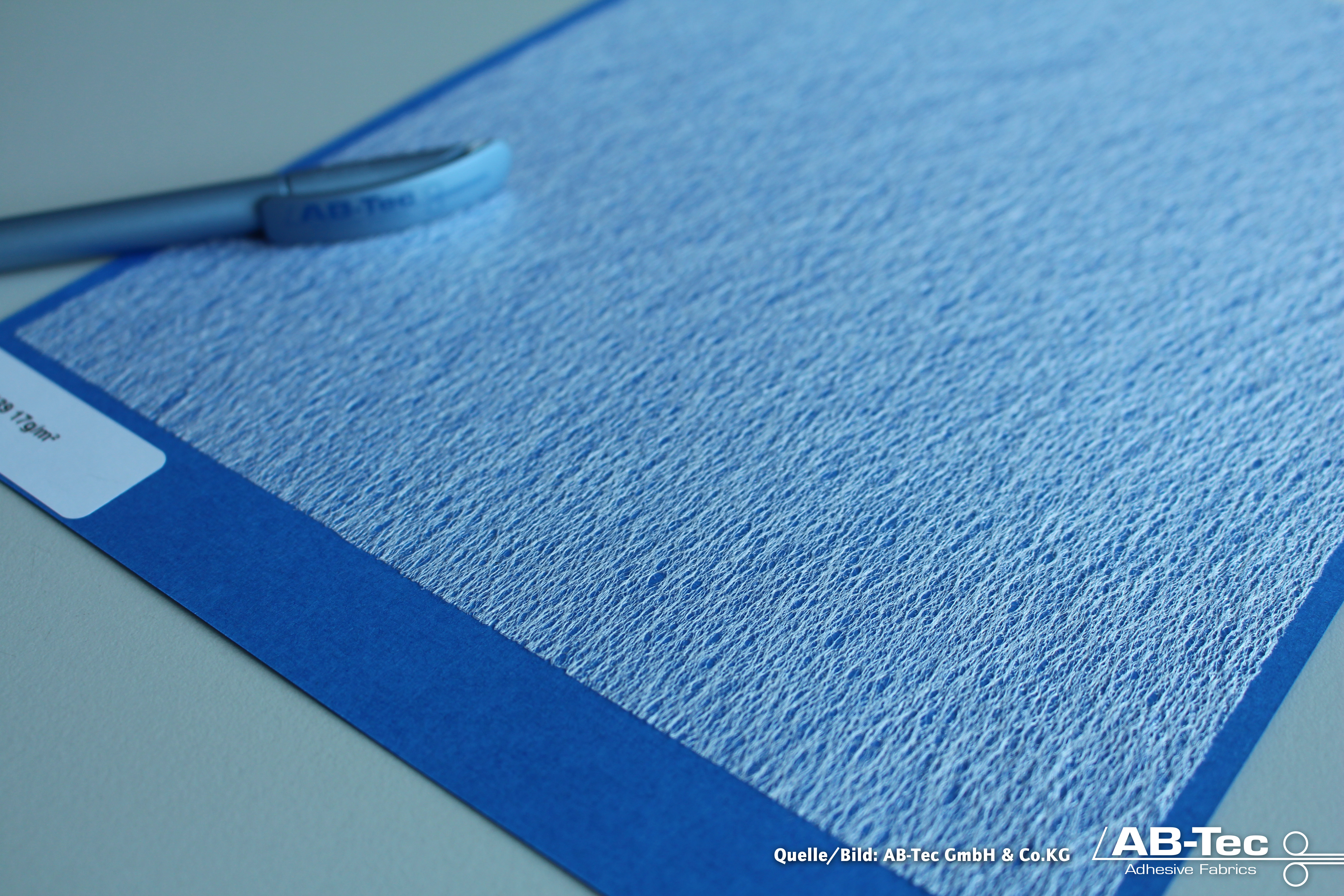

AB-Tec is a German manufacturer of roll-form thermoplastic web adhesives (Co-PA, Co-PES, Co-PO, Co-PP, Co-PU, Co-EVA and others), heat-activatable dry, breathable, flexible, solvent-free with limited penetration into porous or absorbent materials.

The exclusively locally in Iserlohn/Germany manufactured web adhesives are not like a film with a closed surface, but a porous three-dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of web adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

AB-Tec offers an extremely versatile pallet of clean High-Tech adhesives for continuous production and is specialised in providing solutions for demanding, individual customer tasks in the fields of stabilisation and laminating.

In doing so the company is not only able to call on many years of its own experience, but also the know-how of the world’s leading manufacturer, Spunfab Ltd., based in Ohio/USA.

Our product groups

- Bondtec (Surface & Bonding Techniques)

Our application areas / Solutions

Keywords

- Web

- Thermoplastischer Klebstoff

- Lamination

- thermoplastic adhesive web

- verbinden

Our Products

TecWeb®

As standard, the dry thermoplastic TecWeb® is delivered on a roll without foil or silicone paper. On customer request, delivery on a carrier is possible. TecWeb® adhesive is not a film with a closed surface, but a porous three-dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of TecWeb® adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

TecWeb® offers an extremely versatile pallet of High-Tech adhesives. This large flexibility results from different base polymers used to formulate the webs, e.g., co-polyamides, co-polyesters, co-polyolefins, co-polypropylenes, co-polyurethanes and co-EVA`s.

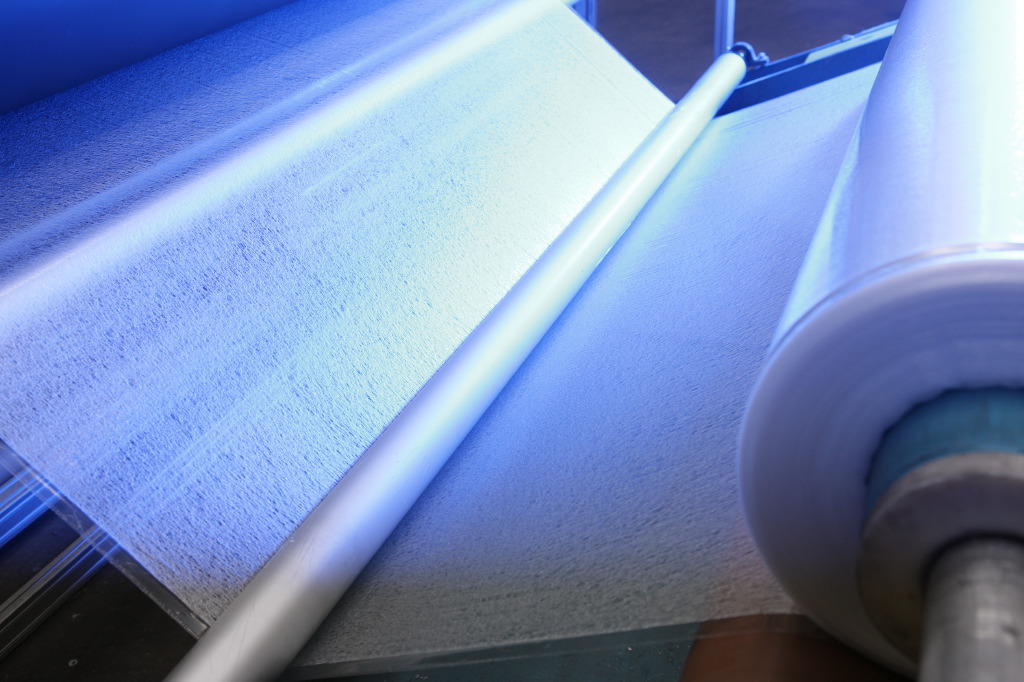

To process TecWeb®, three fundamental parameters are to be considered: temperature, pressure and time. To activate the thermoplastic web adhesive, a glue line temperature above the melting point is required. Pressure and time are then coordinated with the respective substrates, to ensure the highest quality laminate.

Why use TecWeb®?

Special Characteristics

- predictable performance and adhesion strength

- light weights

- open structure: does not trap air, steam- and air-permeable

- superb mechanical properties, excellent vacuum or thermoforming characteristics

- high resistance to chemicals such as lubricants, fuel and oils

- soft hand and high elasticity of flexibility

- limited penetration into porous or absorbent materials / substrates

- limited rustling noise (compared to a film or foil)

Production / Handling

- supplied in roll form

- continuous production

- easy to work with, high operating speed

- clean handling; no cleaning process necessary

- bonding of large material surfaces

- thermoplastic features

- rapid cooling

- processing and activation by flat-bed laminating, heat and pressure calendering or infra-red systems

- depending on the type of TecWeb®, steam activation and HF welding is possible

- resistance to coldness: unproblematic concerning transport and storage

Economical

- 100 % solids, no water

- environment-friendly: solvent-free and plasticizer-free

- edge to edge coverage

- precise adhesive weight on total surface

- consistent product quality, high reproducibility

- less waste (adaptable widths and weights)

TecWeb®

As standard, the dry thermoplastic TecWeb® is delivered on a roll without foil or silicone paper. On customer request, delivery on a carrier is possible. TecWeb® adhesive is not a film with a closed surface, but a porous three-dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of TecWeb® adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

TecWeb® offers an extremely versatile pallet of High-Tech adhesives. This large flexibility results from different base polymers used to formulate the webs, e.g., co-polyamides, co-polyesters, co-polyolefins, co-polypropylenes, co-polyurethanes and co-EVA`s.

To process TecWeb®, three fundamental parameters are to be considered: temperature, pressure and time. To activate the thermoplastic web adhesive, a glue line temperature above the melting point is required. Pressure and time are then coordinated with the respective substrates, to ensure the highest quality laminate.

Why use TecWeb®?

Special Characteristics

- predictable performance and adhesion strength

- light weights

- open structure: does not trap air, steam- and air-permeable

- superb mechanical properties, excellent vacuum or thermoforming characteristics

- high resistance to chemicals such as lubricants, fuel and oils

- soft hand and high elasticity of flexibility

- limited penetration into porous or absorbent materials / substrates

- limited rustling noise (compared to a film or foil)

Production / Handling

- supplied in roll form

- continuous production

- easy to work with, high operating speed

- clean handling; no cleaning process necessary

- bonding of large material surfaces

With TecWeb® laminated compound

As standard, the dry thermoplastic TecWeb® is delivered on a roll without foil or silicone paper. On customer request, delivery on a carrier is possible. TecWeb® adhesive is not a film with a closed surface, but a porous three-dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of TecWeb® adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

TecWeb® offers an extremely versatile pallet of High-Tech adhesives. This large flexibility results from different base polymers used to formulate the webs, e.g., co-polyamides, co-polyesters, co-polyolefins, co-polypropylenes, co-polyurethanes and co-EVA`s.

To process TecWeb®, three fundamental parameters are to be considered: temperature, pressure and time. To activate the thermoplastic web adhesive, a glue line temperature above the melting point is required. Pressure and time are then coordinated with the respective substrates, to ensure the highest quality laminate.

Why use TecWeb®?

Special Characteristics

- predictable performance and adhesion strength

- light weights

- open structure: does not trap air, steam- and air-permeable

- superb mechanical properties, excellent vacuum or thermoforming characteristics

- high resistance to chemicals such as lubricants, fuel and oils

- soft hand and high elasticity of flexibility

- limited penetration into porous or absorbent materials / substrates

- limited rustling noise (compared to a film or foil)

Production / Handling

- supplied in roll form

- continuous production

- easy to work with, high operating speed

- clean handling; no cleaning process necessary

- bonding of large material surfaces

Lamination with TecWeb®

As standard, the dry thermoplastic TecWeb® is delivered on a roll without foil or silicone paper. On customer request, delivery on a carrier is possible. TecWeb® adhesive is not a film with a closed surface, but a porous three-dimensional structure. The open structure makes the resultant laminate more flexible and breathable. Due to the structure of TecWeb® adhesives, other names such as veil, non-woven, nets or fleece adhesive are common.

TecWeb® offers an extremely versatile pallet of High-Tech adhesives. This large flexibility results from different base polymers used to formulate the webs, e.g., co-polyamides, co-polyesters, co-polyolefins, co-polypropylenes, co-polyurethanes and co-EVA`s.

To process TecWeb®, three fundamental parameters are to be considered: temperature, pressure and time. To activate the thermoplastic web adhesive, a glue line temperature above the melting point is required. Pressure and time are then coordinated with the respective substrates, to ensure the highest quality laminate.

Why use TecWeb®?

Special Characteristics

- predictable performance and adhesion strength

- light weights

- open structure: does not trap air, steam- and air-permeable

- superb mechanical properties, excellent vacuum or thermoforming characteristics

- high resistance to chemicals such as lubricants, fuel and oils

- soft hand and high elasticity of flexibility

- limited penetration into porous or absorbent materials / substrates

- limited rustling noise (compared to a film or foil)

Production / Handling

- supplied in roll form

- continuous production

- easy to work with, high operating speed

- clean handling; no cleaning process necessary

- bonding of large material surfaces

Our Contact Persons

Maria Aleixo

Sales

Head of Division

Bernhard Kaschner

General management

Managing Director