The exhibitors & products at Techtextil 2026 will be available here from mid-January 2026.

Axial Flow Fan B800CF with Carbon Fibre Blades

Axial Flow Fan B800CF with Carbon Fibre Blades

Description

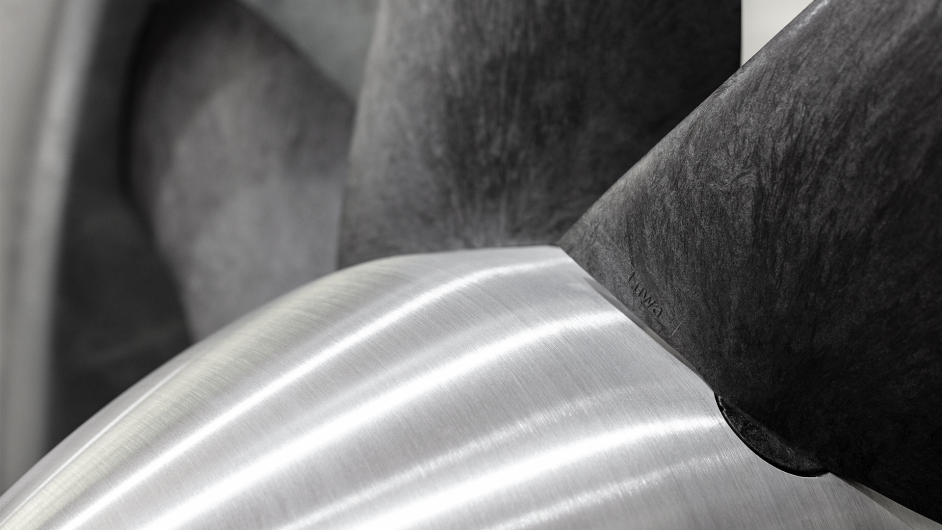

The fan blades of the new Axial Flow Fan B800CF are made of the very light and high-strength

“Hybrid Long-Carbon Fibre-Compound” (LCF) material. Compared to aluminum fans, LCF material allows new possibilities in design:

- larger blades,

- wider chord lengths at lower weight and

- lower mechanical stresses and thus

- more usable aerodynamic surface on the blade.

Benefits & Features

- Improved aerodynamics / efficiency

- Best performance and efficiency in typical P/V working ranges for industrial fans in textile air conditioning systems

- Designed for a wider operating range with consistently high energy efficiency

even under changing operating and pressure conditions

(e.g. condition and aging of filter media, changing number of running machines, etc.).

Increased performance

The impeller with its characteristic sickle-shaped blades is designed for optimal aerodynamic performance and most efficient operation. The use of high-quality materials and modern production methods allow for the unique shape of the blades – a factor that contributes signifficantly to the outstanding performance of the Axial Flow Fan with carbon fibre blades.

The benefits of the Luwa Axial Flow Fan series B800CF are reduced power consumption, higher fan performance, lower weight and reduced noise level.