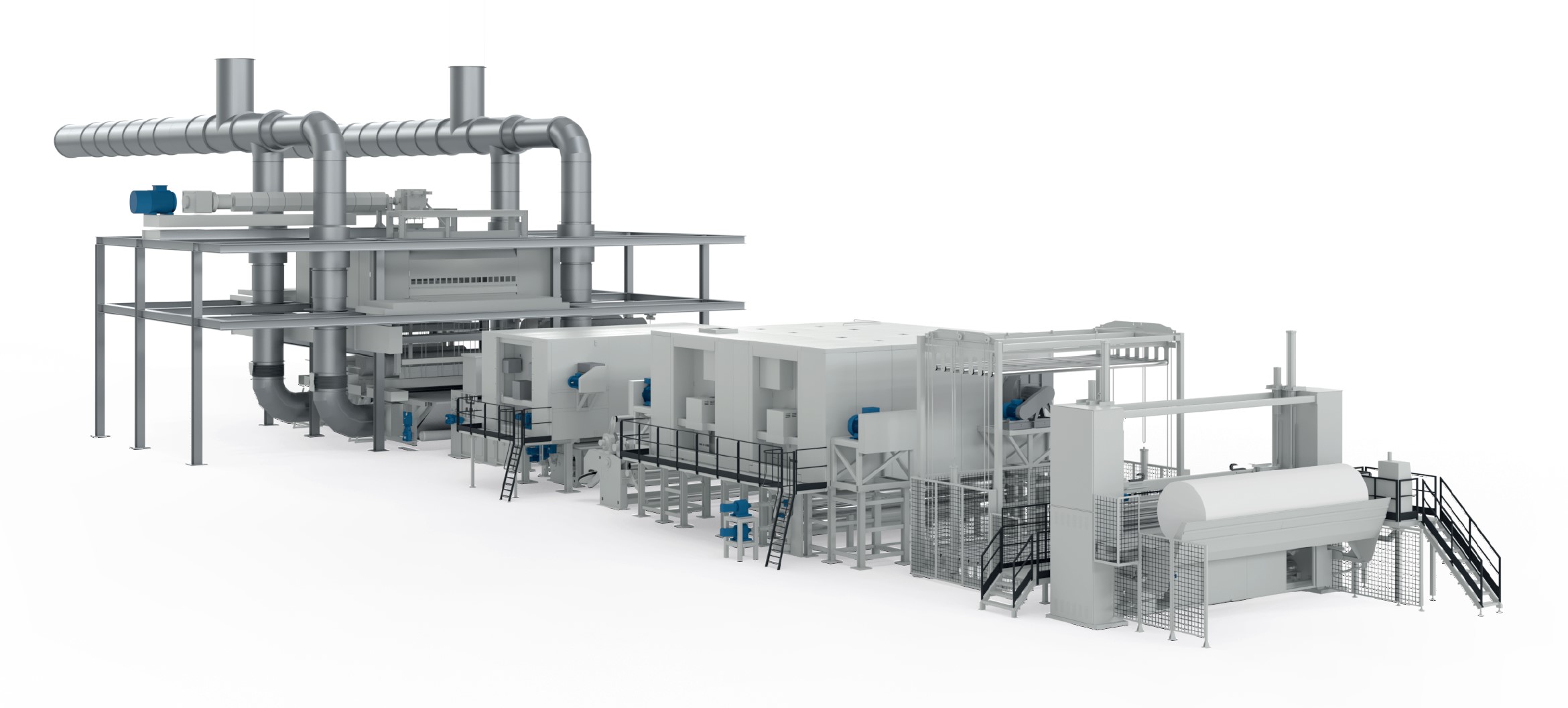

THERMOBONDING OVEN

Beschreibung

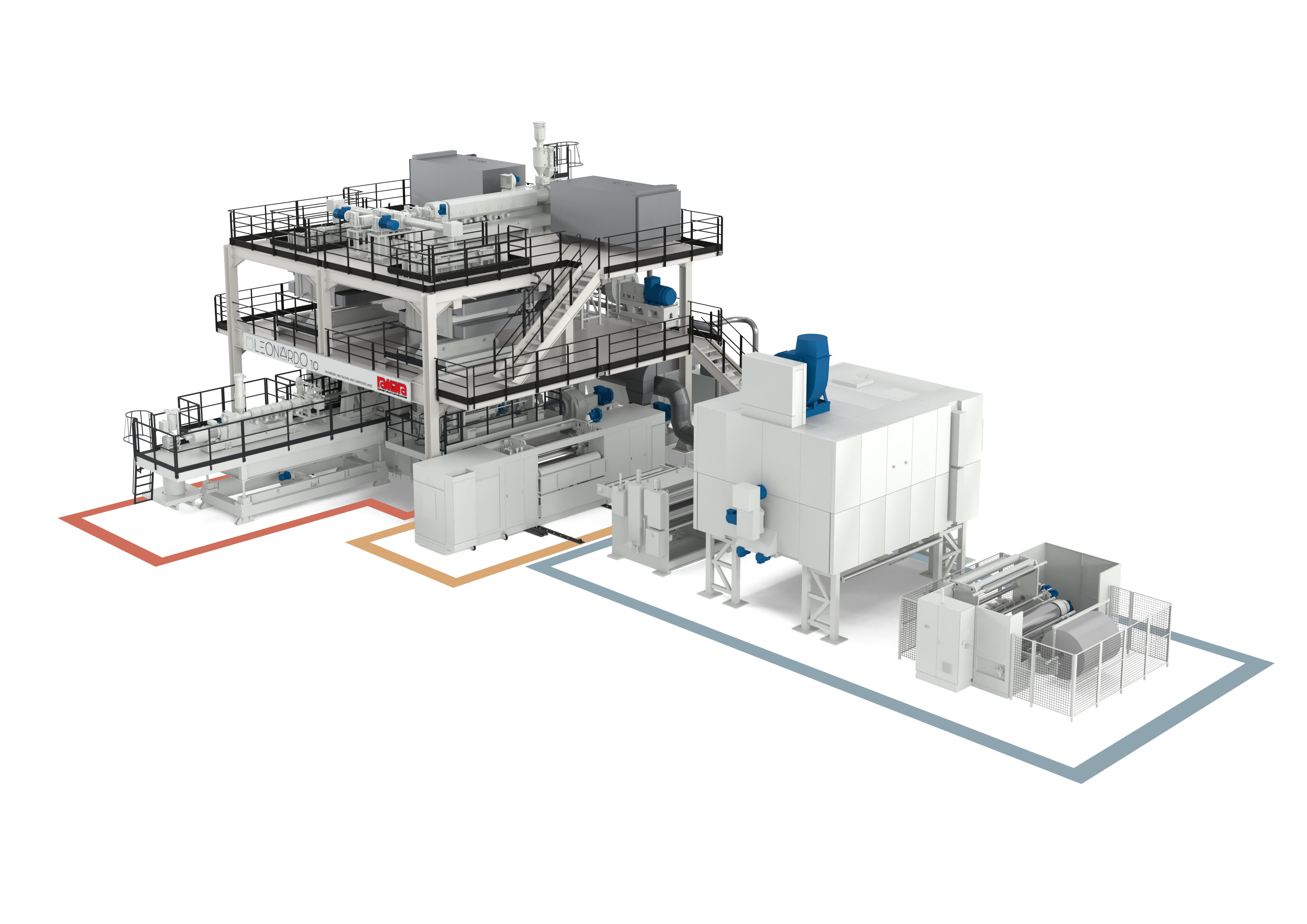

The tunnel oven is a key component for the treatment of nonwovens in thermobonding lines: in these lines the oven thermally fixes the fibers allowing realization of high-quality products with the desired thickness and weight (eg. wadding, insulating panels for building, air filters, etc.).

Air distribution takes place from top to bottom and vice versa, depending on the material to be thermobonded, in both the heating zones and in the cooling zones:especially in the production of wadding it is important that the air is addressed from the bottom to maintain its high-loft property.

The air is distributed in a perfectly uniform way thanks to the use of double perforated-sheet balance chambers, so that the air, heated by the burner and sent to the chamber by a fan, compresses with uniform pressure over the entire surface before exiting the perforated panel and going through the material under treatment.

Machine composition:

- Working width: up to 4200 mm

- Basic weight: 100 - 6000 g/m²

- Input product thickness: up to 1500 mm

- Output product thickness: 5 - 500 mm

- Output product density: 8 – 300 kg/m³

- Working temperature: 250°C

- PLC-controlled temperature, max. difference ± 1°C

- Working speed: up to 100 m/min

- Modular construction, 4,30 m long hot modules and 2,15 m long cold modules

- 120 mm rockwool insulation panels

- Air-inlet balance-chambers, guaranteeing a perfect air distribution

- Product ventilation can be automatically addressed from bottom to top and vice-versa

Type of heating:

- air-vein burners

- electrical exchangers

- steam exchangers

- thermal oil exchangers

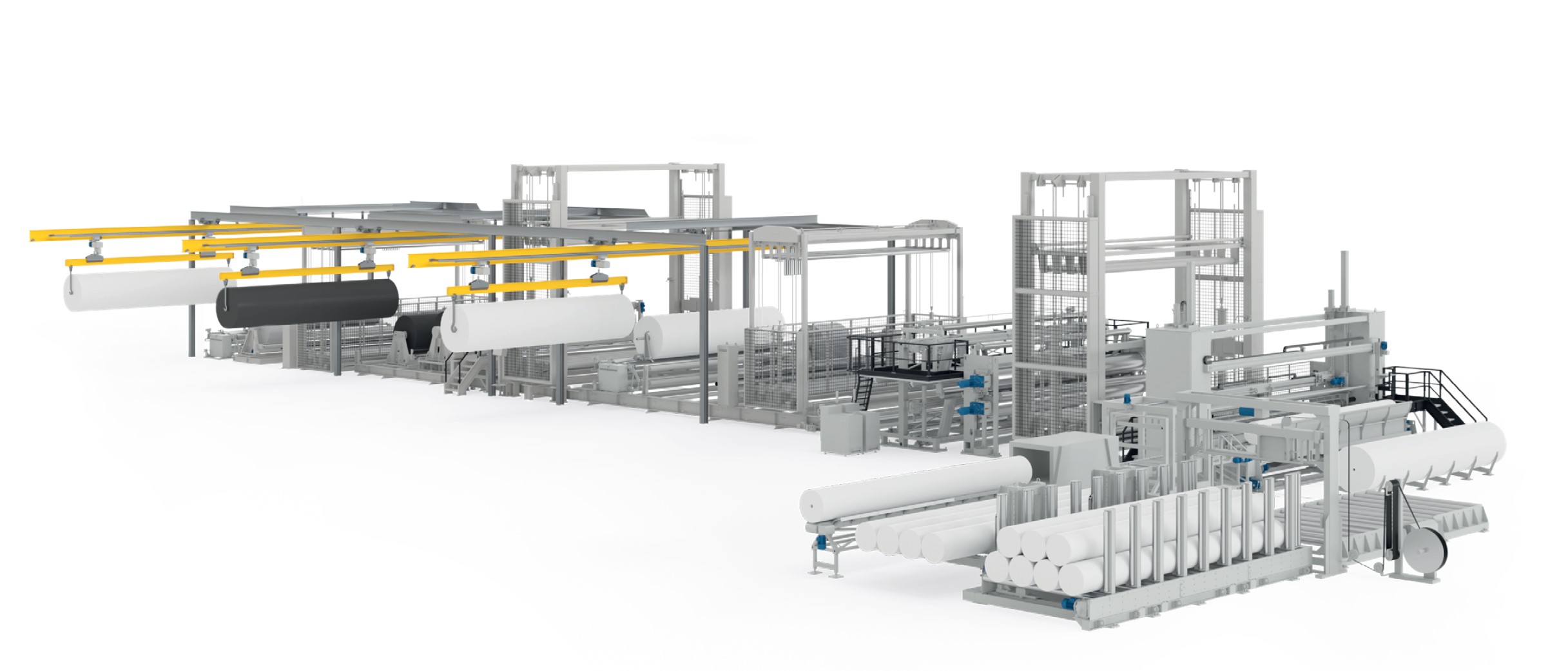

- Teflon upper and lower conveyor belts

- Air-suction width adjustment with Teflon shutters

- Belt-cleaning brushes

- Air-cooling with fans

- Suction exhauster

- Separation cylinder