Ramina S.r.l.

Ramina S.r.l.

Via Regina Elena 49

35010 Grantorto Padova

Italien

Telefon+39 049 596 0651

Fax+39 049 949 0250

Über uns

Ramina ist der führende, italienische Hersteller von Non-Woven Turn-Key Anlagen und Maschinen für Produktionslinien im Bereich von Spunbond PP und PET, Airlay, Thermobond, Vernadelung, Spun-Lay, Spray-Bond und Laminiertechnik.

Das Maschinenspektrum der eigenen Entwicklung, Konstruktion und Fertigung umfasst folgende Produktgruppen:

Tunnel- und Zylindertrockneranlagen, Kalander, Foulards, Pulverstreuaggregate, Oberflächenbehandlung, Längs- und Querschneidaggregate, pneumatische Speicheranlagen, Endwickler und Umwickelmaschinen, Verpackungssysteme, Faseröffnungs- und Fasermischanlagen, sowie Aggregate zur Vliesbildung der Air-Lay Technologie.

Unsere Produktgruppen

- Technology and Processes

- Produktionsverfahren

- Maschinen zur Flächenherstellung

Unsere Anwendungsbereiche / Lösungen

Keywords

- SPUNBOND LINE

- MELTBLOWN LINE

- COMPOSITES LINE

- LAMINATION LINE

- CALENDER

Unsere Produkte

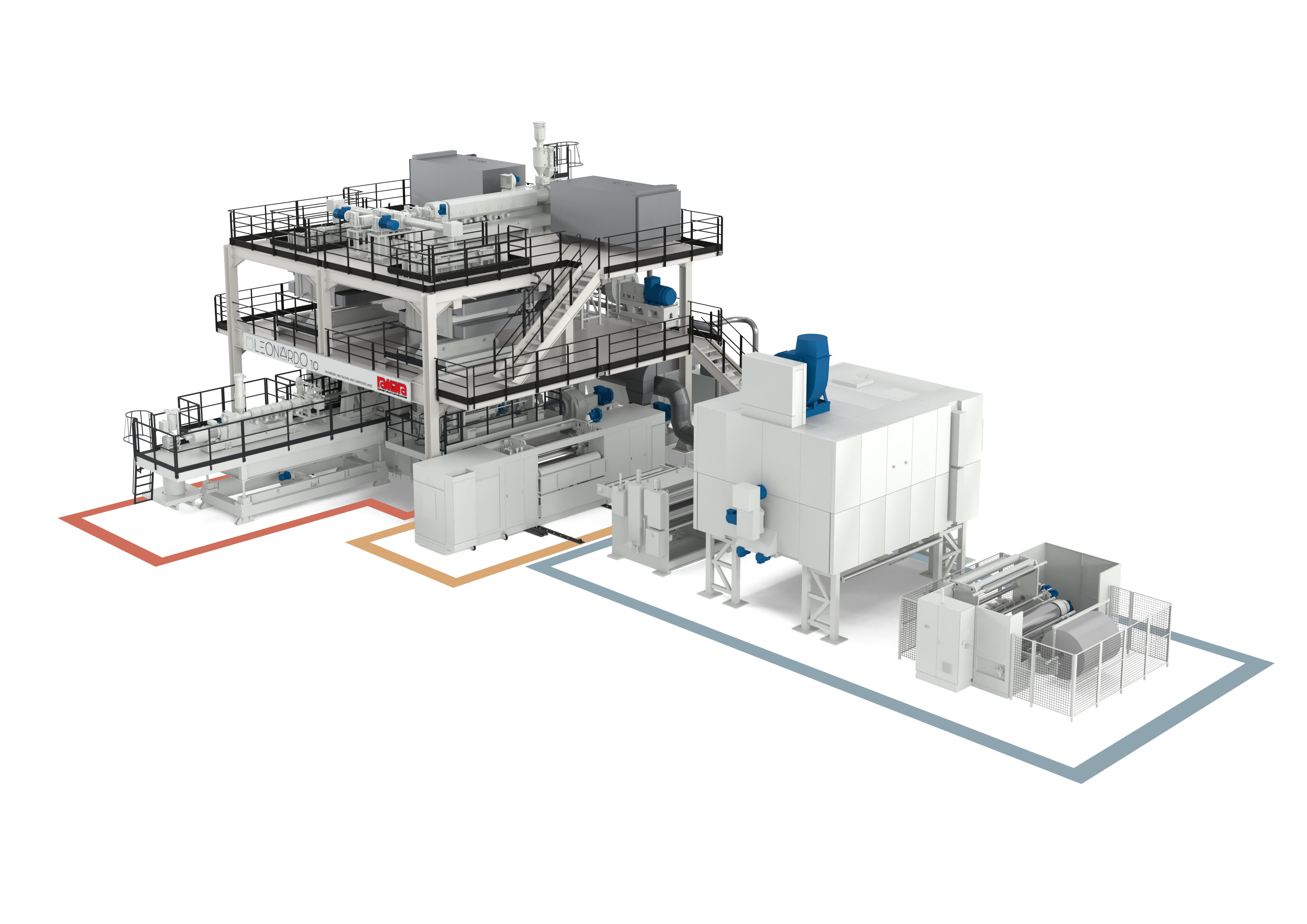

Leonardo 1.0 Spunbond, Meltblown and Composite lines

Leonardo 1.0 represents the innovation and the future in production by Ramina of Spunbond, meltblown and composite lines.

In a world where it is important to find a balance between production costs and high quality final products, Leonardo 1.0 offers the perfect solution. Flexible, reliable and cost-effective. It is possible to customize each line to suit different customers’ needs, producing high quality products at a fast pace, optimizing energy consumption.

Leonardo 1.0 lines help you create products for different industries.

Spunbonded fabrics are characterized by a high mechanical strength and resistance, which make them the optimal solution for the manufacturing of products for hygiene, medical, packaging and agriculture industries.

Meltblown fabrics reproduce the perfect barrier and filtration effect, and find their application in the production of sanitary products and absorbent coatings or filters.

Thanks to Leonardo 1.0 it is possible and easy to combine the two production technologies in a composite line to achieve countless nonwovens. These versatile fabrics are resistant and at the same time absorbent and filtering, perfect for the creation of medical products and work protection.

Leonardo 1.0 is efficient

Leonardo 1.0 technology allows a fast cleaning and maintenance process to reduce downtimes.

This is a big step forward and ensures a high level of productivity. Leonardo 1.0 saves customers’time and increases their revenues. The production ranges from 200 kg/h of spunbonded fabrics, to 50 kg/h for meltblown fabrics.

Leonardo 1.0 is green

Leonardo 1.0 technology allows to use Bio based polymer like PLA to produce biodagradable spunbond, meltblown and composites.

Ramina pays close attention to minimize the impact of its lines on the environment. For this reason the high productivity of Leonardo 1.0 goes hand-in-hand with energy saving technology.

Leonardo 1.0 is quick

The production speed reaches up to 1.000 m/min. A quicker production without compromising the quality.

Leonardo 1.0 is versatile

It opens an array of opportunities. Leonardo 1.0 gives you the technology to adapt your production according to the product you need to produce.

The line can be fitted with multiple technologies while guaranteeing a stable production process and uniform results.

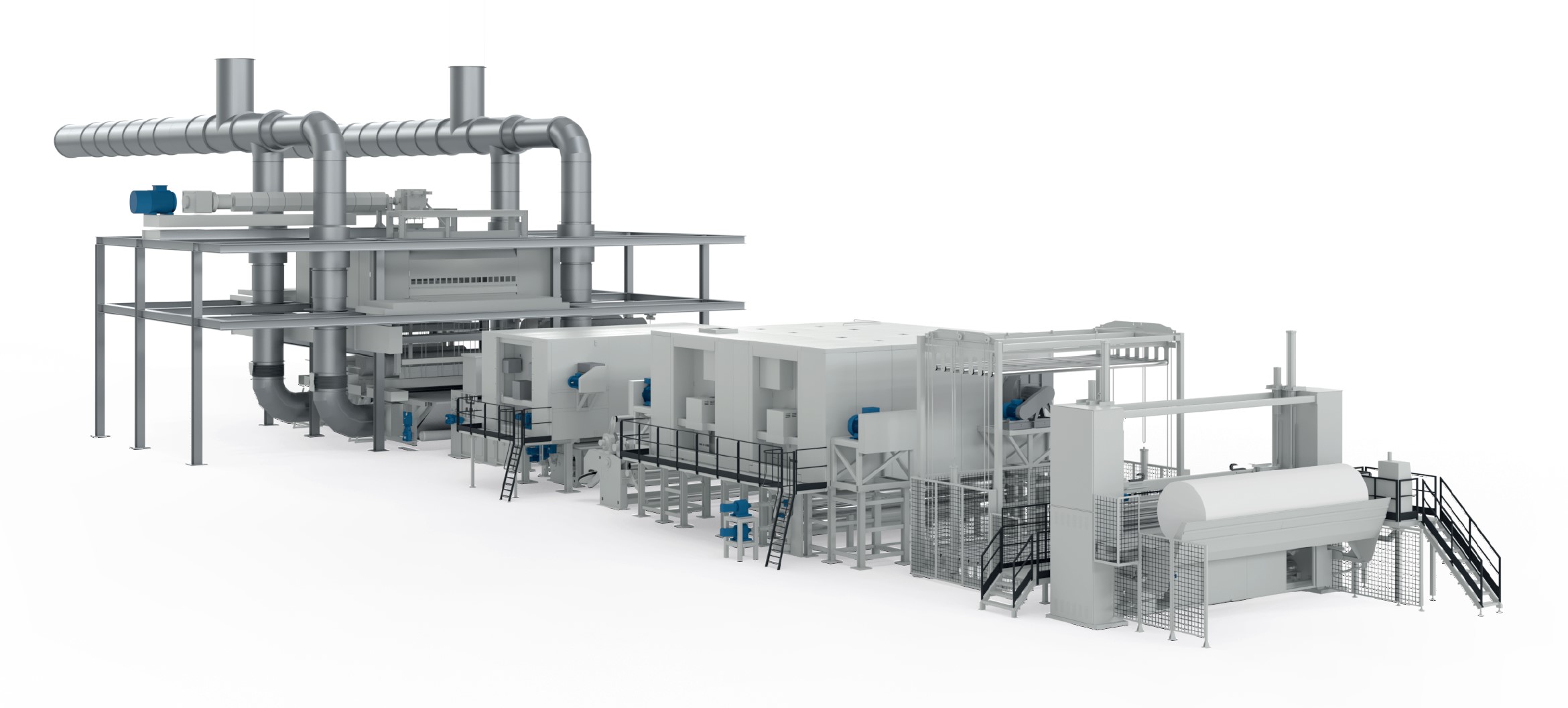

THERMOBONDING OVEN

The tunnel oven is a key component for the treatment of nonwovens in thermobonding lines: in these lines the oven thermally fixes the fibers allowing realization of high-quality products with the desired thickness and weight (eg. wadding, insulating panels for building, air filters, etc.).

Air distribution takes place from top to bottom and vice versa, depending on the material to be thermobonded, in both the heating zones and in the cooling zones:especially in the production of wadding it is important that the air is addressed from the bottom to maintain its high-loft property.

The air is distributed in a perfectly uniform way thanks to the use of double perforated-sheet balance chambers, so that the air, heated by the burner and sent to the chamber by a fan, compresses with uniform pressure over the entire surface before exiting the perforated panel and going through the material under treatment.

Machine composition:

- Working width: up to 4200 mm

- Basic weight: 100 - 6000 g/m²

- Input product thickness: up to 1500 mm

- Output product thickness: 5 - 500 mm

- Output product density: 8 – 300 kg/m³

- Working temperature: 250°C

- PLC-controlled temperature, max. difference ± 1°C

- Working speed: up to 100 m/min

- Modular construction, 4,30 m long hot modules and 2,15 m long cold modules

- 120 mm rockwool insulation panels

- Air-inlet balance-chambers, guaranteeing a perfect air distribution

- Product ventilation can be automatically addressed from bottom to top and vice-versa

Type of heating:

- air-vein burners

- electrical exchangers

- steam exchangers

- thermal oil exchangers

- Teflon upper and lower conveyor belts

- Air-suction width adjustment with Teflon shutters

- Belt-cleaning brushes

- Air-cooling with fans

- Suction exhauster

- Separation cylinder

CALENDER

Thanks to their high flexibility, Ramina’s hot calenders allow a large variety of applications in Nonwovens treatments; in particular, when applied to geotextile lines, they allow at the same time calibration and thermostabilization of the product, thanks to their 2 or 3 oil-heated cylinders.

Their particular engineering ensures the highest temperature & pressure uniformity: the best conditions for hi-tech and hi-quality nonwoven products.

Machine composition:

- Working width: up to 8.000 mm

- Working pressure: up to 100 N/mm

- Calibration accuracy: ± 0.15 mm

- Working temperature: max 250° C

- Heating system: gas boiler or electrical boiler

- Cylinders closing system: pneumatic or hydraulic

- 2 or 3 hot calibration cylinders

- Cross-axis system is used to compensate the deflection of cylinders and get a uniform product calibration: the upper cylinder skewing determines a variation of pressure on the center and is manually or PLC adjustable.

- Compact design

- Possibility to work online (speed determined by the line) or offline (speed set by operator)

- Short installation times due to machine pre-assembly at Ramina

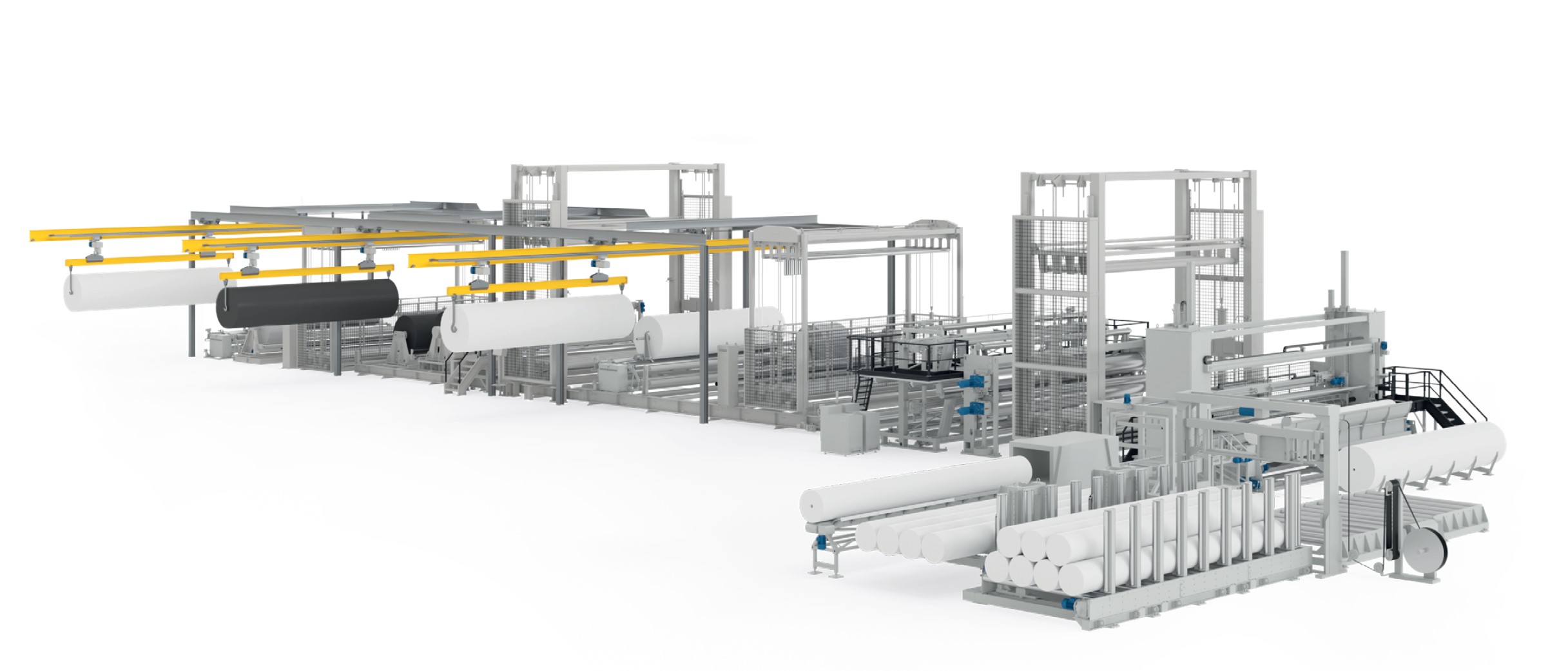

Spunbond roofing and geotextile line

Ramina designs and manufactures complete Spunbond Roofing and Geotextile lines starting from 100% PET polymer or flakes from recycled bottles. The line is used for the production of needle-punched fabrics for geotextile (50-700 gsm) and impregnated fabrics for roofing (80- 350 gsm). The first fabrics are used in road, railway, airport, landfill constructions and civil engineering works. The second nonwovens are used for roof coverings, underflooring, plumbing, and supports for roofing bituminous membranes.

The Spunbond Roofing line by Ramina uses an innovative technology that allows a lower energy consumption resulting in cost saving. In addition, the line is specifically designed to guarantee an easy accessibility for cleaning, extending line uptimes.

With the Spunbond Roofing line by Ramina it is possible to add fiberglass wires in the impregnated fabric for roofing reaching a higher tensile strength and longitudinal resistance.

LAMINATION LINE

Ramina designs and manufactures Lamination lines for Composites and Geocomposites.Thanks to its technology it is possible to laminate

up to three layers of many type of nonwovens with PE films, PVC, Geomembrane, Geogrid, Geomat, Geonet, HDPE, LDPE, Clay and other materials. The line can be adapted to laminate other auxiliary materials in order to meet customers’ needs and create a personalized product.