Leonardo 1.0 Spunbond, Meltblown and Composite lines

Leonardo 1.0 Spunbond, Meltblown and Composite lines

Beschreibung

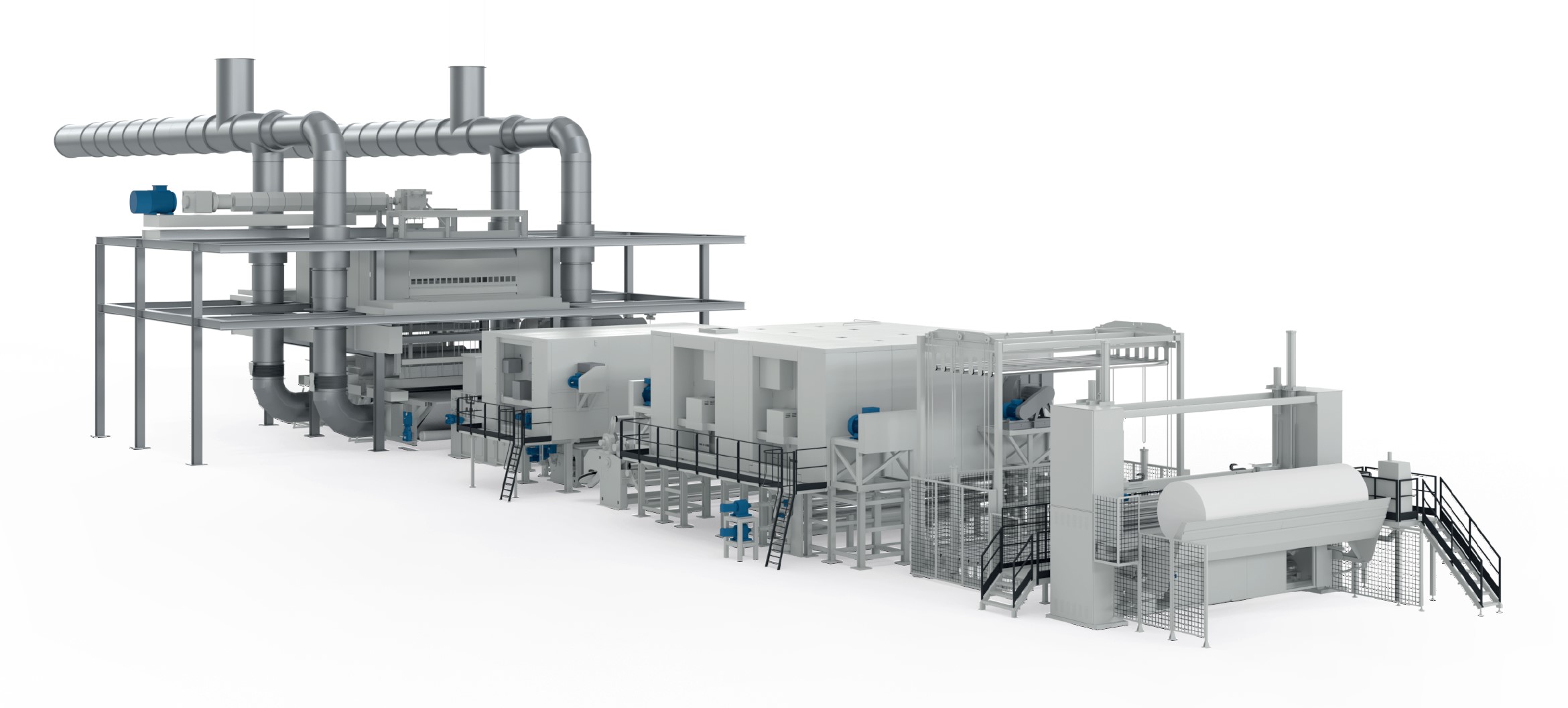

Leonardo 1.0 represents the innovation and the future in production by Ramina of Spunbond, meltblown and composite lines.

In a world where it is important to find a balance between production costs and high quality final products, Leonardo 1.0 offers the perfect solution. Flexible, reliable and cost-effective. It is possible to customize each line to suit different customers’ needs, producing high quality products at a fast pace, optimizing energy consumption.

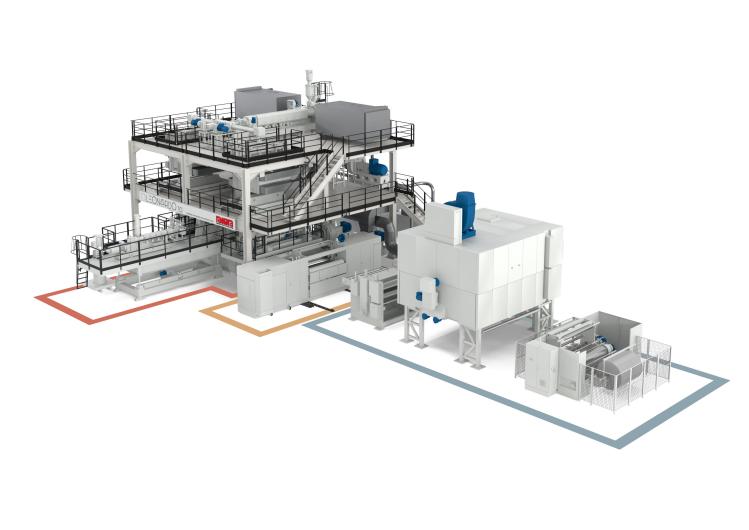

Leonardo 1.0 lines help you create products for different industries.

Spunbonded fabrics are characterized by a high mechanical strength and resistance, which make them the optimal solution for the manufacturing of products for hygiene, medical, packaging and agriculture industries.

Meltblown fabrics reproduce the perfect barrier and filtration effect, and find their application in the production of sanitary products and absorbent coatings or filters.

Thanks to Leonardo 1.0 it is possible and easy to combine the two production technologies in a composite line to achieve countless nonwovens. These versatile fabrics are resistant and at the same time absorbent and filtering, perfect for the creation of medical products and work protection.

Leonardo 1.0 is efficient

Leonardo 1.0 technology allows a fast cleaning and maintenance process to reduce downtimes.

This is a big step forward and ensures a high level of productivity. Leonardo 1.0 saves customers’time and increases their revenues. The production ranges from 200 kg/h of spunbonded fabrics, to 50 kg/h for meltblown fabrics.

Leonardo 1.0 is green

Leonardo 1.0 technology allows to use Bio based polymer like PLA to produce biodagradable spunbond, meltblown and composites.

Ramina pays close attention to minimize the impact of its lines on the environment. For this reason the high productivity of Leonardo 1.0 goes hand-in-hand with energy saving technology.

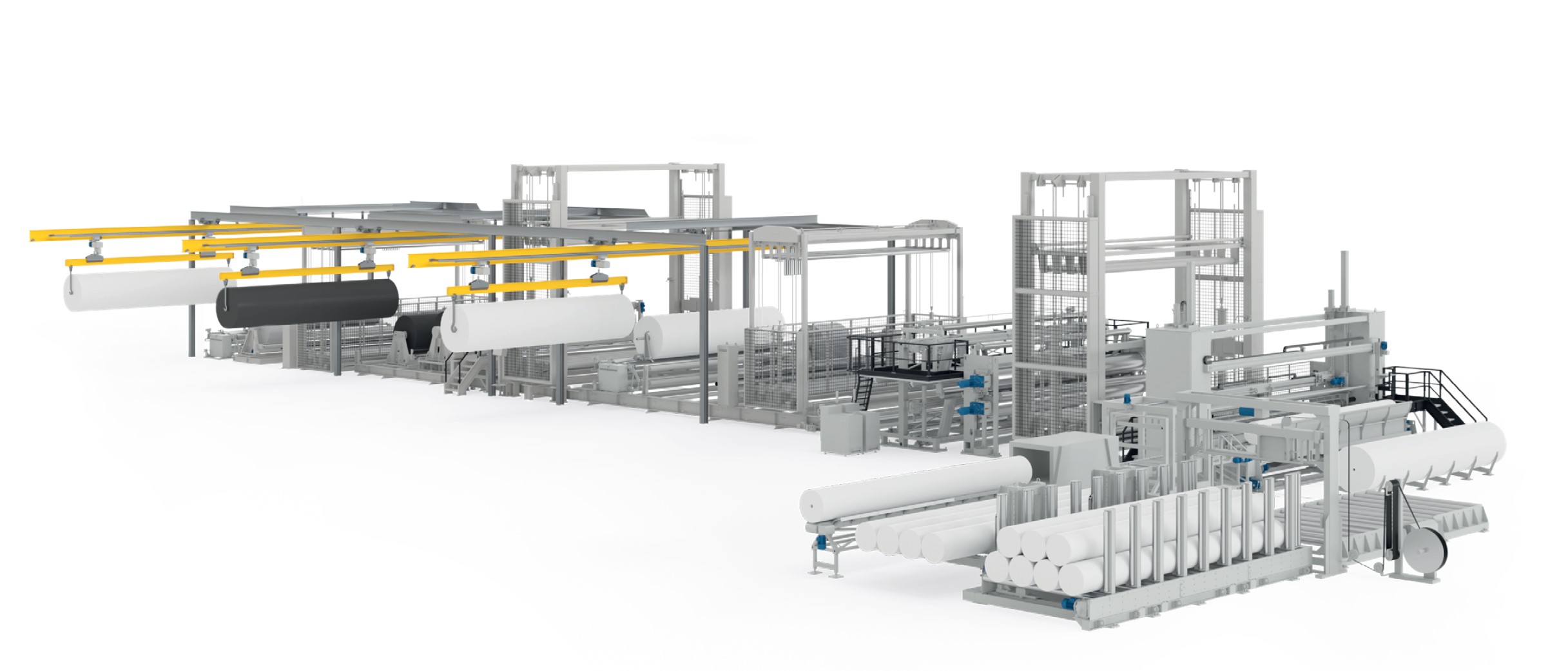

Leonardo 1.0 is quick

The production speed reaches up to 1.000 m/min. A quicker production without compromising the quality.

Leonardo 1.0 is versatile

It opens an array of opportunities. Leonardo 1.0 gives you the technology to adapt your production according to the product you need to produce.

The line can be fitted with multiple technologies while guaranteeing a stable production process and uniform results.