Aqua Kulturen

Beschreibung

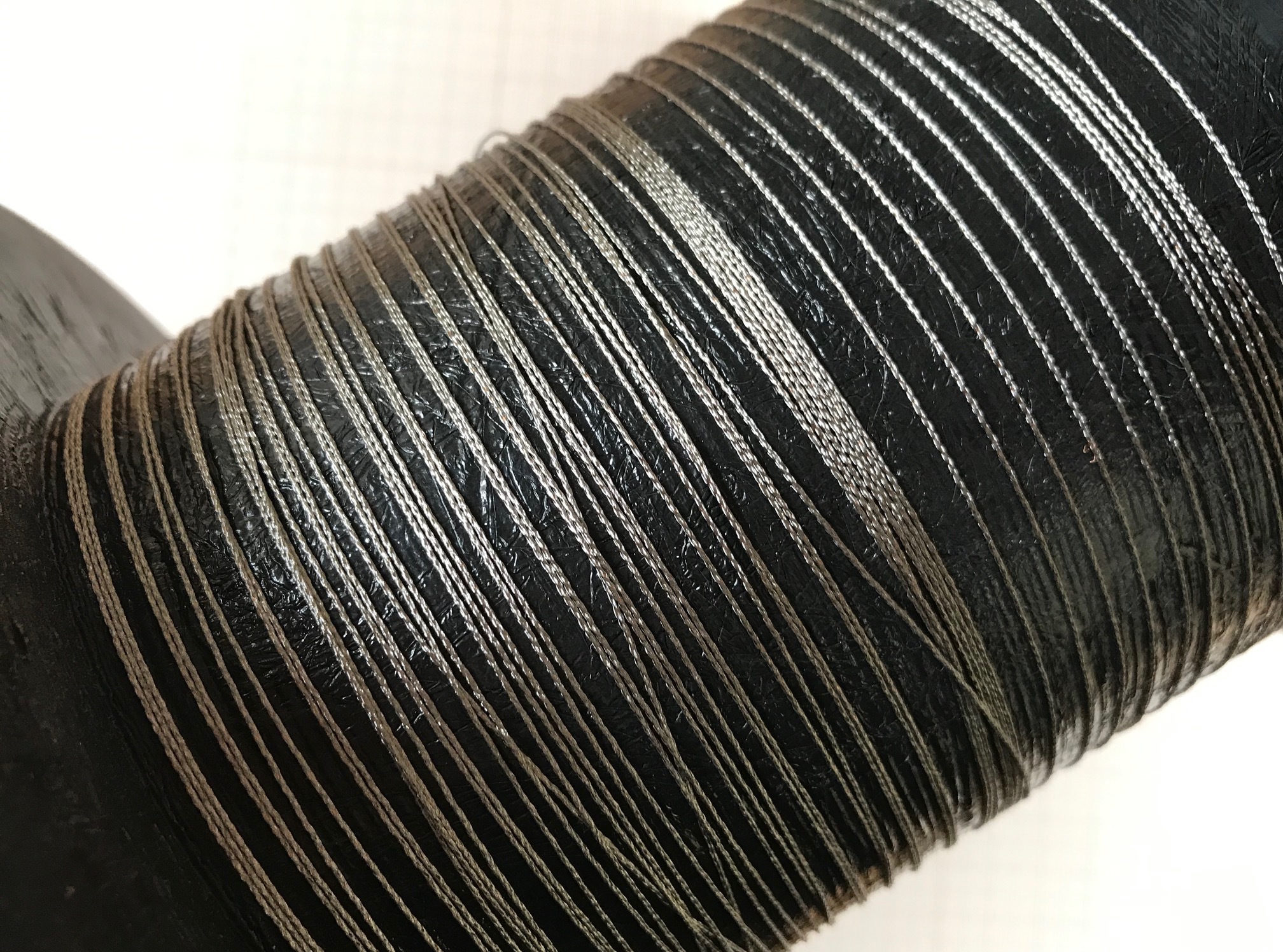

Since the 1960s, Filt1860 develop it’s know how in the field of aquaculture,in France, more specifically in the field of mussel farming. We provide mussel growers with nets that meet their needs and also meet environmental criteria.

- Catinage net, in high tenacity polyester, UV treated.

- Boudinage nets, Mytidouble: mixed synthetic and cotton, several possible densities.

- Net for seed rope, in polyester, polypropylene or cotton.

- Polyester/rubber or cotton/rubber elastic net.

- Net for mussel farming on stake sea.

- Net for mussel farming on ropes.

The nets are packaged in reels sold by the meter. On request, we prepare ready-to-use nets: cut to measure, tied, and/or elasticated.

Our know-how allows us to work on a specific material or on two different materials.

The cotton maintains the mussel seed during the laying of the net by releasing the space necessary for the mussels. The polypropylene guarantees the hold of the mussels during winding on the stake and handling.

We manufacture boudinage nets, for the cultivation of mussels on stakes and on ropes, with meshes of 14 to 40mm per side.

Catinage nets keep the mussels on the stake as they grow. They protect the mussels from the swell, the flow but also from marine predators.

We can work these nets in synthetic material such as polypropylene or polyester.

We manufacture catinage nets, with meshes from 20 to 60mm per side.