Die Aussteller & Produkte der Techtextil 2026 finden Sie ab Mitte Januar 2026 hier.

Über uns

Die Firma EM-Systeme GmbH wurde im Jahr 1999 gegründet und beschäftigt sich mit dem Ultraschallschneiden und -schweißen sowie Werkzeug- und Vorrichtungsbau.

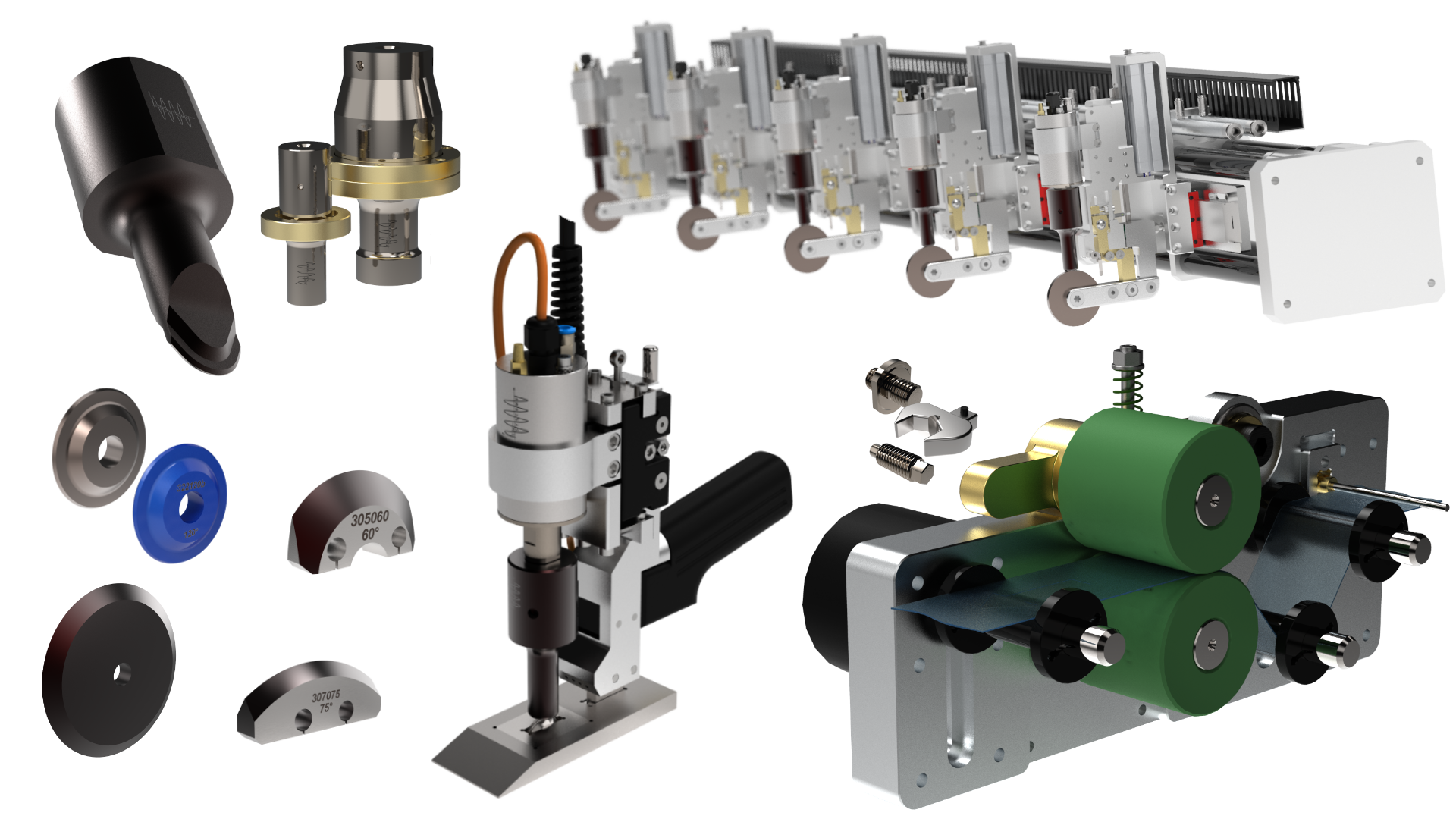

Die Produkte sind Trennschweißsysteme für thermoplastische Gewebe, Ultraschallsysteme zum Schneiden hochfester Fasern, Sonotroden, Vollhartmetallmesser, Ultraschallschweißkomponenten. sowie anwendungsspezifisches Zubehör.

Unsere Kunden sind sowohl Maschinenbauer, als auch Endanwender die Lösungen für die Integration in vorhandene oder geplante Anlagen suchen. Hier zahlt sich unsere langjährige Erfahrung als Hersteller der Komponenten aus, indem wir nicht nur die Kernkomponenten liefern, sondern auch Erfahrung in der Einbindung in Fertigungsmaschinen einbringen.

Wir bilden an unserem Standort in Oberhausen von der Anwendungstechnik über Entwicklung, Konstruktion, Fertigung und Montage ab.

Nutzen Sie unsere Erfahrung.

Unsere Produktgruppen

- Technology and Processes

- Produktionsverfahren

- Technisches Zubehör

Unsere Anwendungsbereiche / Lösungen

Mehr über uns

Ultraschallschneiden hochfester Fasern

Downloads

Keywords

- Ultraschall / Ultrasonic

- Schneiden / Cut

- Schweißen / Seal

- Sonotroden / Sonotrodes

- Messer / Knife tip

Unsere Produkte

Ultraschallschneiden

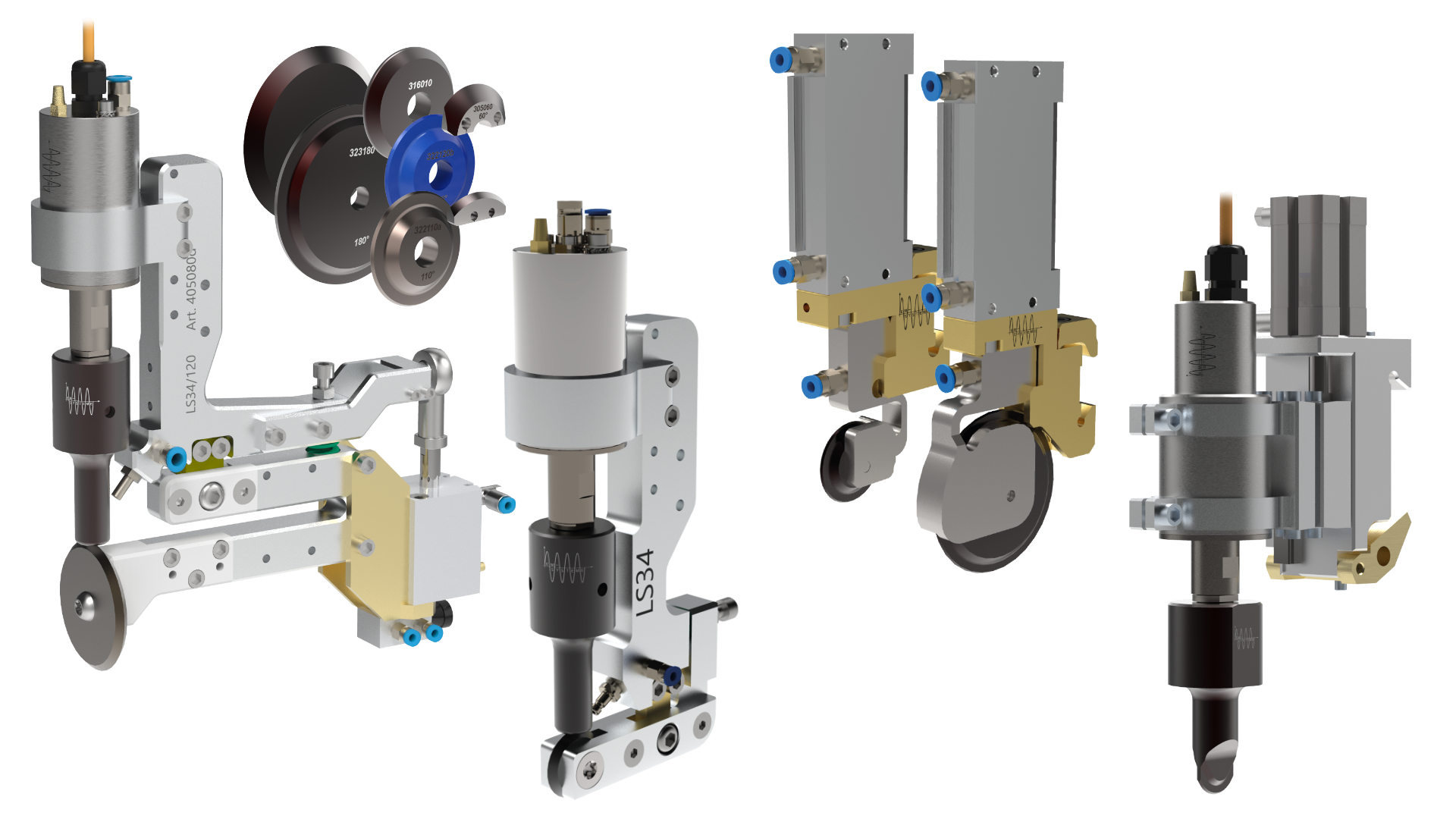

Dieser Begriff steht meist stellvertretend für das Trennschweißen, auch als „Cut and Seal“ bezeichnet, von thermoplastischen Textilien. Hierbei wird das zu schneidende Material zwischen einer Sonotrode und Amboss durchgezogen. In der Regel ist eines der beiden Werkzeug plan und das Gegenstück mit einer eher stumpfen Schneide versehen. Durch die Ultraschalleinwirkung plastifizert das Material und wird gleichzeitzig abgequetcht und versiegelt. Eine Vielzahl an Standardprodukten sowie entsprechendem Zubehör, welches wir durch unsere jahrelange Erfahrung entwickelt haben, ermöglichen eine einfache Integration in Neu- oder vorhandene Produktionsmaschinen.

Mehr unter: https://www.em-systeme.de/ultraschallschneiden/trennschweisssysteme-kontinuierliche-applikation/

Schweißpressen

Elektrische, pneumatische oder auch manuell betriebene Pressen sind häufig die Basis für einen reproduzierbaren Produktionsprozess. Unsere Schweißpressen werden je nach Anwendung aus unserem Portfolio ausgewählt und können anwendungsspezifisch modifiziert werden.

Die Typenvielfalt reicht von Mikropresse mit einer Schließkraft ca 10N bis zur Ultraschallstanze mit deutlich über 10.000N.

Mehr unter:

https://www.em-systeme.de/ultraschallschweissen/komponenten-fuer-den-maschinenbau/

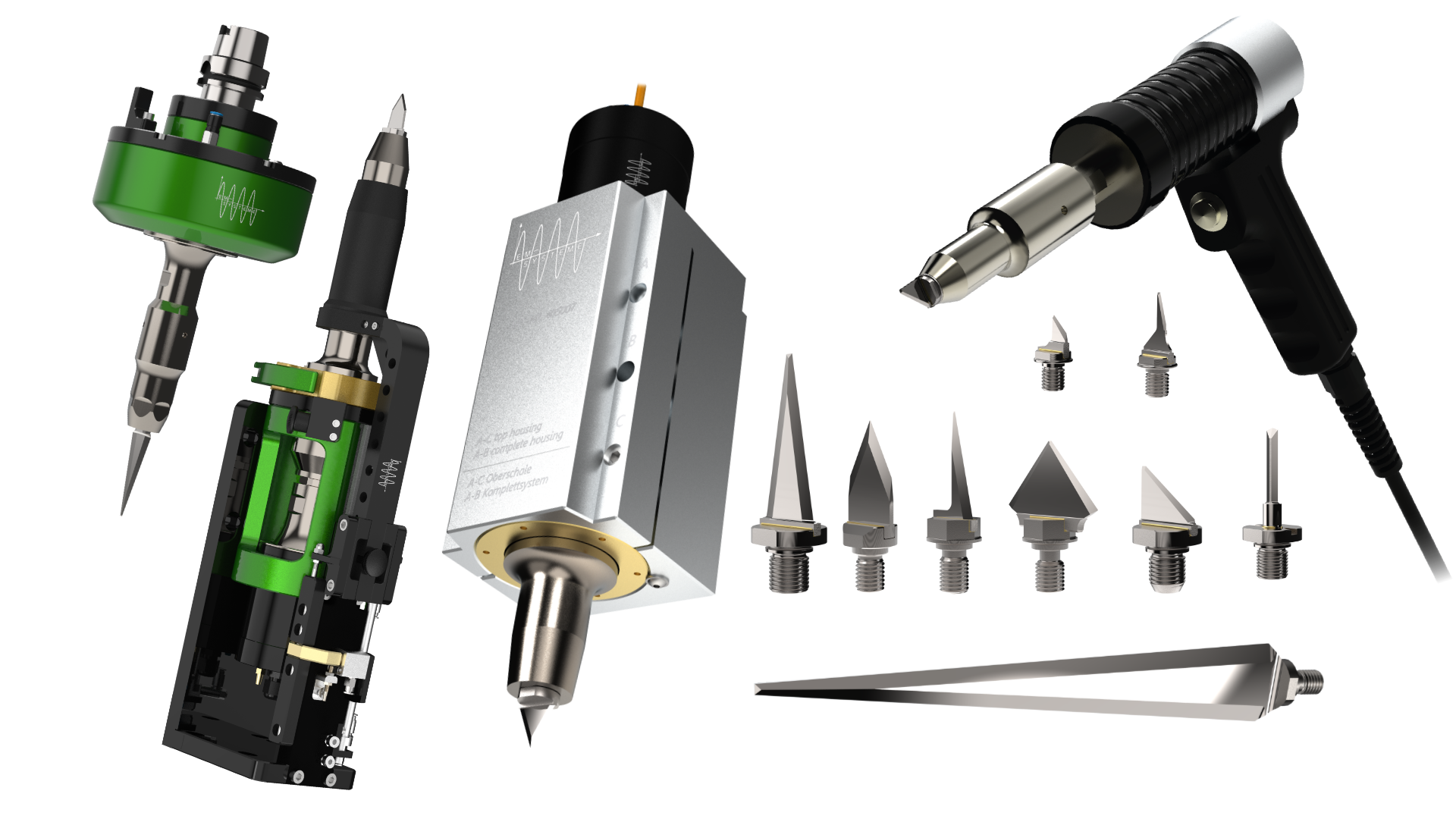

Ultraschall-Klingenschnitt

Hochfeste Fasern wie z.B. Aramid, Carbon, Basalt und Glasfasern mt oder Harz gebunden werden ebenso mit Ultraschallklingen geschnitten wie Elastomere, Folien, Bodenbeläge, Kork und viele andere Materialien. Anders als beim Trennschweißen, wie man es bei Textilien kennt, wird keine Wärme beim Schneiden eingetragen. Unsere Systeme werden bereits seit über 20 Jahren eingesetzt und regelmäßig durch innovative Ideen ergänzt. Ein umfangreiches Portfolio sollte Ihren Wünschen und Anforderungen standhalten.

Mehr unter: https://www.em-systeme.de/ultraschallschneiden/ultraschall-klingenschnitt/

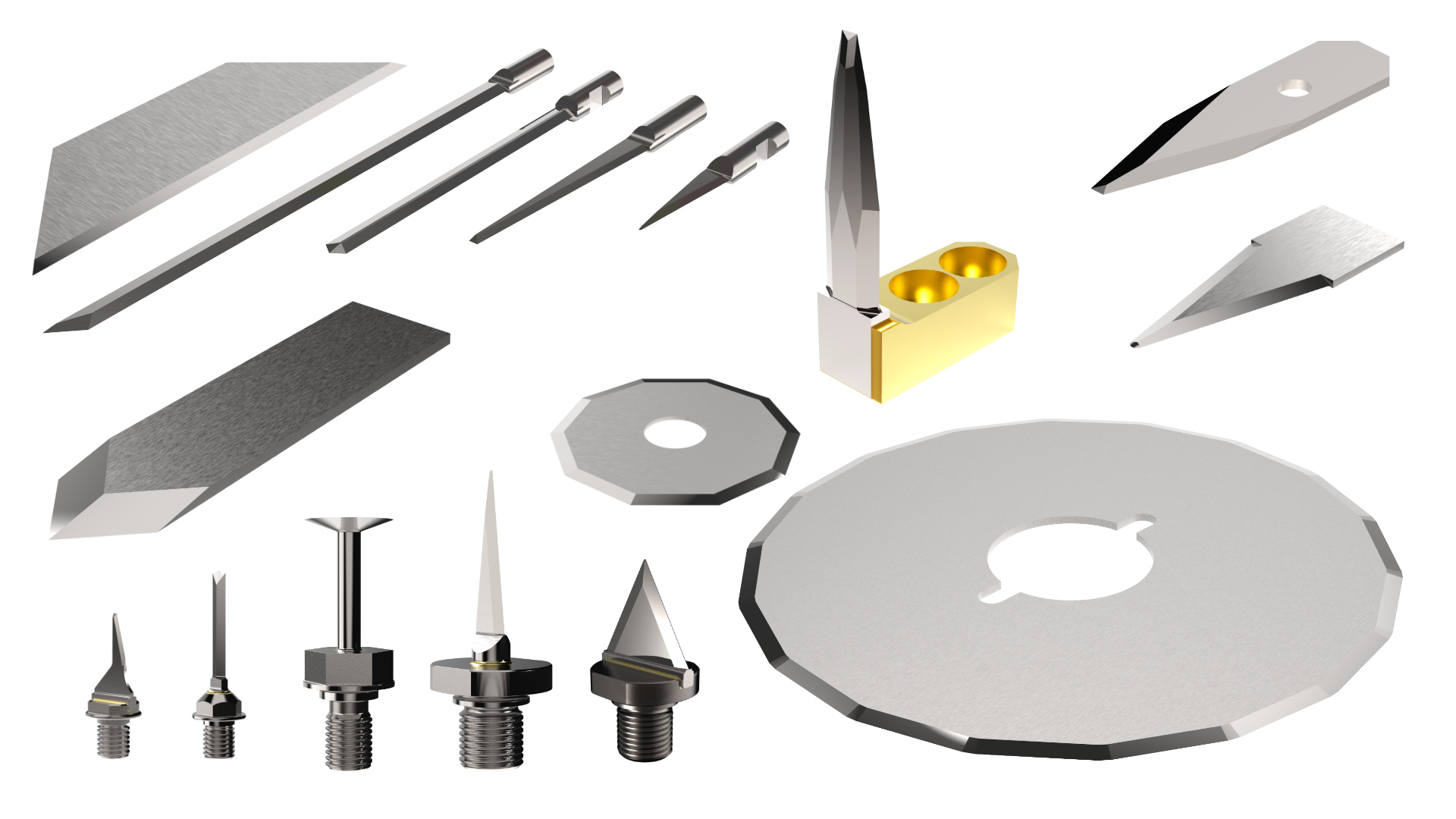

Hartmetallmesser

Die Materialauswahl bei Schneidwerkzeugen wird häufig unterschätzt. Die Stärke von EM-Systeme sind Hartmetallmesser, die auf die entsprechende Applikation abgestimmt sind. Dies können mittels Ultraschall angeregte, oszillierende oder vibrierende Klingen, Ersatz für Stahlklingen oder auch Sonderausführungen sein. Wir entwickeln Klingen für Ihren Anwendungsweck oder fertigen nach Zeichnung bzw. Skizze.

Mehr unter: https://www.em-systeme.de/hartmetallmesser/

Zubehör, Ersatzteile

Oft ist nicht die eigentliche Technologie die Herausforderung, sondern die Integration in den Produktionsprozess. Wir helfen Ihnen mit unserer Erfahrung und auch praxisbezogenem Zubehör, dass Sie einfach, schnell und kostengünstig die Integration der Komponenten umsetzen können.

Das kann eine zugeschnittene Adaptersteuerung, eine Traverse oder ein Kantenabzug sein.

Natürlich liefern nicht nur für unser Geräte Sonoroden und Schneidräder sondern auch für Wettbewerbssysteme. Unsere eigene Fertigung am Standort Oberhausen (NRW) erlaubt uns eine schnelle Reaktion und hohe Qualität.

Mehr unter: https://www.em-systeme.de/#anwendungen

Unsere Ansprechpersonen

Jürgen Keppel

Geschäftsleitung

Geschäftsführer*in

Telefon+49 208 4090800

Oliver Petersen

Vertrieb

Angestellte*r