Screw extruders

Beschreibung

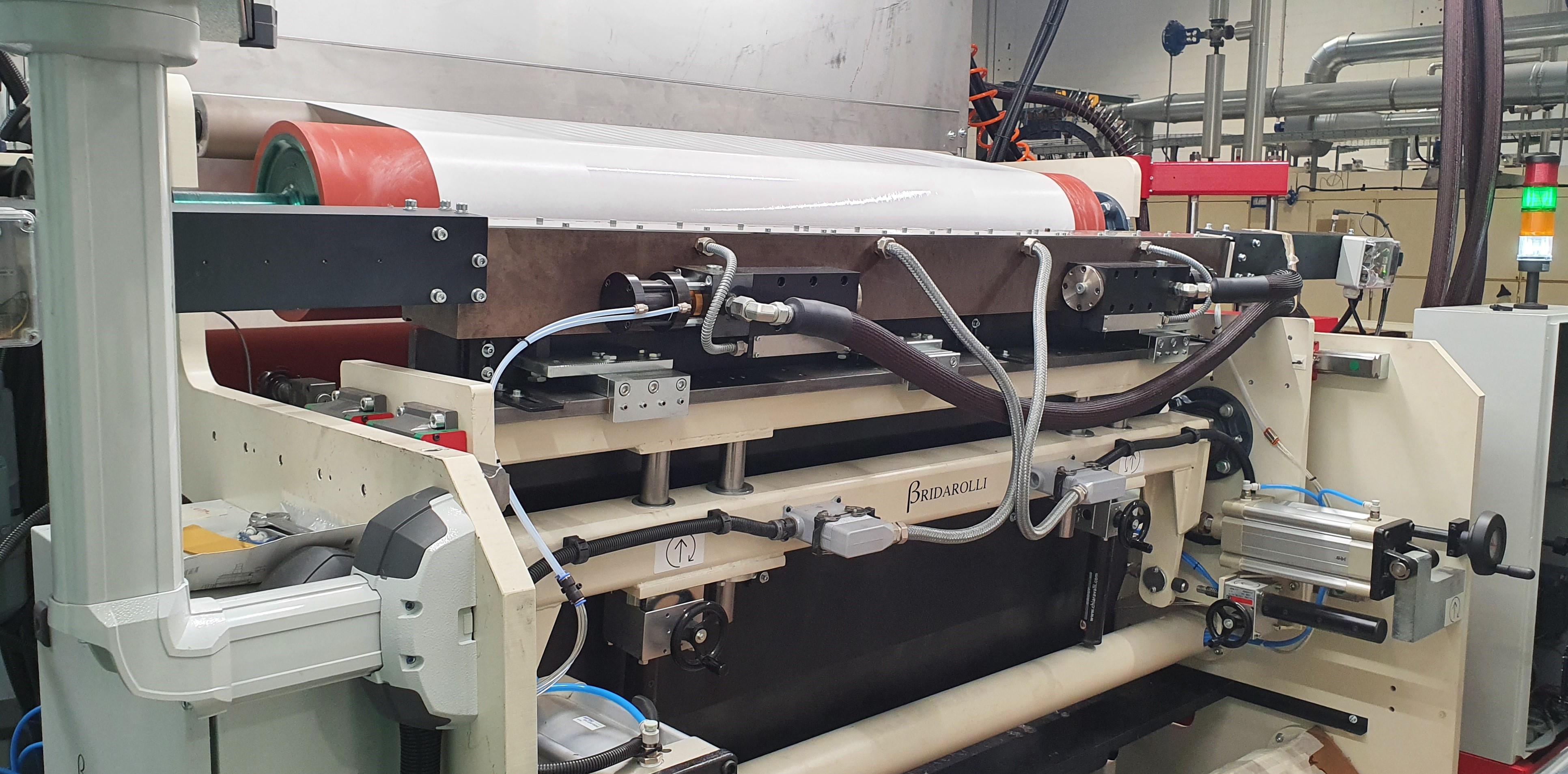

BE range screw extruders are mainly used for melting hot melt and thermoplastic granules adhesives.

Basically extruders have been engineered in order to face all those adhesives which are difficult to be melted, which require an high operative temperature and are characterized by an high viscosity, compared to all other adhesives normally processed with tank melters.

BE range screw extruders are mainly used with thermoplastics, TPU, polyamides, polyesters and in general with all those adhesives which tend to oxidize.

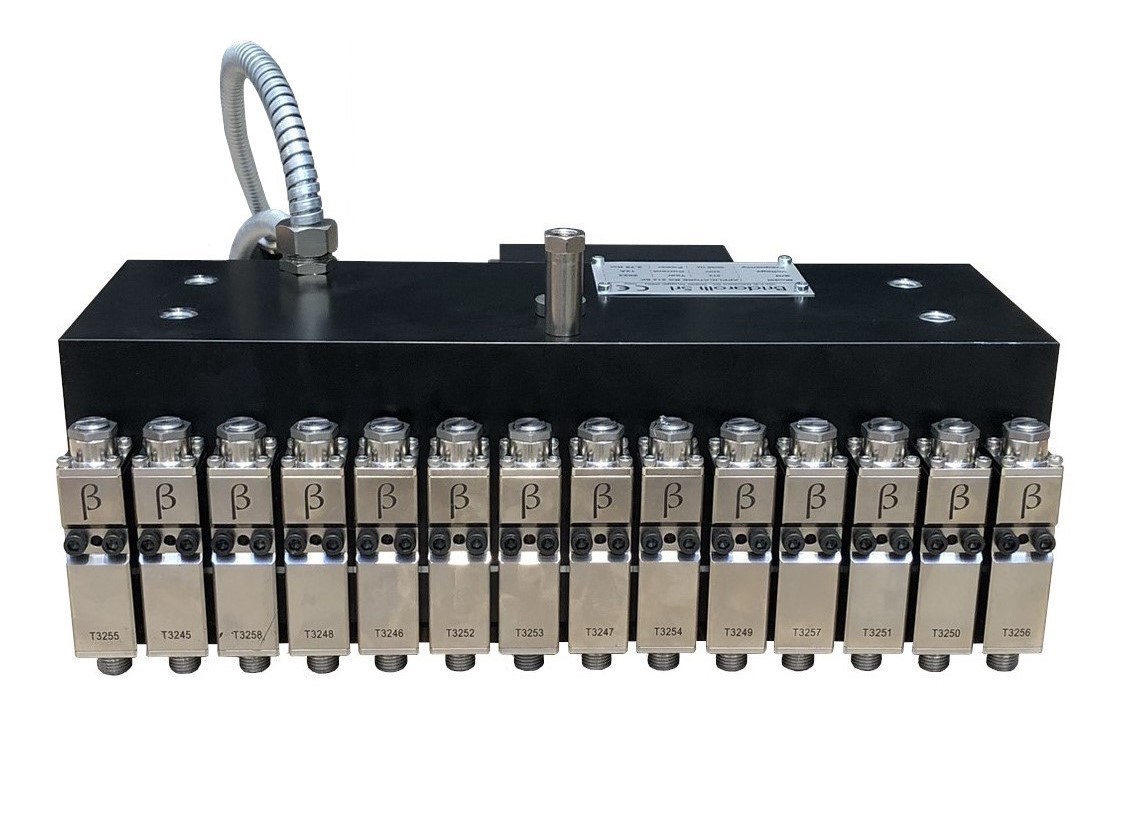

BE range screw extruders dispose of a particular extrusion screw, designed according to the type of adhesive to be melted.

All extruders are also equipped with remote assistance.

- Special granules feeding system for adhesives requiring a low melting temperature

- Possibility to work in extruder full mouth mode or empty mouth mode

- OPTIONAL: arrangement for degassing system

- Siemens touch screen operator panel

TYPES OF ADHESIVES:

polyester

polyamides

polyethylene

TPU

PU

TECHNICAL SPECIFICATIONS:

MODEL MELTING RATE L/D MOTOR POWER HEATING ZONES

BE 18 6 - 10 kg/h 18/25 2,2 kW 3

BE 30 30 - 40 kg/h 30/30 5,5 kW 3

BE 45 60 - 80 kg/h 45/30 11 kW 3

BE 65 120 - 160 kg/h 65/30 18,5 kW 4

BE 90/25 160 - 200 kg/h 90/25 22,5 kW 4

BE 90/30 300 - 400 kg/h 90/30 30 kW 5

BE 120 500 - 600 kg/h 120/30 75 kW 6

BE 150 600 - 800 kg/h 150/30 110 kW 6

Adresse

Bridarolli S.r.l.

Via Fratelli Bandiera 9/L

20835 Muggió Monza-Brianza

Italy

Telefon+39 039 598 6639