Drum units

Beschreibung

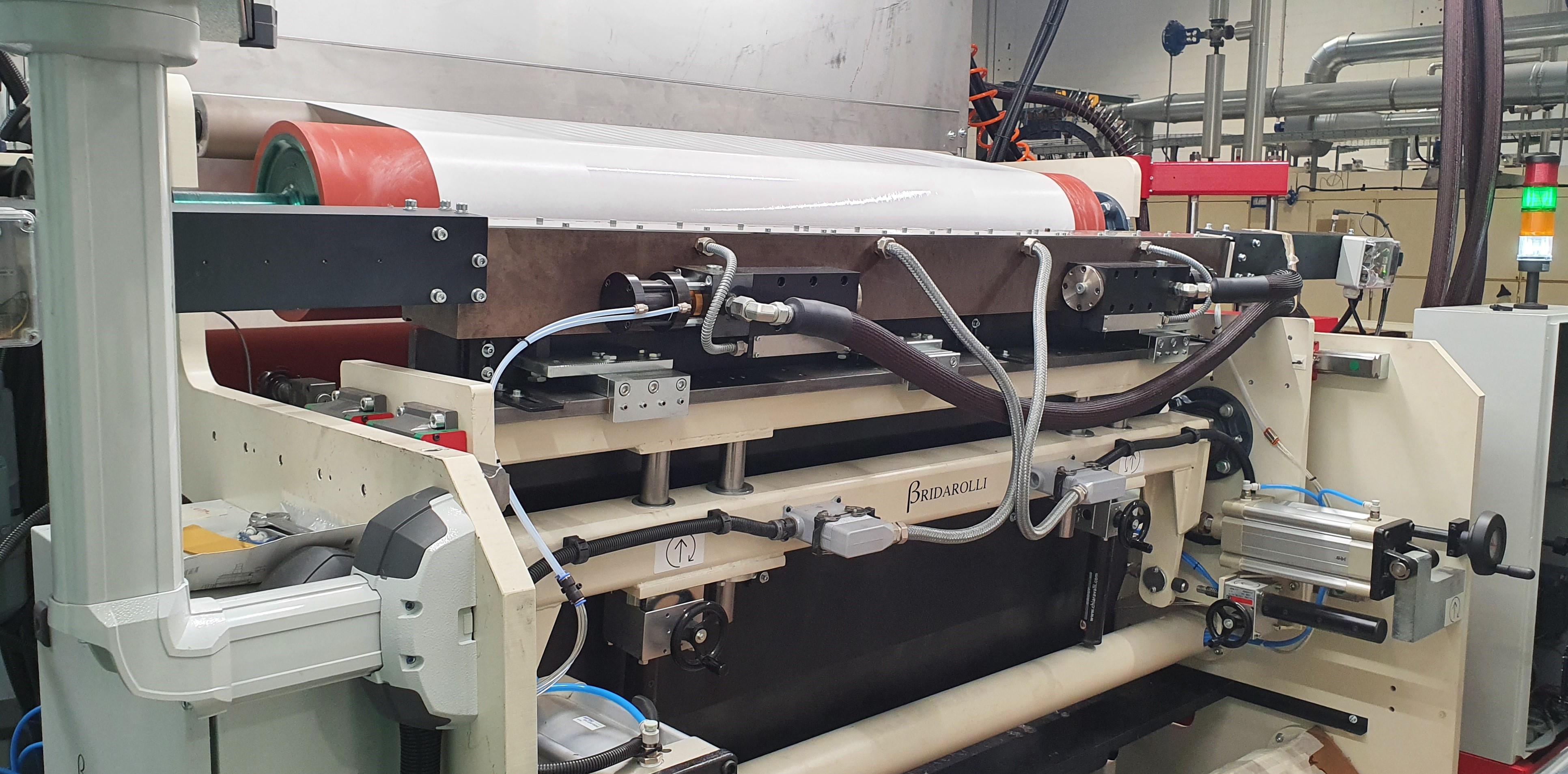

BD range drum melting units have been engineered for melting 200 lt or 20 lt barrel adhesives and are the best solution for reactive polyurethane (PUR) adhesives. These kinds of adhesives, in fact, tend to reticulate in contact with oxygen, but thanks to a teflon-coated aluminium plate covering whole drum contents, just the adhesive in contact with the plate will be melted, while the remaining inside the drum will be preserved entirely.

BD range drum melting units can also be used as premelter for the melting of self-adhesives for the following feeding of a tank unit.**

Available on request the tandem working mode for two drum units, in order to avoid the stop of the productive cycle during drum exchange.

All drum melting units are also equipped with remote assistance.

TYPES OF ADHESIVES:

PUR = reactive polyurethane

UV curable

**PSA for the following use in a tank melting system

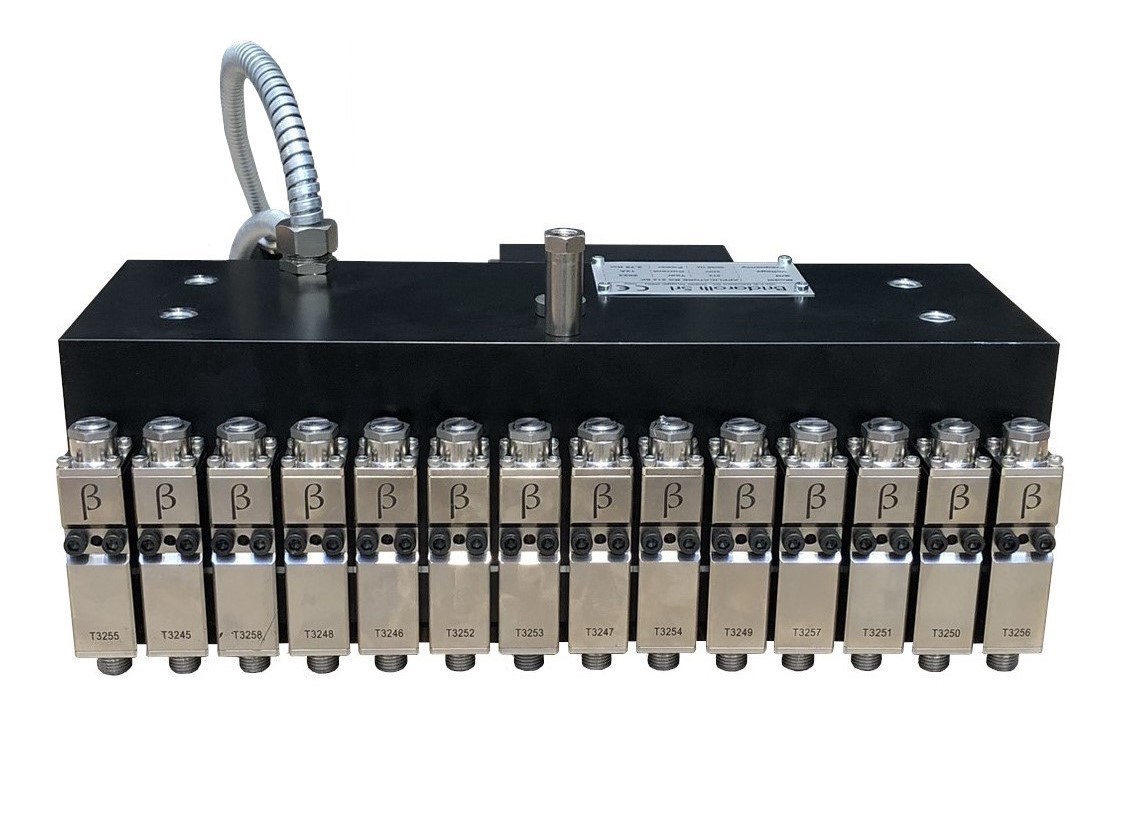

TYPES OF PLATES:

FLAT

FINNED

HIGH MELT FINNED

- Teflon-coated drip catcher in order to avoid adhesive leaks during drum exchange

- Siemens touch screen operator panel

- MELT ON DEMAND system: the drum unit melts only the adhesive part in contact with the melting plate

TECHNICAL SPECIFICATIONS:

MODEL PLATE MELTING RATE PUMP RATE

BD 200 LM Flat 20 – 30 kg/h From 48 up to 192 kg/h

BD 200 HM Finned 60 – 80 kg/h From 48 up to 192 kg/h

BD 200 HH High melt finned 100 – 120 kg/h From 48 up to 192 kg/h

BD 20 LM Flat 8 – 10 kg/h From 4,8 up to 38,4 kg/h

BD 20 HM Finned 12 – 16 kg/h From 4,8 up to 38,4 kg/h

Adresse

Bridarolli S.r.l.

Via Fratelli Bandiera 9/L

20835 Muggió Monza-Brianza

Italy

Telefon+39 039 598 6639