PI - polyimide

Beschreibung

PI (Polyimide) is a high-performance polymer with excellent high temperature resistance, chemical resistance and mechanical strength.

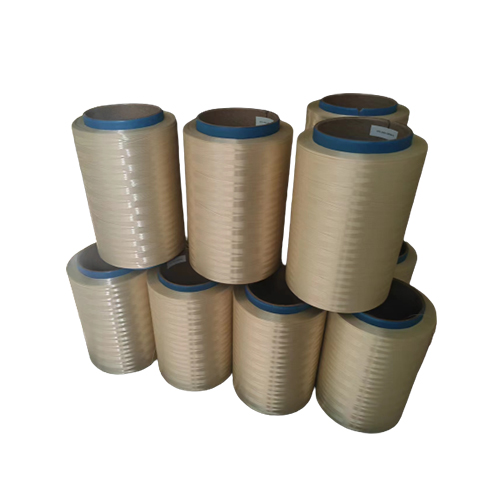

- Polyimide staple fiber:

It usually has a short fiber length, typically ranging from millimeters to several centimeters. These short fibers can be obtained by spinning, cutting, or other processing methods. Compared with long fibers, short fibers are easier to mix, disperse and process with other materials.

It can be used in applications such as reinforcing composites, filling materials and injection molding. They can provide increased strength, stiffness and heat resistance of the material, improving the mechanical properties and stability of the material. In addition, polyimide staple fibers can also be used to manufacture insulation materials, sealing materials, friction materials and so on.

The characteristics of polyimide staple fibers include good high temperature resistance, excellent chemical stability and mechanical strength, making them important in a variety of demanding applications.

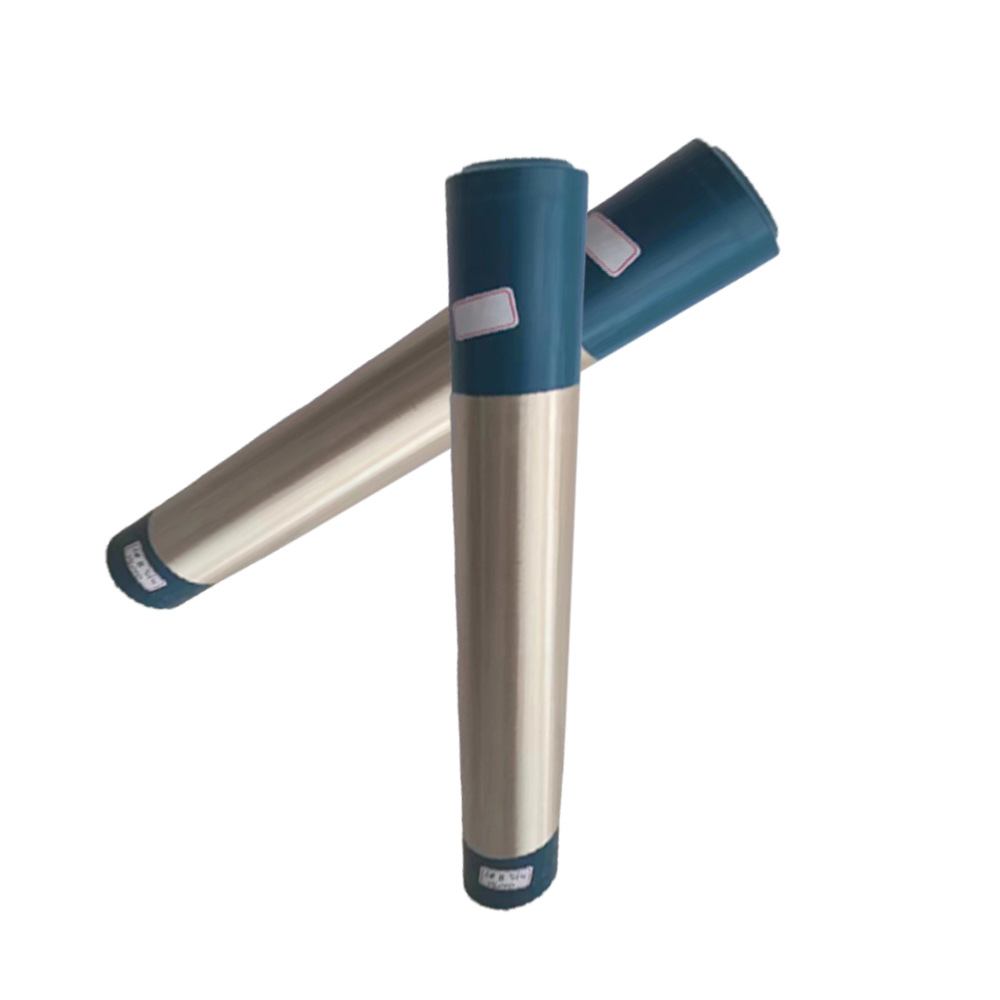

- High temperature resistant polyimide long fibre

It is a fiber material with excellent high temperature resistance. Polyimide is a high performance polymer whose molecular structure contains strong imide bonds, which makes it have excellent thermal stability and high temperature resistance. This long fiber usually exists in continuous fiber form, which can maintain its strength and durability in high temperature environments.

It is widely used in aerospace, automotive, electronics, military and other fields of high temperature environment. They can be used to manufacture high temperature seals, electrical insulation materials, high temperature resistant filters, composite reinforcers, etc. Due to its excellent high temperature resistance and mechanical strength, high temperature resistant polyimide long fibers are ideal for many high temperature applications.

- High strength high modulus polyimide long fibre

It usually exists in the form of continuous fibers with high tensile strength and stiffness. This means that they can withstand large tensile forces when stressed, while having excellent flexural and compressive properties. In addition, this fiber also has a low coefficient of thermal expansion and good heat resistance, which can maintain its strength and stability in high temperature environments.

It is widely used in aerospace, automobile, ship, sports equipment and other fields, including the manufacture of composite materials, reinforcement materials, structural parts and so on. Its excellent mechanical properties make it ideal for many applications requiring light weight, high strength and high stiffness.

- Polyimide silver plated nickel plated fiber

It is a composite material, it is made of polyimide (PI) fiber after silver and nickel plating treatment. This material has high strength and electrical conductivity and is suitable for electronics, conductive textiles and other high-tech applications. Silver and nickel plating treatments can increase the electrical conductivity and corrosion resistance of the fiber, while improving its mechanical properties.

Adresse

PALDEK INTERNATIONAL GmbH

Röddelinseeweg 9

13599 Berlin

Germany

Telefon+49 30 80939257

Fax+49 30 52650638