PALDEK INTERNATIONAL GmbH

PVDF - polyvinylidene fluoride

Zum Produkt

LCP - polyaryl ester filament fiber

Zum Produkt

PI - polyimide

Zum Produkt

PEEK-Polyether ether ketone fiber

Zum Produkt

PTFE - Teflon

Zum Produkt

PVDF - polyvinylidene fluoride

Zum Produkt

LCP - polyaryl ester filament fiber

Zum Produkt

PI - polyimide

Zum Produkt

PEEK-Polyether ether ketone fiber

Zum Produkt

PTFE - Teflon

Zum Produkt

PVDF - polyvinylidene fluoride

Zum Produkt

LCP - polyaryl ester filament fiber

Zum Produkt

PI - polyimide

Zum Produkt

PEEK-Polyether ether ketone fiber

Zum Produkt

PTFE - Teflon

Zum ProduktAdresse

PALDEK INTERNATIONAL GmbH

Röddelinseeweg 9

13599 Berlin

Germany

Telefon+49 30 80939257

Fax+49 30 52650638

Entdecken Sie mehr von uns

Über uns

The former company of PALDEK was founded in 1980,who was researched,developed and production for all kinds of filtration products with university of technology in Germany and China.

In 2003, PALDEK international GmbH established Suzhou PALDEK filtration system technology co., LTD in Asia (Suzhou, China) with independent autonomy and self - import and export license.

PALDEK has been engaged in OEM manufacturing for European and American enterprises for many years. Through years of technical accumulation and self-developed in filtration materials, PALDEK has developed a series of (liquid, gas and solid) filtration products, widely replacing the filtration products of various European and American brands in the international market.

PALDEK’s technology research and develop center equipped with professional filter material precision detector, scanning electron microscope, filter material porosity detector, detector efficiency, the filter material material analyzer, thickness meter, filter through the test bench for many times, filter filtration index detection machines, laser granularity oil detector and other advanced imported equipment, can provide professional technical service to the user immediately, at the same time for a variety of filtration products and product data, performance testing, to ensure the product quality assurance.

in recent years, PALDEK has continued its research and exploration in the field of materials. In 2020 a new branch- KUPU special Materials (Suzhou) Co., LTD., was established in Suzhou China, which specializing in the production and sale of high-performance materials.

KUPU are mainly engaged in liquid crystal polymer (LCP), polyether ether ketone (PEEK), polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), polyphenyl ether (PBO), polyimide (PI) and various high-performance particles and other products. As a leading supplier, our products are widely used in the electronics, aerospace, medical, automotive and energy sectors. We offer high-quality films, fiber cloths and particles with superior mechanical properties, chemical resistance, thermal stability and electrical insulation properties.

At KUPU, we are committed to working closely with our customers to understand their needs and provide innovative solutions. We have a professional research and development team to continuously promote technological innovation and product development. Through continuous research and development, we can not only meet the individual needs of customers, but also lead the development trend of the market.

Our mission is to provide our customers with high quality materials that help them achieve higher performance and benefits in a variety of industries. We focus not only on product quality and technological innovation, but also on environmental protection and sustainable development.

PALDEK and KUPU products:

- High performance special filber: LCP, PEEK PTFE, PVDF, Aramid, polyimide and other fibers, fiber cloth, polyaryl ester film. Imported special fiber grade, injection grade raw materials. Fiber, mesh specifications: 10D-1600D. Finished fabric specifications: 20-300 mesh, can be customized according to customer requirements.

- Filter material: wood fiber filter material, cotton fiber filter material, cotton fiber filter core, nano fiber filter material, electrostatic spider nano-spinning composite filter material.

- Filtration equipment: Oil mist purification recovery unit, VOCS purification device, waste oil purification treatment device, emulsion concentration processing equipment, multi-functional (high viscosity) filter oil cars, EH phosphate ester fire-resistant oil acid oil filter machine, oil filter purification flushing device, vacuum coalescence filter oil machine, multi-function oil-water separation filter oil machine, sewage treatment plant, air dust filter cartridge, welding smoke dust catcher, warehouse top filter, dust filter bag, liquid filter bag, automatic backwash filter, high pressure filter, the switching type double cylinder big flow filter, filter core, PU filter tube, stainless steel filter cartridge folding, resin capture filters,Stainless steel qire-type wire winding (screen tube, screen plate), sintered filter, stainless steel filter, PP (nylon) melting spray filter, PP (absorbent cotton) winding filter, PE folding filter, design customized non-standard filter, hydraulic, lubrication system transformation.Undertake oil filtration, pipeline flushing, and online oil NAS testing projects.

Europe (Germany):

PALDEK INTERNATIONAL GmbH

Röddelinseeweg 9

13599 Berlin-Haselhorst

Tel: +49 (0)30 - 8093 9257

Fax: +49 (0)30- 5265 0638

Email: info@paldek.de

Asia (China):

Suzhou Paldek Filtration Science &Technology Co. Ltd

Kupu special Material (Suzhou) Co. Ltd.

NO.25 ChenYang Renmin Rd

Economic development zone,

215600, Zhangjiagang city, JiangSu Province , China

Tel: +86 (0)512-5873 0300, 58730200-8001

Fax: +86 (0)512-58916366

Email: paldek@126.com

Website:

www.paldek.de - Paldek International GmbH

www.paldek.com - Suzhou Paldek Filtration Science &Technology Co., LTD

www.kuputc.com - Kupu special Material (Suzhou) Co. Ltd.

Unsere Produktgruppen

- Fibres and Yarns

Unsere Anwendungsbereiche / Lösungen

Downloads

Dokumente

Keywords

- LCP (polyaryl ester fiber), PEEK (polyether ether ketone)

- PTFE(Teflon), PVDF(polyvinylidene fluoride), PBO, AR(Aramid)

- PBO(polyp-phenylene benzoxazole), PI(polyimide)

- High performance particle, Thin film, Fiber cloth

- Filtration equipment and Filter material

Unsere Produkte

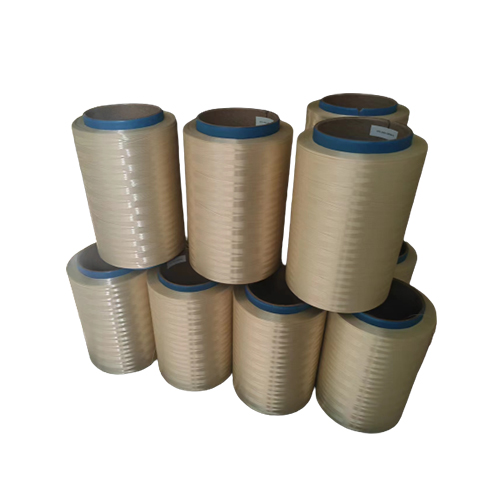

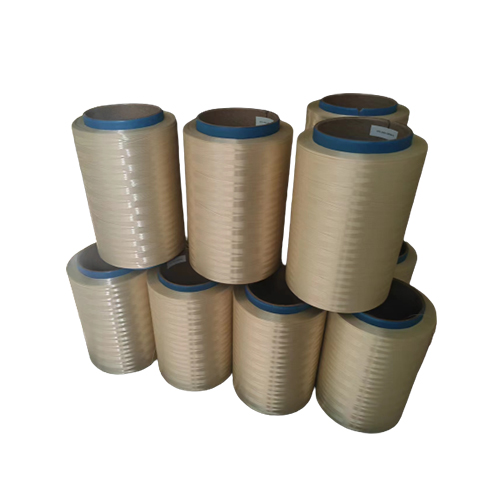

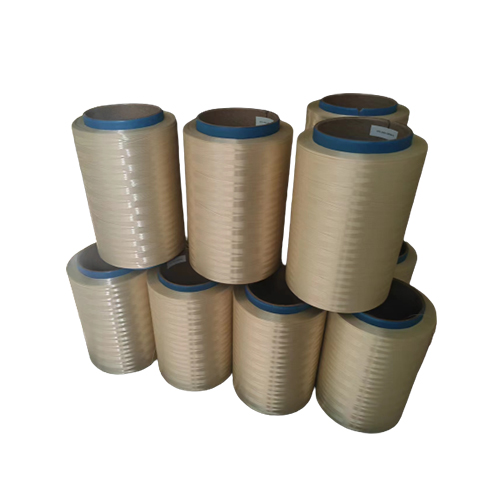

PVDF - polyvinylidene fluoride

PVDF filament fiber is made of Polyvinylidene fluoride (PVDF) continuous fiber. PVDF is a high performance synthetic polymer with excellent chemical stability, heat resistance and mechanical strength. PVDF filament fibers are often used in textile, filtration, batteries, sensors and other fields. It is resistant to corrosion, UV, fatigue and wear, so it is widely used in different industrial applications.

LCP - polyaryl ester filament fiber

LCP (polyaryl ester filament fiber), is a fiber made of liquid crystal polymer. The fibers have high strength, high modulus and heat resistance, and they Orient during stretching to give them anisotropic properties. It is commonly used in areas such as high-performance textiles, electronics and reinforcement materials in industrial applications.

LCP fiber specifications : 50D, 55D, 100D, 200D, 400D, 1000D, 1500D, 3000D etc.

- LCP hardshell fabric

LCP is commonly used as a hardshell fabric in military and outdoor clothing. LCP has many excellent characteristics, including high strength, low weight, wear resistance, flame retardant and chemical corrosion resistance. It also has good tear resistance and good barrier property, which can effectively protect the human body from the external environment.

LCP hardshell fabric is usually a three-layer composite structure, where the outer layer is made of LCP fiber, the middle layer is often a breathable film to provide waterproof and moisture permeability, and the inner layer is usually a comfortable lining fabric. This design can keep the body dry while providing excellent wind, water and moisture resistance to combat or outdoor activities in a variety of adverse weather conditions.

In short, LCP hardshell fabric is widely used in the military and outdoor fields with its excellent performance and multi-functional characteristics, and provides reliable protection and comfort.

PI - polyimide

PI (Polyimide) is a high-performance polymer with excellent high temperature resistance, chemical resistance and mechanical strength.

- Polyimide staple fiber:

It usually has a short fiber length, typically ranging from millimeters to several centimeters. These short fibers can be obtained by spinning, cutting, or other processing methods. Compared with long fibers, short fibers are easier to mix, disperse and process with other materials.

It can be used in applications such as reinforcing composites, filling materials and injection molding. They can provide increased strength, stiffness and heat resistance of the material, improving the mechanical properties and stability of the material. In addition, polyimide staple fibers can also be used to manufacture insulation materials, sealing materials, friction materials and so on.

The characteristics of polyimide staple fibers include good high temperature resistance, excellent chemical stability and mechanical strength, making them important in a variety of demanding applications.

- High temperature resistant polyimide long fibre

It is a fiber material with excellent high temperature resistance. Polyimide is a high performance polymer whose molecular structure contains strong imide bonds, which makes it have excellent thermal stability and high temperature resistance. This long fiber usually exists in continuous fiber form, which can maintain its strength and durability in high temperature environments.

It is widely used in aerospace, automotive, electronics, military and other fields of high temperature environment. They can be used to manufacture high temperature seals, electrical insulation materials, high temperature resistant filters, composite reinforcers, etc. Due to its excellent high temperature resistance and mechanical strength, high temperature resistant polyimide long fibers are ideal for many high temperature applications.

- High strength high modulus polyimide long fibre

It usually exists in the form of continuous fibers with high tensile strength and stiffness. This means that they can withstand large tensile forces when stressed, while having excellent flexural and compressive properties. In addition, this fiber also has a low coefficient of thermal expansion and good heat resistance, which can maintain its strength and stability in high temperature environments.

It is widely used in aerospace, automobile, ship, sports equipment and other fields, including the manufacture of composite materials, reinforcement materials, structural parts and so on. Its excellent mechanical properties make it ideal for many applications requiring light weight, high strength and high stiffness.

- Polyimide silver plated nickel plated fiber

It is a composite material, it is made of polyimide (PI) fiber after silver and nickel plating treatment. This material has high strength and electrical conductivity and is suitable for electronics, conductive textiles and other high-tech applications. Silver and nickel plating treatments can increase the electrical conductivity and corrosion resistance of the fiber, while improving its mechanical properties.

PEEK-Polyether ether ketone fiber

PEEK(Polyether ether ketone fiber) is a kind of all-aromatic fiber, and there are ether bonds and ketone bonds, so that the fiber's high temperature resistance, friction resistance, corrosion resistance is much higher than the conventional fiber. Polyether ether ketone fiber is mainly used in aerospace, weapons and equipment required structural parts of the mixed composite material, aerospace high performance wire and cable braided sheath and civil field of paper machinery dry canvas, heat resistant filter cloth, heat resistant corrosion textile belt, composite materials (with glass fiber, carbon fiber mixed), energy industry high temperature resistant materials.

Monofilament diameter (mm) : 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

Filament Specification dTex/F(D/F) : 128dTex/30F (115D/30F), 138dTex/30F (125D/30F), 276dTex/60F(250D/60F), 552dTex/120F(500D/120F), 1230 dTex/120F(1107D/120F).

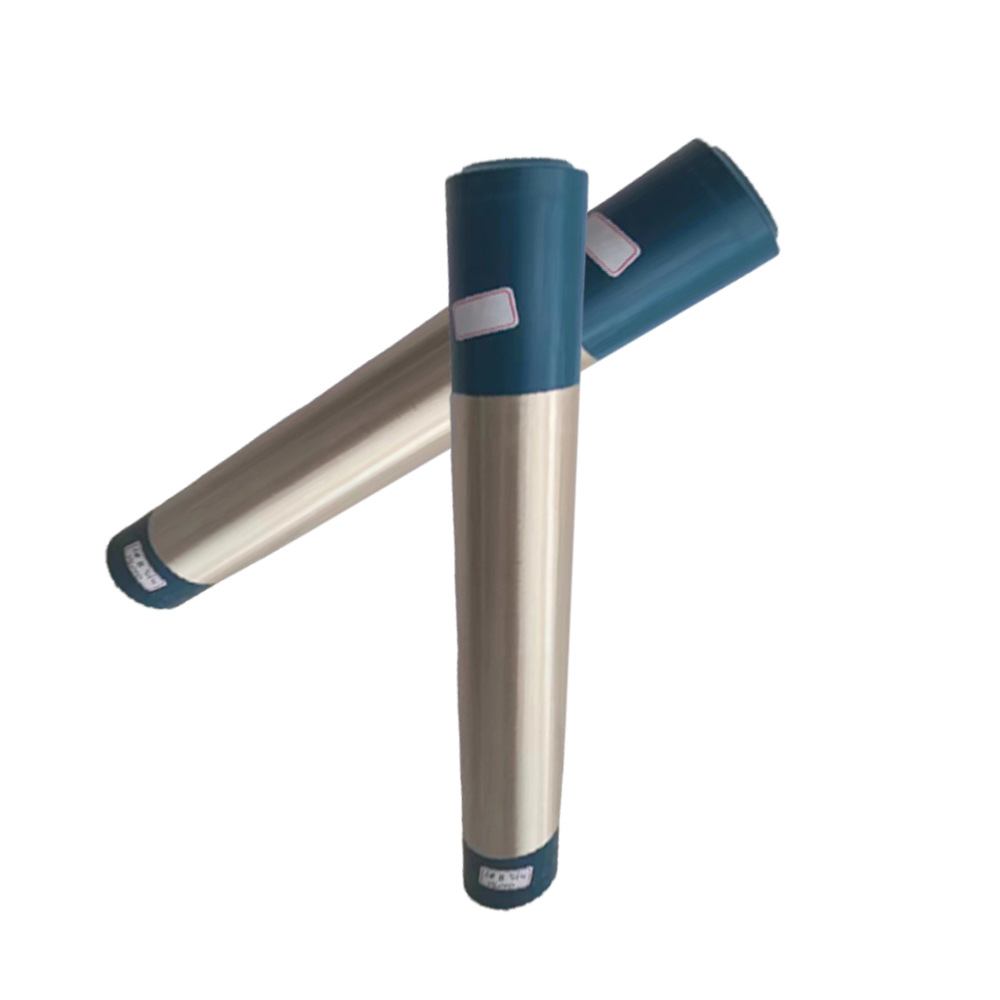

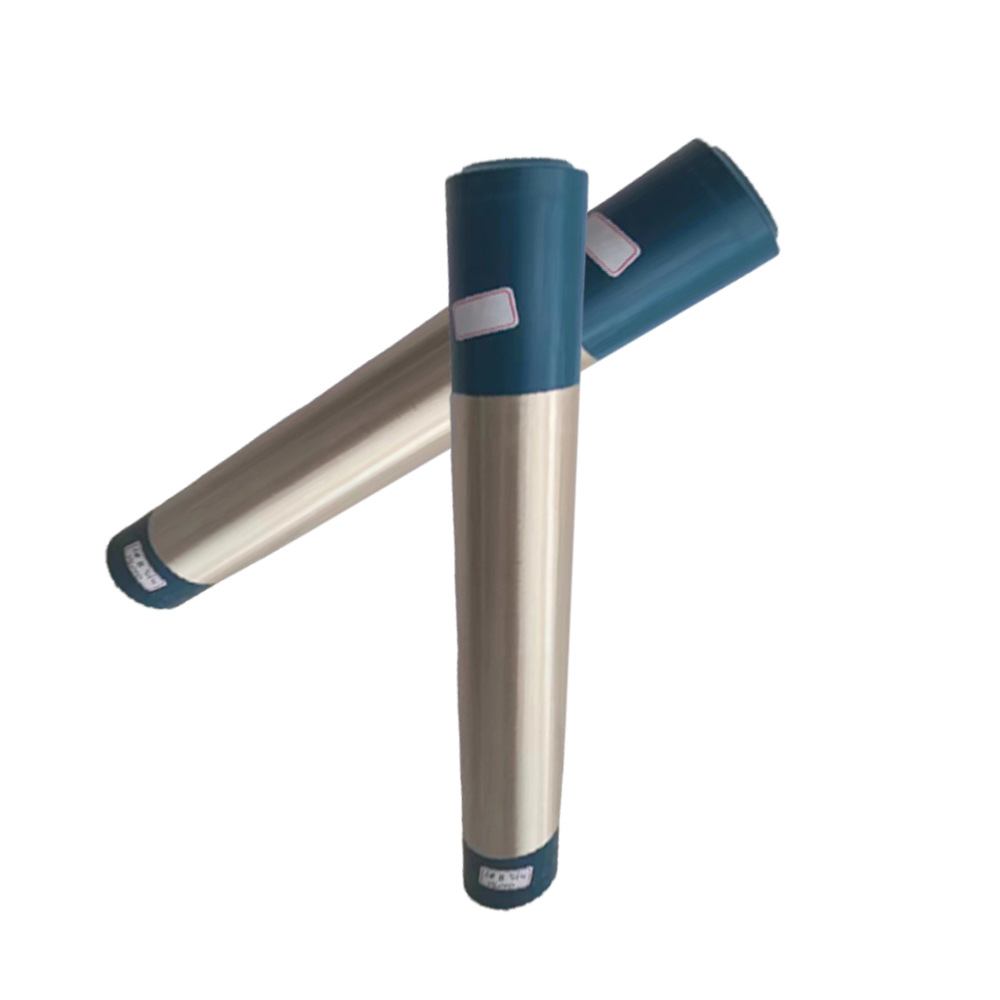

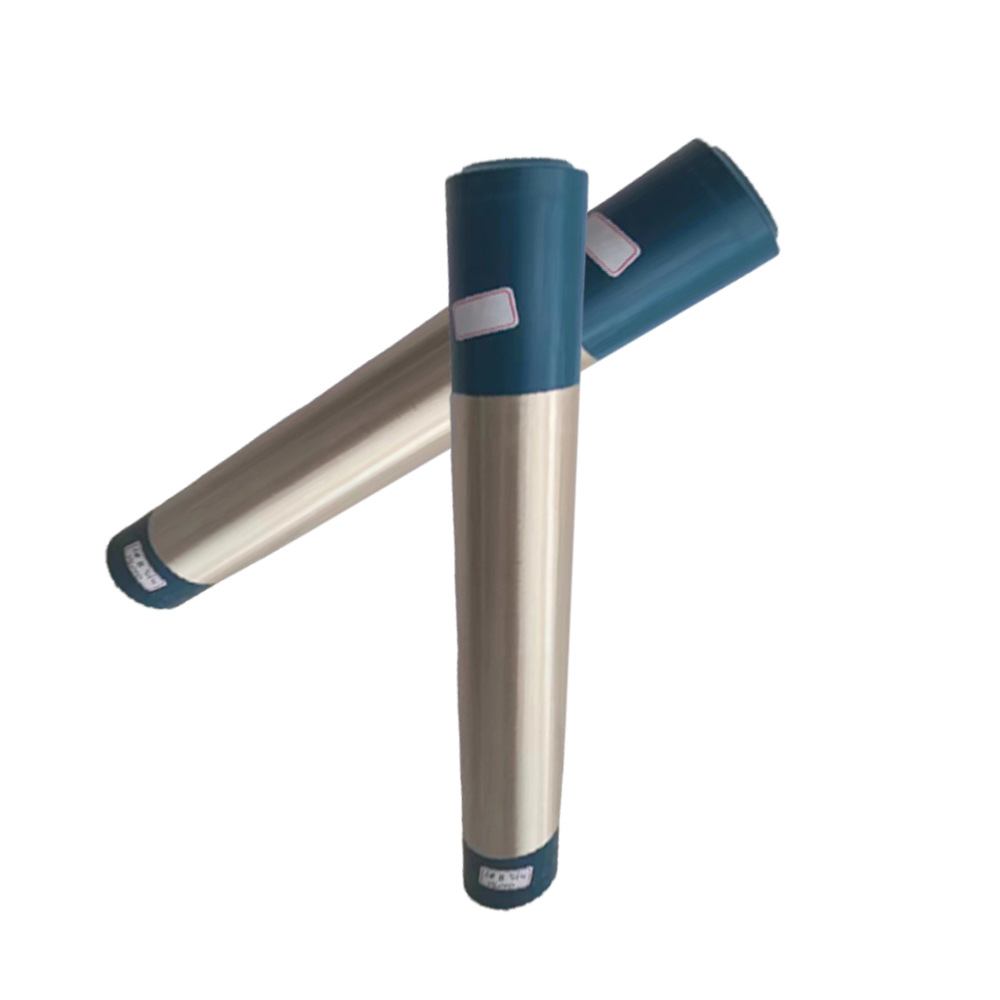

PTFE - Teflon

Kuputc PTFE filament, produced by "paste extrusion" process, has the characteristics of round wire diameter, uniform dry strip, large modulus (stiffness), no hair, etc., is the preferred material for weaving liquid filter cloth, spunlace base cloth, chemical drying net. Product line density specifications from 90dtex (80D) to 2200dtex (2000D), can be designed and produced according to customer needs.

The top product of Kuputc is 90dtex ~220dtex low-dener silk, which is the best material for chemical filtration nets such as chlor-alkali filter membrane skeleton net, filling the gap in Chinese manufacturing.

Kuputc can provide dozens of color filaments, in addition to excellent temperature resistance, corrosion resistance, color saturation, bright, high color fastness, UV radiation resistance. With its woven awning cloth, it is especially suitable for the shading project of high-end buildings and tourist resorts in the Marine island environment.

Kuputc can also provide various sizes of biological and medical filaments.

These filament products from Kuputc are produced by the re-finishing process of extruded filament and are available as single filament (round filament, flat filament) and multi-stranded filament (< 6F composite silk) shape, can be recommended according to customer requirements.

- PTFE sewing thread

It is the preferred thread for the sewing of high-end filter bags in bag dust removal technology. Products are mainly used for polytetrafluoroethylene (PTFE) temperature resistance, corrosion resistance, oxidation resistance and other excellent material properties to ensure that the quality of the filter bag can be suitable for high temperature and corrosive gas emissions and other harsh conditions such as dust filtration.

- colored sewing thread

It is made by adding nano-scale fluoro pigment to the polytetrafluoroethylene dispersion resin, with a unique patented blending technology. While maintaining the excellent characteristics of PTFE temperature resistance and corrosion resistance, the product has the characteristics of full color, oxidation resistance and high fastness to sunlight.

Color sewing thread is mainly used for sewing special industrial powder (mineral powder) collection filter bag, dust filter bag, screen identification, as well as sailing sails, awning tarpaulin and so on.

Color sewing thread density specifications are 1350~5500dtex, can accept special color customization.

- Polytetrafluoroethylene rope

It is an extension of silk wire products, take silk braid or wire braid, rope braid process production, the rope has a dense appearance, stiff, no burrs, hair. Products are used in aviation, chemical industry, Marine aquaculture and other fields.

Kuputc PTFE rope according to the wire diameter set and gram weight for the standard design knitting process, can be designed wire diameter 1mm~20mm products, gram weight specifications and strength requirements, can be designed according to customer requirements.

Kuputc produces colorful PTFE rope products according to the design.