Die Aussteller & Produkte der Techtextil 2026 finden Sie ab Mitte Januar 2026 hier.

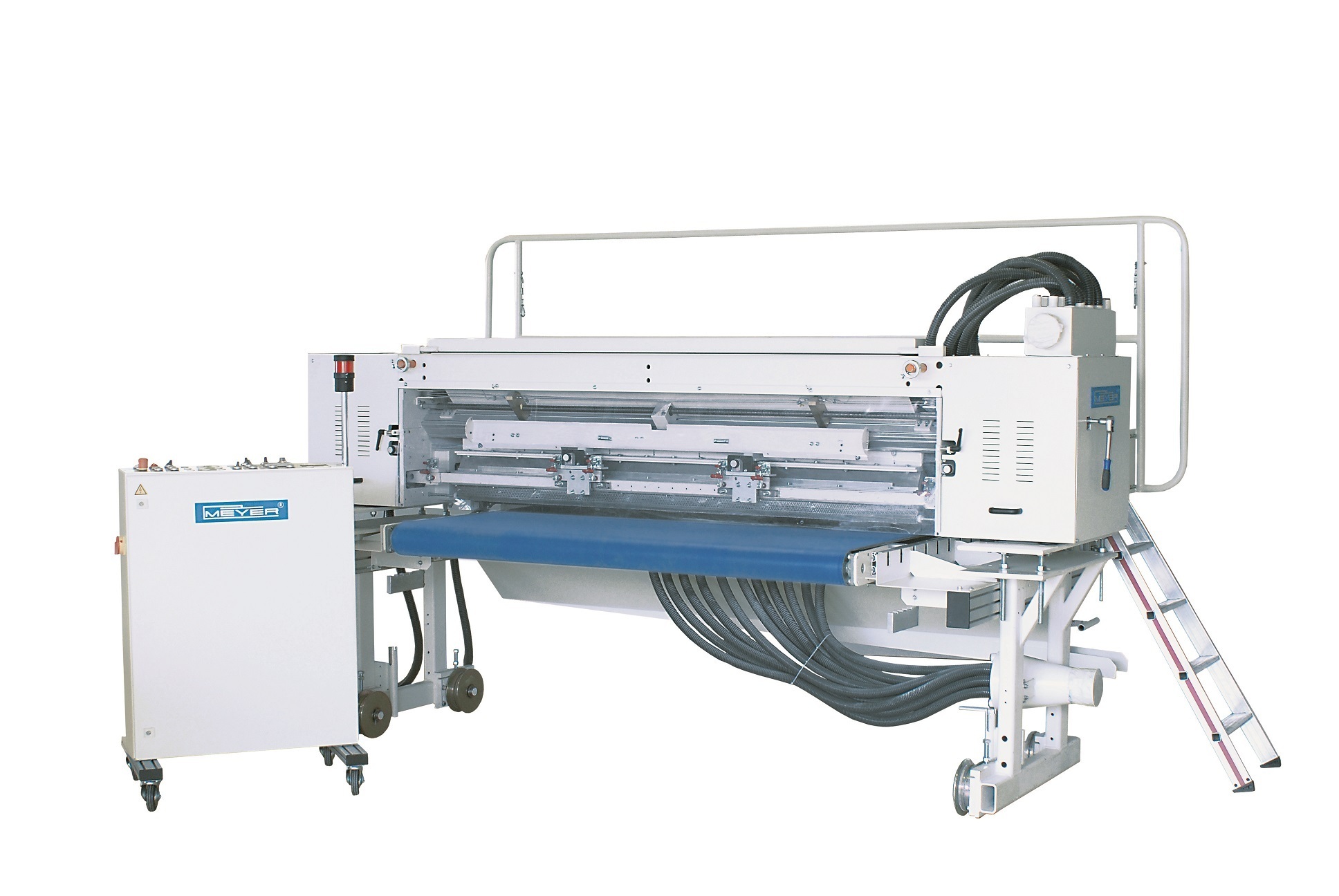

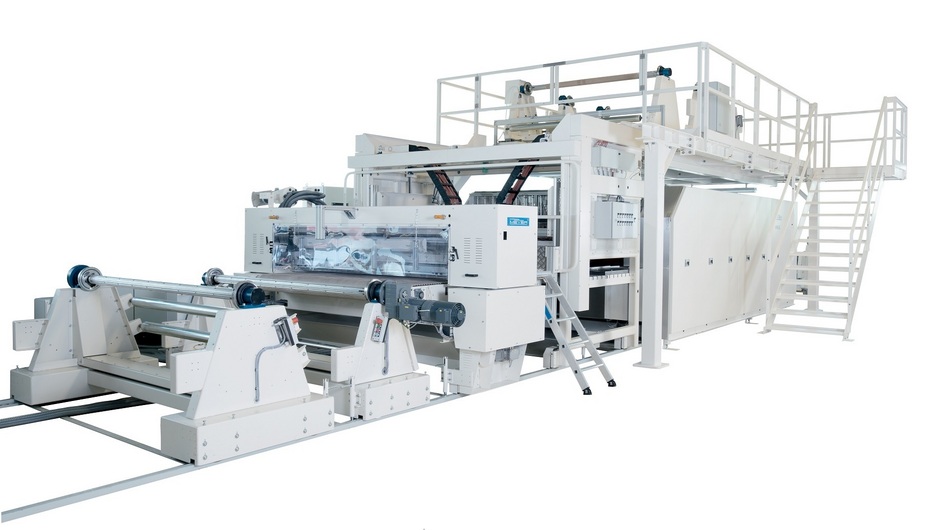

Flachbettkaschiermaschine KFK

Flachbettkaschiermaschine KFK

Beschreibung

Flachbettkaschiermaschinen in verschiedensten Ausführungen mit entsprechender Peripherie gem. Kundenanforderungen

MEYER Flachbett-Kaschier-Anlagen sind Doppelbandpressen mit integrierter Kontaktheizung und Kühlung. Die zu kaschierenden Materialien werden dabei schonend erwärmt. Durch die Länge der Heizzone ergibt sich eine relativ lange Verweilzeit in der Kaschierpresse, was zu einer optimalen Verklebung mit hohen Haftwerten führt. Unmittelbar nach der Heizzone kann das Kaschiergut mit den Kalanderwalzen verpresst, oder auf eine gewünschte Endstärke kalibriert werden. Um diesen Verbund zu stabilisieren, wird das Kaschiergut noch innerhalb der Kaschieranlage abgekühlt. Durch den flachen Durchlauf und der präzisen Höhenverstellung können auch feste Platten, bis zu einer Materialstärke von 150mm kaschiert werden.

Prozessparameter

- Verweilzeit in der Heizung = Fördergeschwindigkeit

- Temperaturen in der Heizzone

- Pressdruck

- Kalibrierspalt der Presswalzen

- Höhenverstellung = Abstand der beiden Bänder

- Temperaturen in der Kühlzone

Klebstoffe

In der Regel werden thermoplastische Klebstoffe bei Meyer Flachbett Kaschieranlagen eingesetzt, da diese umweltfreundlich, einfach in der Handhabung und für nahezu jede Anwendung optimale Klebstoffe erhältlich sind. Auch die Recyclingfähigkeit oder die Anforderung bezüglich Sortenreinheit, Fogging oder Umwelt- und Gesundheitsverträglichkeit lassen sich leicht mit thermoplastischen Klebstoffen erreichen.

Je nach Anwendung und Anforderung können auch andere Klebstoffsysteme, z.B. reaktive Kleber mit Meyer Kaschieranlagen kombiniert werden.

Anwendungsgebiete:

Folienbeschichtung

Pulverbeschichtung

SK-Beschichtung

2- und Mehrlagen-Verbund

Kalibrierung

Thermofixierung

Oberflächenverfestigung