Inline quality control machines portfolio

Beschreibung

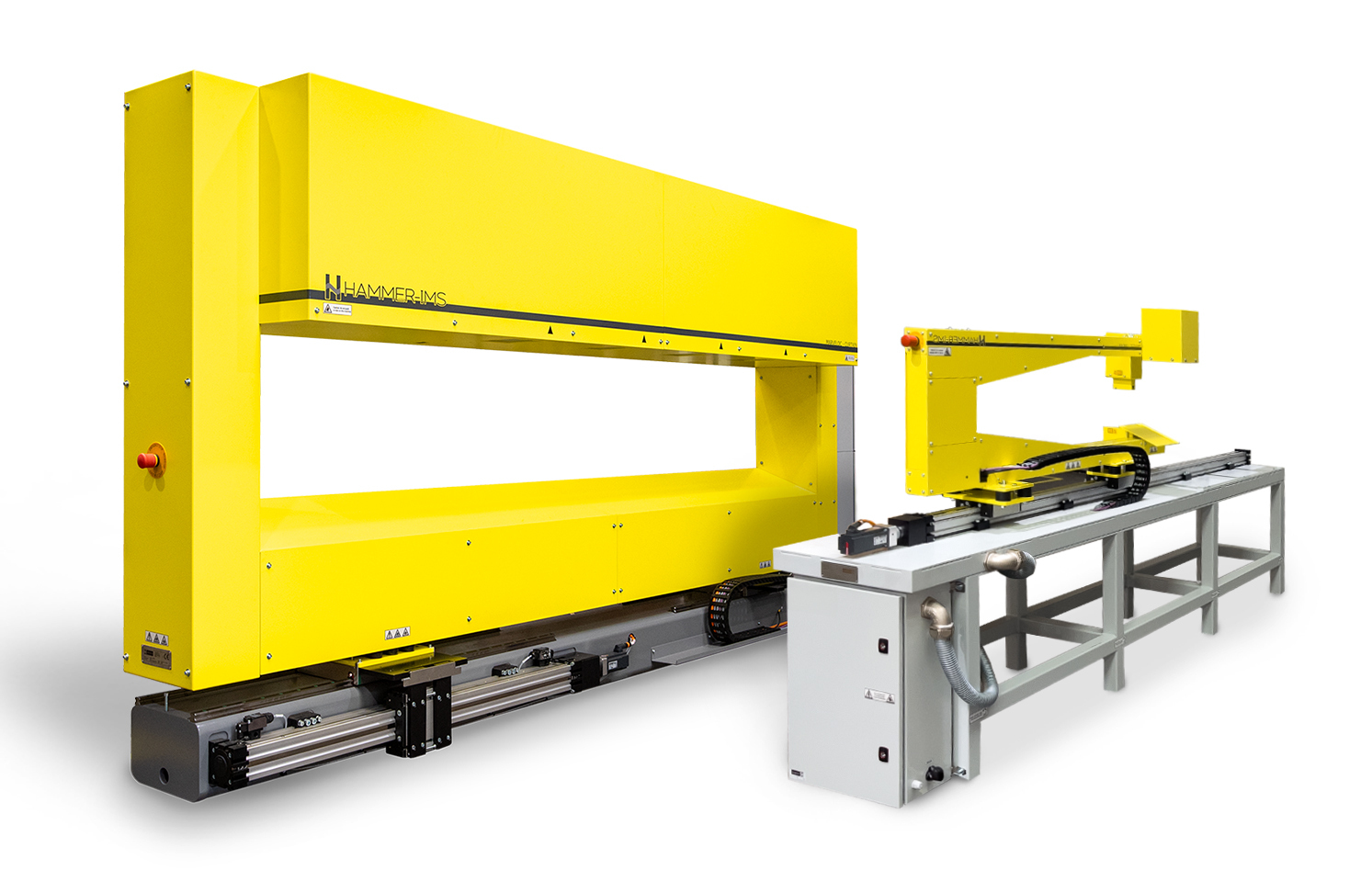

Our machines have been developed to perform measurements 24/7 as part of an industrial production line. Scanners equipped with e.g. Marveloc thickness or weight measuring sensors which typically scan the production line in transversal direction, offering nearly 100% material coverage. Our scanning machines contain both traveling-frame and traveling-head scanners. Next to machines for inline use, Hammer-IMS offers machines for OEM and laboratory systems.

Our vision technology is mounted on stationary steel constructions. The concept of ‘scanning’ is arranged by analyzing video data in transversal direction from within our control software.

Regardless whether measurement or vision technology is applied, our robust machines are equipped with Hammer-IMS Connectivity 3.0 software for easy operation and intuitive visual reporting. On request, our installations can be connected to any process management software for centralized measurement data processing and storage.

The offering of Hammer-IMS machines contain the following machine variants:

- Marveloc-CURTAIN O-frame: robust system for wide production lines exceeding 2 meters

- Marveloc-CURTAIN C-frame: robust system with arm length up to 2 meters

- Marveloc-CHARIOT: compact and affordable single-head system

As an option, Hammer-IMS offers measuring solutions ready for use in potentially explosive (EX) environments (ATEX directive). When designing measuring machines for this purpose, our engineers take into account a range of specific aspects:

- Using anti-static materials at friction-critical machine parts

- Applying qualitative grounding wiring to all machine parts

- Carefully checking temperatures of critical machine parts

- Introducing overpressure systems and overpressure security mechanisms

Note that our M-Ray technology’s wireless output power is perfectly compatible with EX-environments.

Hammer-IMS optionally offers flexibly moving the system across R&D and production. In most cases, the measuring systems of Hammer-IMS serve a specific purpose at a fixed location. However, as an option, the machine can be adapted so that it can be readily moved using built-in castor wheels or on an external rail system. In addition to inline measurements, the measuring systems can be used for R&D tasks or offline material validation work. In these cases, transportability can be a special requirement. A transportable measuring system can deliver more value in inline settings since it can be applied to multiple production lines. A transportable measuring system can deliver more value in inline settings when it is applied to multiple production lines.

In support of R&D and offline material validation, Hammer-IMS offers an optional feeder unit for any of our CURTAIN or CHARIOT machines. Typically, a feeder transports sample materials through the measuring machine for R&D purposes or offline material validation. Feeders allow material samples to be fully covered and analyzed in great detail to maintain high product quality. The compact and lightweight feeder can be operated through the Hammer-IMS Connectivity software that controls the measuring system at the same time.

To run different measurement types simultaneously, Sensor Fusion allows different types of sensors to be installed in your CURTAIN or CHARIOT-based system. For example, Hammer-IMS could integrate laser technology in our Marveloc-CURTAIN scanners. While the sensor measures nonwoven basis-weight, a laser sensor continually tracks the material thickness. In addition, the laser line sensor continuously identifies the edge of the moving nonwoven produce using enhanced-precision material edge detection.