Hammer-IMS

OEM products

Zum Produkt

Connectivity software

Zum Produkt

Marveloc non-nuclear sensors family

Zum Produkt

OEM products

Zum Produkt

Connectivity software

Zum Produkt

Marveloc non-nuclear sensors family

Zum Produkt

OEM products

Zum Produkt

Connectivity software

Zum Produkt

Marveloc non-nuclear sensors family

Zum ProduktÜber uns

Hammer-IMS bietet Marveloc-CURTAIN Dickenmessgeräte für Kunststofffolien und -platten an.

Die Extrusionswerkzeuge der Kunden können für eine reproduzierbare Produktqualität automatisch gesteuert werden. Auch Flächengewichtsmessung von Beschichtungen auf Batteriefolien und Wandverkleidungen.

Es stehen elektromagnetische, kapazitive, Ultraschall- und Lasersensoren zur Verfügung.

Die neue maschinelle Bildverarbeitungsplattform Edge-Vision-4.0 befasst sich mit Akzeptanz-/Ablehnungsproblemen und identifiziert Anomalieniveaus.

Unsere Produktgruppen

- Technology and Processes

Unsere Anwendungsbereiche / Lösungen

Mehr über uns

Special Interests

Keywords

- laboratory measurement

- inline measurement

- basis-weight measurement

- non-radioactive measurement

- non-nuclear measurement

Unsere Produkte

OEM products

The OEM product offering ranges from standard OEM modules to custom integrations.To support more in-depth and highly customized integration projects, Hammer-IMS supports the following OEM-related tracks:

- M-Ray OEM module

Hammer-IMS also offers a standard OEM module to machine builders and sensor integrators. The M-Ray OEM product is perfectly suited for such parties, as it is easy to integrate by themselves. Furthermore, the standard OEM module is for everyone: scientific researchers or enthusiasts who are passionate about non-nuclear measuring innovations. The module is sold ‘as is’ and can be accessed through our API software. The API also supports multi-sensor use of the OEM module, so you can use several OEM-modules in a single application. The OEM module comes with the embedded software and API description including demo material source code to execute your integration project at any preferred pace. Hammer-IMS can provide some assistance related to wireless regulatory and application development, where needed. In principle, this approach enables you to make your own flavor of a Marveloc-CURTAIN scanner system.

- Custom M-Ray measurement modules

Our Hammer-IMS engineers can develop and deliver custom M-Ray measurement modules and provide integration services. These custom measurement modules enable machine builders or sensor integrators to make their own integrations with thickness or basis-weight measurement capabilities delivered by Hammer-IMS. You typically select this approach when you have stringent geometrical constraints or particular non-standard integration needs. As an example, the picture below shows such an integration.

- OEM scanners

Apart from custom OEM-modules and our M-Ray OEM Module, we offer our thickness and basis-weight scanners of the type Marveloc-CURTAIN and Marveloc-CHARIOT to builders of production lines in the fields of technical textiles, nonwovens and platics extrusion. As an OEM-provider we are open to discuss the level of integration between our scanners and your production line technology. For example, when feedback is requested: would you like us to provide the motor drivers for the blade control or the power electronics to heat the thermobolts? Furthermore, to which level of extended emergency stop integration should be performed in your case. Do you require a panel pc or only a PROFINET-based interface? etc.

Hammer-IMS has recently introduced its new AEROBILITY sensor to help customers in the nonwoven industry with measuring air permeability. This is typically of interest in the field of nonwoven filtration media, such as HEPA filters or mouth masks. Contact Hammer-IMS for more information on this OEM sensor.

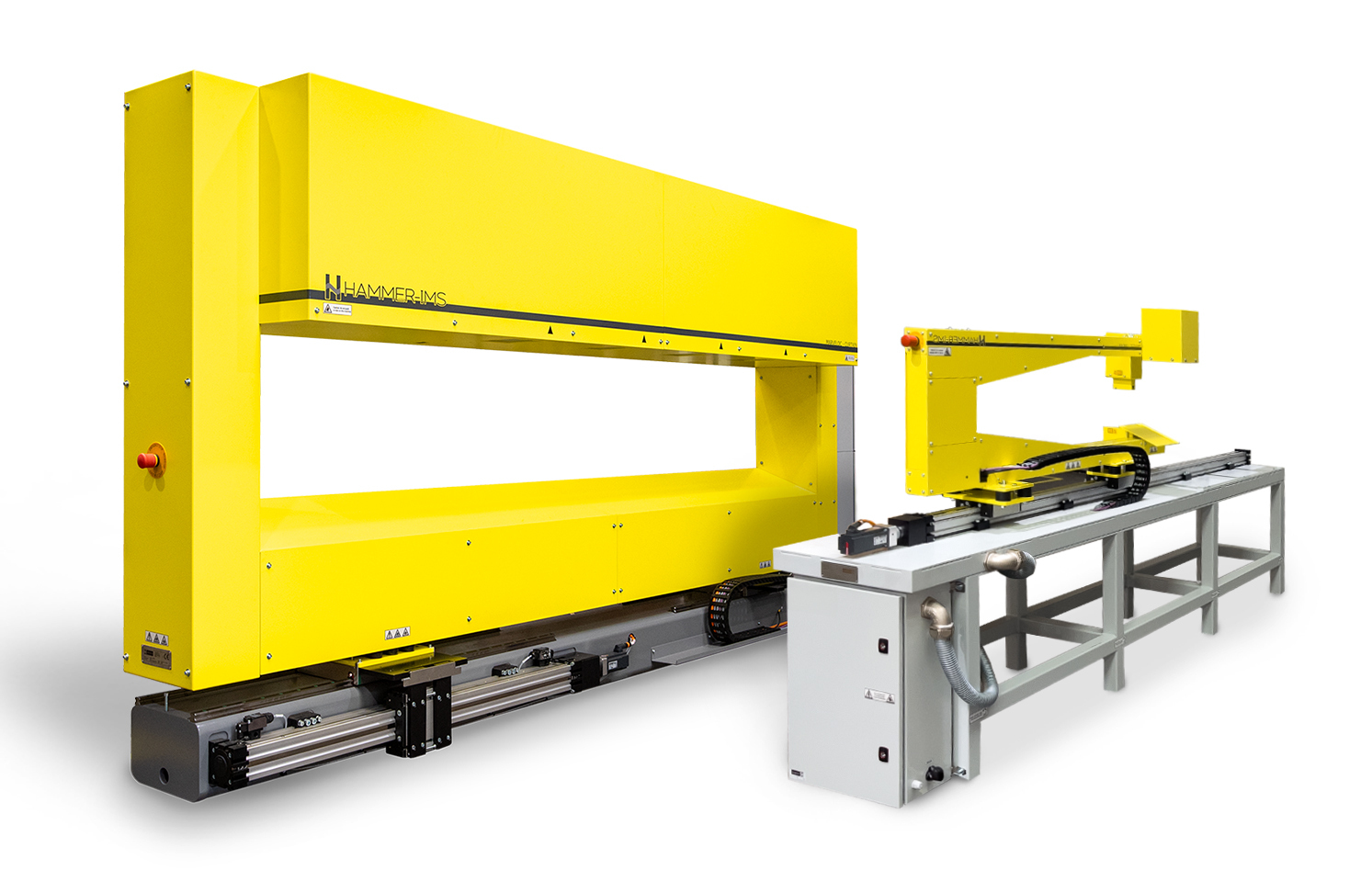

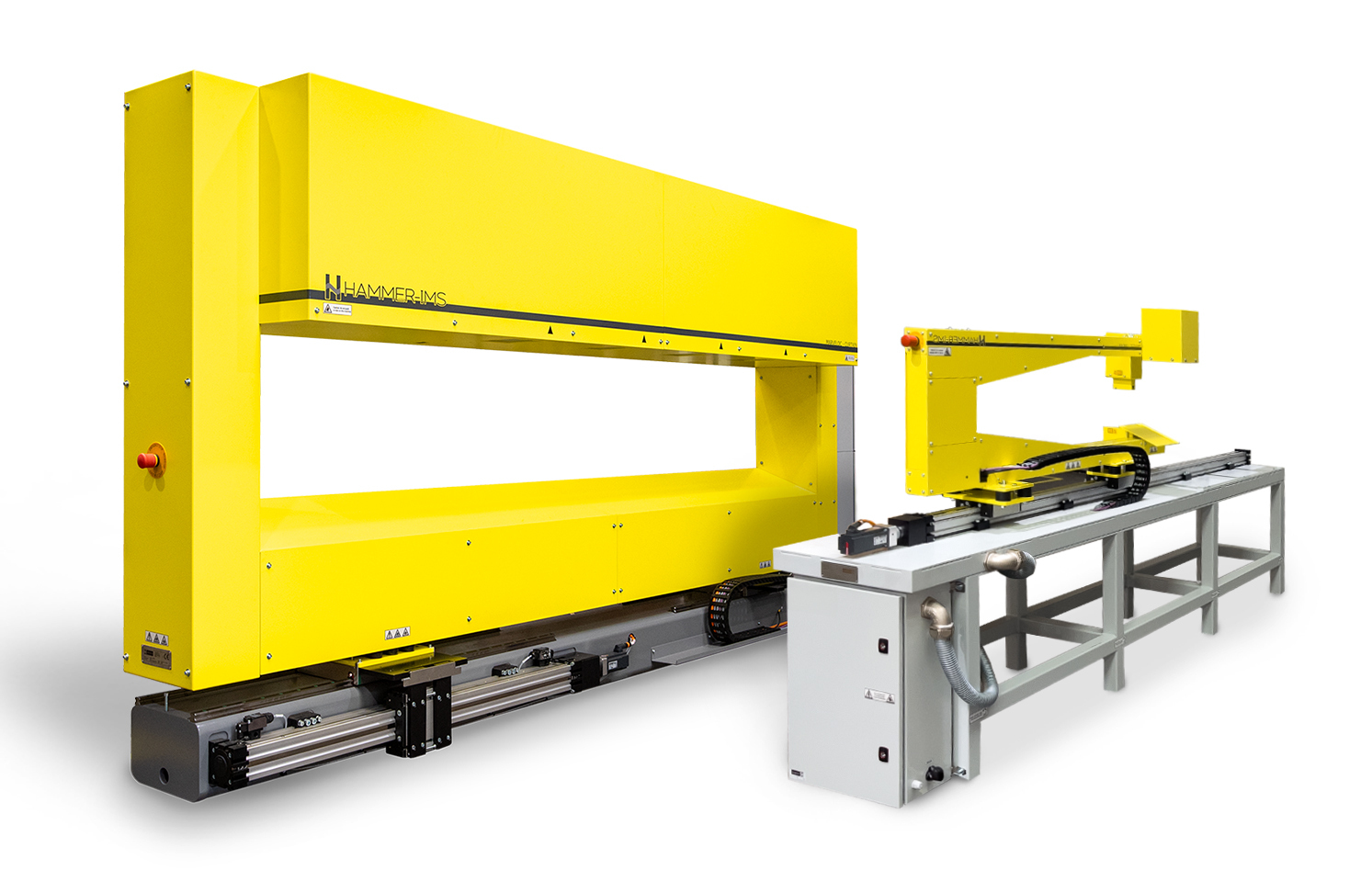

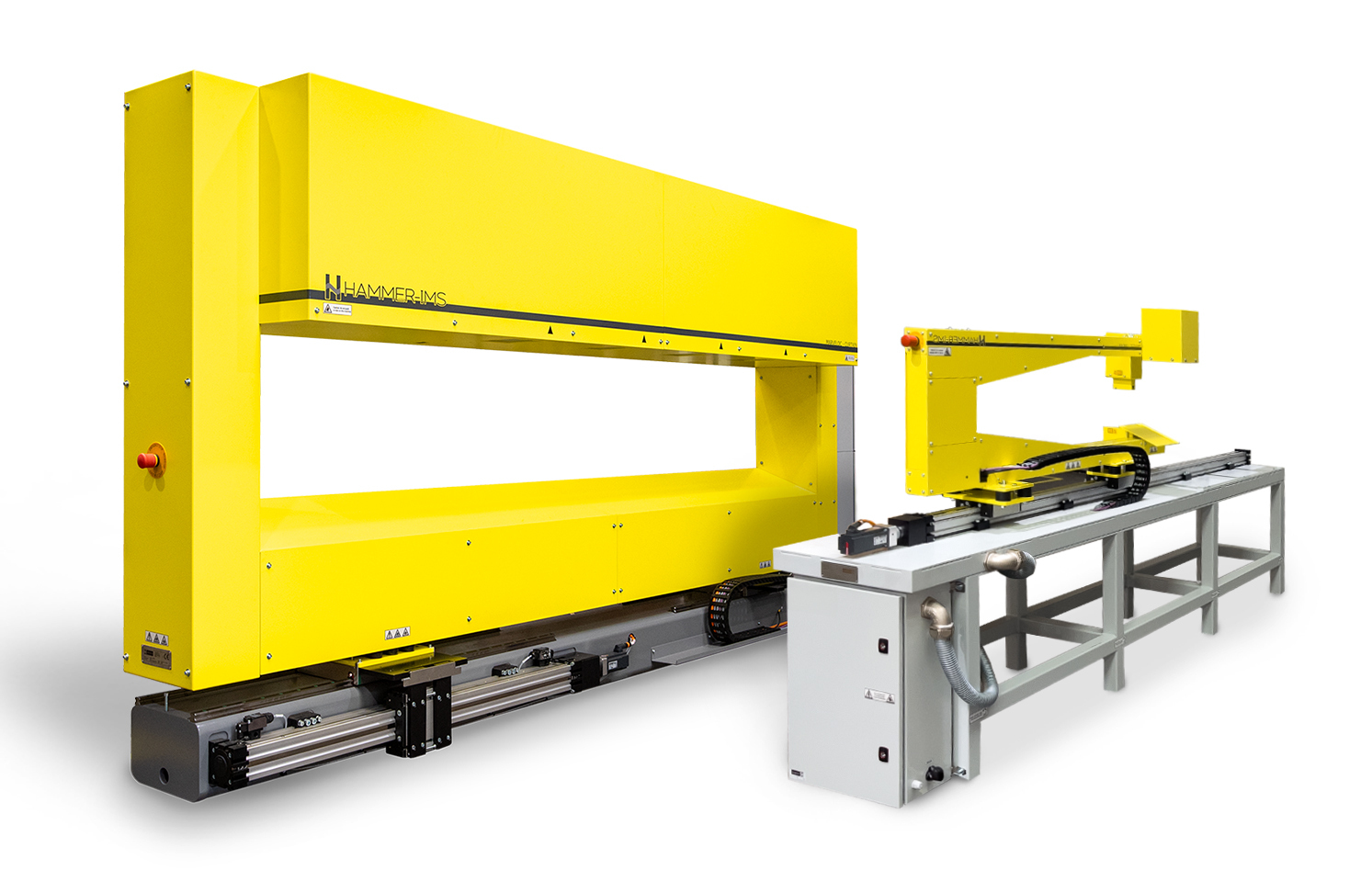

Inline quality control machines portfolio

Our machines have been developed to perform measurements 24/7 as part of an industrial production line. Scanners equipped with e.g. Marveloc thickness or weight measuring sensors which typically scan the production line in transversal direction, offering nearly 100% material coverage. Our scanning machines contain both traveling-frame and traveling-head scanners. Next to machines for inline use, Hammer-IMS offers machines for OEM and laboratory systems.

Our vision technology is mounted on stationary steel constructions. The concept of ‘scanning’ is arranged by analyzing video data in transversal direction from within our control software.

Regardless whether measurement or vision technology is applied, our robust machines are equipped with Hammer-IMS Connectivity 3.0 software for easy operation and intuitive visual reporting. On request, our installations can be connected to any process management software for centralized measurement data processing and storage.

The offering of Hammer-IMS machines contain the following machine variants:

- Marveloc-CURTAIN O-frame: robust system for wide production lines exceeding 2 meters

- Marveloc-CURTAIN C-frame: robust system with arm length up to 2 meters

- Marveloc-CHARIOT: compact and affordable single-head system

As an option, Hammer-IMS offers measuring solutions ready for use in potentially explosive (EX) environments (ATEX directive). When designing measuring machines for this purpose, our engineers take into account a range of specific aspects:

- Using anti-static materials at friction-critical machine parts

- Applying qualitative grounding wiring to all machine parts

- Carefully checking temperatures of critical machine parts

- Introducing overpressure systems and overpressure security mechanisms

Note that our M-Ray technology’s wireless output power is perfectly compatible with EX-environments.

Hammer-IMS optionally offers flexibly moving the system across R&D and production. In most cases, the measuring systems of Hammer-IMS serve a specific purpose at a fixed location. However, as an option, the machine can be adapted so that it can be readily moved using built-in castor wheels or on an external rail system. In addition to inline measurements, the measuring systems can be used for R&D tasks or offline material validation work. In these cases, transportability can be a special requirement. A transportable measuring system can deliver more value in inline settings since it can be applied to multiple production lines. A transportable measuring system can deliver more value in inline settings when it is applied to multiple production lines.

In support of R&D and offline material validation, Hammer-IMS offers an optional feeder unit for any of our CURTAIN or CHARIOT machines. Typically, a feeder transports sample materials through the measuring machine for R&D purposes or offline material validation. Feeders allow material samples to be fully covered and analyzed in great detail to maintain high product quality. The compact and lightweight feeder can be operated through the Hammer-IMS Connectivity software that controls the measuring system at the same time.

To run different measurement types simultaneously, Sensor Fusion allows different types of sensors to be installed in your CURTAIN or CHARIOT-based system. For example, Hammer-IMS could integrate laser technology in our Marveloc-CURTAIN scanners. While the sensor measures nonwoven basis-weight, a laser sensor continually tracks the material thickness. In addition, the laser line sensor continuously identifies the edge of the moving nonwoven produce using enhanced-precision material edge detection.

Connectivity software

The Marveloc featured products of Hammer-IMS are controlled through our Connectivity software. The software allows for controlling any Marveloc-CURTAIN system in a single software environment, regardless whether you are using a single-sensor or a multi-sensor system.

The software is easy to use, contains various industry-specific visualizations, and is available pre-installed on a rugged industrial PC or a desktop PC offering a widescreen experience. The software offers a number of both timestamped and position-based visualizations.

We support a wide range of industry-standard bus protocols. We support integrations based on Modbus TCP/IP, OPC UA or PROFINET for real-time links with existing industrial infrastructure. In this way, the data provided by our measuring systems can be used real-time by existing equipment to optimize the production process in real-time.

The Connectivity software offers single-click configuration according to the recipe that is currently being processed/produced by your machines. This straightforward approach avoids wasting precious time by eliminating repeated manual entry of entire production configurations for similar measurement jobs. It also prevents that human mistakes or improper configurations could inadvertently result in quality issues of your products. We are happy to assist you in converting existing recipe data file formats (Excel, csv, etc.) and upload these to your Hammer-IMS product to enable quick recipe startup.

The quality department can easily and flexibly obtain measurement data from our systems. Our rugged industrial computer platform has a front USB socket which can be configured for easy back up of any measurement data. This is practical for quality engineers to analyze measurement data in Microsoft Excel and draw conclusions on measurement data trends related to production quality and performance. It is also possible to obtain integrations with commercial database systems such as Microsoft SQL Server or data transfer over FTP.

The Connectivity software also supports the adjustment of extrusion dies, coating calenders and coating knives in closed loop. Measuring is key in controlling consistent material thickness or basis-weight. Ideally, a closed-loop feedback system provides the information to adjust the production process. As an option, Hammer-IMS can provide measurement data directly to automatic process controllers, or even implement the controller. Think about controlling the die in a plastic sheet extrusion line or controlling the calender or a coating knife for coated textiles. Such closed-loop feedback solutions respond quickly and operate automatically to systematically keep thickness or basis-weight within specifications.

Marveloc non-nuclear sensors family

Marveloc is our brand name for the sensor head modules embedding our thickness and basis-weight measuring technology. Marveloc stands for compatibility to the environment as well as robustness and scalability towards solutions containing multiple sensor heads.

Our Marveloc brand houses a number of different sensor sub-technologies as part of.

- M-Ray

Hammer-IMS incorporates its genuine M-Ray technology into its products. The origin of the technology lies in physics, with the so-called ‘millimeter waves’. Hammer-IMS has advanced and complemented these millimeter waves with state-of-the-art electronics, algorithms and mechanics to create the M-Ray technology. The high dynamics of Hammer-IMS M-Ray waves allow for high-precision thickness, basis-weight measurement or anomaly detection. The M-Ray technology has a broad application reach because the electromagnetic waves can penetrate through most non-metallic materials. The working principle of M-Ray-featured products of Hammer-IMS is straightforward: the longer it takes for the M-Rays to penetrate the material, the thicker or denser the material.

- C-Ray

Our C-Ray technology, as part of our Marveloc thickness and basis-weight measuring products, combines robust capacitive technology with integrated variable-standoff compensation. Thanks to the fact that Hammer-IMS has developed its own internal capacitive technology with its own sensor geometry, we are able to provide solutions that are either optimized for small measurement spot, precise measurement performance, increased measurement gap, or a combination of these. Our C-Ray technology allows for a minimal-effort integration into our CHARIOT scanner machines, making it extremely valuable for thickness measurement in thin-film plastics extrusion lines which are cost-sensitive and typically come with limited space availability next to the extrusion line.

- U-Ray

Our U-Ray technology is all about ultrasonics. Electromagnetic fields (C-Rays) or electromagnetic waves (M-Rays) do not penetrate metal or metallized objects. That is why for steel film or coated steel film, e.g. in the market of battery film, we help you out with our U-Ray technology. Hammer-IMS’s U-Rays use the same algorithms and calibration techniques as earlier introduced in our M-Rays technology, so we are able to provide you with stable measurement results. Note that our U-Rays are optimized for thinner materials.

- L-Ray

The L-Ray technology is based on one or more laser triangulation sensors. In a typical setup, the L-Ray sensor technology of Hammer-IMS applies two opposing laser sensors to measure the thickness of sheets or films in a differential way (one laser on top, one laser below). The choice of the specific sensor will be matched with the customer’s application: high-range versus high-precision, rough or shiny surface, etc.

Edge Vision connected multi-megapixel machine vision

The Edge Vision product family Hammer-IMS adds an additional eye on your product or process. We are offering these new products in the same industries which we are targeting with our inline thickness and basis-weight measuring solutions (both Marveloc-CURTAIN and Marveloc-CHARIOT products).

Focus is on applying vision in plastic film extrusion and textiles/nonwovens

hammerCurrently only available within our Reference Program, we offer the Edge Vision range of products in the markets of plastic film extrusion and textiles/nonwovens, providing solutions for:

- Black spot detection in extruded films and sheets

- Detection of length-direction stripes due to die contamination in extruded sheets

- Detection and quantification of color variations in nonwoven materials due to limited bale-opener or mixing randomness

- Detection and quantification of color variations in textile coatings or plastics extrusion due to improper blending

- 100% area weight measurement by light transmission