MCVE TECHNOLOGIE

Adresse

MCVE TECHNOLOGIE

86 rue Lieutenant Colonel Dagnaux

57685 Augny

Frankreich

Telefon+33 6 29 02 56 74

Entdecken Sie mehr von uns

Über uns

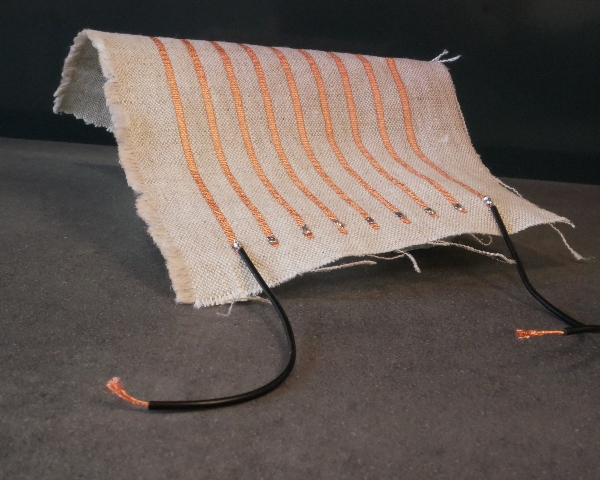

MCVE Technologie is an industrial solutions provider for printed electronics. We manufacture multifunctional fabrics that can be embedded in composite materials or others product. Their EOPROM® formulation enables the manufacturing of electrical copper circuits and electronic functions. The EopromFlex® process uses the screen printing deposition method as well as copper plating baths on flexible fabrics made of glass, polyester, polyamide or organosheet bio sourced. Copper is a familiar product for electronic people and is a strong raw material that allows a robust connection between the printed function and the electronics thanks to its solderability. MCVE’s technology is for mass production and we bring industrial cost down for embedded heaters, SHM (Structural Health Monitoring), or antenna application. Our EOPROM® paste provides excellent adhesion on different flexible fabrics glass fibers for smart composite manufacturing. The EOPROM® paste is a precursor to the metallization of plastics, so various metals can be deposited, in particular copper but also nickel, tin, silver and gold. MCVE’s solutions are ideal for composites, IoT, heating circuits, and medical applications.

FLAXTRONICS® - MCVE and bio-organosheet towards conformable electronics possibilities

Bio-organosheet PA 10-10 composite

Thermoplastic bio-organosheet set new standards and offer a wide range of applications in numerous industries. Bio-organosheet are high-performance, continuous fiber-reinforced composites made flax fabrics and bio-based resin.

Bio-organosheet basically consist of several layers of thermoplastic prepreg or semipreg material which are stacked and then pressed into a sheet with a thickness of up to 5 mm.

Thermoplastic organosheet sustainable product for the circular economy

These bio-organosheet can meet new requirements for sustainable designs.

For manufacturing bio-composites, this means using as few resources as possible and as little energy as possible in order to produce durable, sustainable products with a low carbon footprint

In fast processes such as thermocompression, bio-organosheet can be used to produce cost-effective components in large quantities.

Thermocompression offers several advantages:

- Fast cycle times: thermocompression takes only a few seconds to a few minutes

- Possibility for automation, which ensures consistent quality

- Recyclability of the material and scrap and thus the avoidance of large amounts of waste

- Direct forming into the final component through a single-stage process

Conformable Electronics by MCVE Technologie - 3D formed Circuits

EOPROM® technology is an additive manufacturing technology that delivers cost-effective, lightweight designs and provides a streamlined process for composite supply chain.

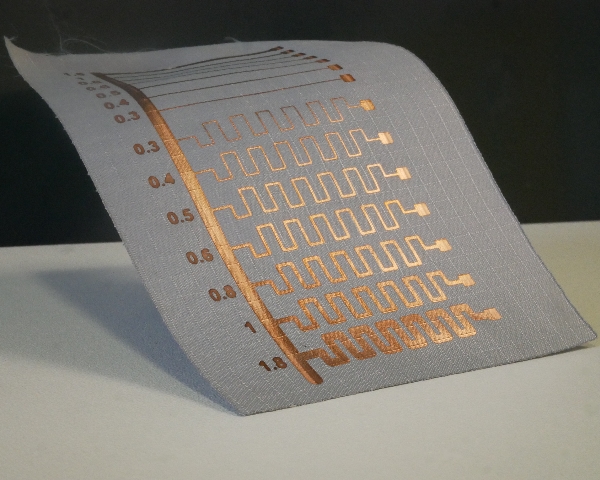

MCVE has already demonstrated a set of different functionalization with our EOPROM® technology, such as conductive tracks, sensors, or antennae, directly printed on glass textiles withstand standard composite manufacturing processes (resin infusion, curing at elevated temperatures).

MCVE has also demonstrated the functionalization with EOPROM® can withstand large deformation up to the failure of the composite. The integration of printed structures does not affect FRP mechanical performance. This can be explained by good chemical compatibility of the functionalization and the overall matrix of the FRP.

MCVE are qualifying EOPROM® process with large degrees of freedom for the design of integrated functions for different applications.

Conformable electronics

MCVE has already demonstrated with in house capabilities a POC showing the direct writing EOPROM® on organosheet glass fiber PA 10-10 .

The bio-organosheet with printed tracks and pads has successfully withstand the MCVE process with the thermocompression step ending up with a conformable electronics structure.

Also, we are proud to announce MCVE has validated conformable circuit made with EOPROM® technology with bio-organosheet flax fiber with biosourced resin PA10-10.

Tracks and busbar with Cu electrochemical deposit withstand the thermocompression step.

Establishing EOPROM® to fabricate conformable electronics

Today, MCVE has already proved our additive manufacturing technology delivers cost-effective, lightweight designs and provides a streamlined process in the composite industry.

MCVE is setting up a R2R production line without losing the process chemical, physical, and electrical characteristics to allow high-volume growth (Demand/Supply Management) to serve the industry demand.

MCVE will used the R2R process with thermoplastic organosheet which will bring added benefit.

Benefits will be increased product functionality, higher production performance, greater customization, shorter time to market.

Conformable electronics thermoplastic processing from prototyping to high-throughput mass production:

- Building the substrate, printing the conductive tracks with EOPROM®

- Pick-and-place the electronic components, interconnecting

- Thermocompression and overmoulding to achieve final product with electronics embedded.

Flaxtronics® Project – Industrial consortium

We are proud to announce MCVE is coordinator new consortium named Flaxtronics®.

Flaxtronics® means Plastronics which is a technology capable of improving the integration of electronic functions in or on polymer packages of electronic devices by implementation of conductive patterns and electronic components.

3D Plastronics technologies, is a fast-growing emerging manufacturing process for mass production of functional 3D devices. It is based on the screen printing of a thermoplastic flexible substrate (printed electronic process), followed by a 3D shaping using thermocompression .

Flaxtronics® is based on flax fabrics with bio-sourced resin PA 10-10 to meet new circular needs requirements for the circular economy. Flaxtronics® is based on bio-organosheet with copper tracks patterned with Eoprom® technology and then processed with thermocompression step to achieve a 3D bio-sourced smart device.

CONCLUSION

MCVE is paving the way to a new industry which will be fitted for mass production with bio-sourced products.

Our conformable electronics will bring free form, lightweight with a high degree of futuristic design.

Our cost effective R2R EopromFlex® production line will meet the high quality requirements for the mass production for integrated fabrication without disrupting the supply chain flow.

MCVE will offer our conformable electronics process, providing large degrees of freedom for integrating printed structures into bio-organosheet materials, thereby enabling the upscale of high-throughput mass production for conformable electronics.

Unsere Produktgruppen

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

- Functional Apparel Textiles

Unsere Anwendungsbereiche / Lösungen

Downloads

Dokumente

Keywords

- smart textile

- smart composite

- sustainable

- flexheater

- flexsensor

Unsere Produkte

Functionalisation of bio-sourced technical fabrics

Functionalisation of bio-sourced technical fabrics, such as flax combined with PA10-10 resin to manufacture a part by thermocompression dedicated for automotive application.

Copper-based electrical functions

Copper-based electrical functions are additively produced on coated or uncoated polyester technical fabrics. The fabric will remain flexible.

Printing heating tracks

Printing heating tracks, antennas and sensors on fibreglass reinforcement. The whole assembly is inserted into thermoplastic or thermosetting composites. The robustness of the composite structure is preserved.