Coated Yarn - sustainability

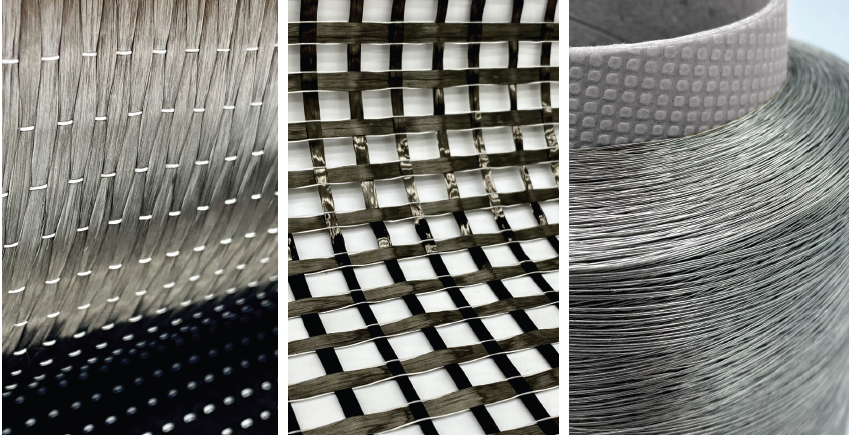

Description

All the while caring for the environment and trying to make our products as sustainable as possible, in addition to always being on the lookout for new ways to reduce the ecological footprint.

100% recyclable: TPU Evolution ® can be 100% recycled and give life to new products

Oekotex and Reach certified yarns

Solvent free: all our products are created without any solvent or toxic components

Water free technology: avant guard colouring process

Zero waste: the motto of our production process, perfected to the point of making full use of raw materials and eliminating waste.

Selection of polymers: based on varieties aiming at preserving natural resources

Ongoing research towards sustainability

Biodegradabilty related projects: developed with trusted institutions and partners, by use of soil - or sea biodegradable polymers