N. Schlumberger SAS

Adresse

N. Schlumberger SAS

240, Rue la République

68500 Guebwiller

France

Telefon+33 3 89 74 41 41

Fax+33 3 89 76 05 87

Entdecken Sie mehr von uns

Über uns

N.Schlumberger is the Manufacturer of textile machinery and complete fibre-to-yarn lines, N. Schlumberger is a global player in combing/recombing, spinning preparation, tow to top and semi-worsting of long staple fibres.

Present in more than 60 countries on every continent, N. Schlumberger is recognised around the world for its technological mastery of complete long-staple fibre lines. Its know-how allows it to guarantee its customers with solutions of the highest quality and best productivity.

Unsere Produktgruppen

- Fibres and Yarns

Unsere Anwendungsbereiche / Lösungen

Downloads

Dokumente

Keywords

- natural fibres

- technical fibres

- spinning lines

- man-made fibres

- long staple fibers

Unsere Produkte

Roving frame

BM21

For delicate material or material without cohesion like mohair, silk or flax, the BM21 roving frame is the solution. The BM21 is also used in the fancy yarn industry.

The BM21 roving frame for spinning preparation produces twisted rovings at speeds up to 120 m/min according to the material, the twist and the count. This corresponds to a maximal flyer speed of 1800 rpm.

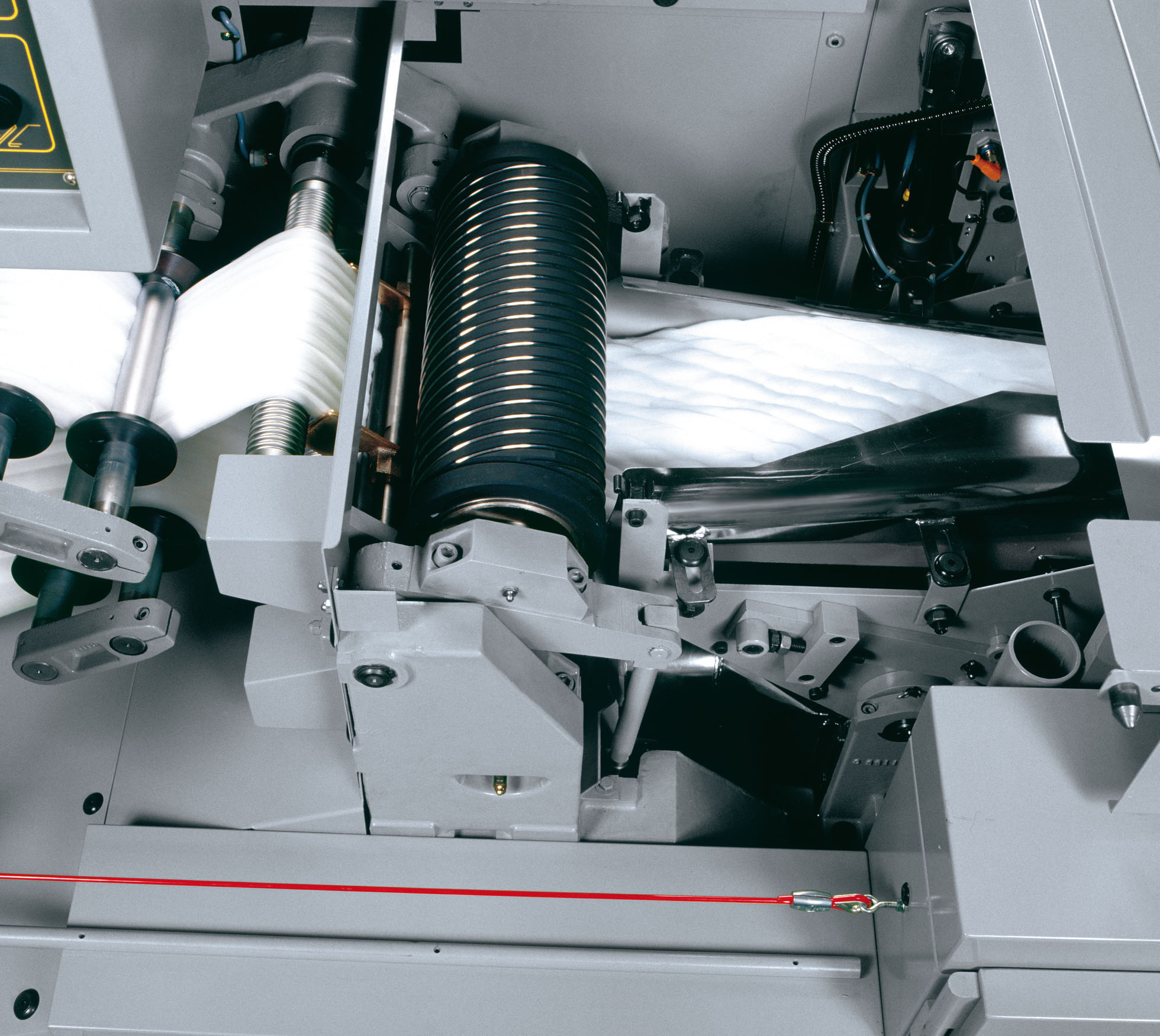

Built for high speeds with an absolutely precise bobbin built-up, the BM21 roving frame is fitted with a drafting system comprised of an apron and barrels.

These machines are available up to 64 spindles, in sections of 16 in a semi-automatic version.

Vertical rubbing frame

FMV50

The mechatronic vertical rubbing frame

The FMV50 is the evolution of the FMV40 with additional axis based on mechatronic technology which facilitate use and maintenance. Moreover the new 50 model is prepared to the Industry 4.0 with a complete data collection. The Internet connection allows machine diagnostic by our customer service.

The major interest of this mechatronic technology is to reduce mechanical settings and operators’ interventions. That is why many settings are electronically monitored in order to enhance precision and responsiveness.

Stretch breaking

Stretch breaking converting

n. schlumberger also developped a short stretch breaker especially designed for technical fibres. These fibres can be carbon fibres, glass fibres, metallic fibres, para or meta-aramids fibres, polyethylen (HMPE), polytetrafluoroethylen (PTFE) but also natural fibres like flax. All these fibres are used in composites parts thanks to their exceptionnal technical characteristics (high tenacity, elongation, stiffness etc.)

The FB20 model is used in a short in-line breaking process consisting of one pre-stretching block followed by three breaking heads.

Differents options are available according to the material processed. Due to many possibilities, please contact us for more information regarding your project.

Crush cutting converter

The TT12 converter is mainly for polyester (PES) but in some cases it also converts polyamide (PA) and polypropylene (PP).

This converting presents the following main advantages:

The fibres’ characteristics are maintained (crimp, resistance, lengthening)

The Hauteur diagram can easily be modified and reproduced easily

The percentages of short fibres and waste are very low.

The TT12 converter is fitted with a GC40 head and therefore benefits from the new chain gill ergonomics: better accessibility for servicing and maintenance.

Fitted with a crimping box at its delivery end, the TT12 produces a compact and resistant sliver, making it possible to increase its productivity as well as that of the next passage, and to process reputedly difficult fibres. Simple to use and safe, the TT12 converter represents the most advanced technology in terms of quality and the most efficient one from a production point of view

Long staple cards

Semi-worsted card

Suited to the processing of both natural and synthetic fibres. The semi-worsted card can be incorporated into any semi-worsted process line for carpet or knitting yarns.

Worsted card

Designed to process wool and other natural fibres such as mohair with two morels cylinders for the processing of scoured wool.

Flax card

This card is tailored to the process of flax tow and bast fibres. It is provided with a bale opener, especially suited to the bast fibres. This card is only available in 2.5 m working width.