L.G.L. Electronics S.p.A.

Adresse

L.G.L. Electronics S.p.A.

Via Ugo Foscolo 156

24024 Gandino Bergamo

Italien

Telefon+39 035 733408

Fax+39 035 733146

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

LGL Electronics was established in Gandino (Bergamo, Italy) in 1982 designing and manufacturing yarn accumulators for weaving machines.

Today LGL Electronics designs and produces a range tension control devices for weaving (Rapier, projectile and air jet looms), and for knitting (large diameter, seamless, socks and flat knitting) machines.

Unsere Produktgruppen

- Technology and Processes

Unsere Anwendungsbereiche / Lösungen

Downloads

Dokumente

Keywords

- yarn feeder

- weaving feeder

- tension control

- weaving

Unsere Produkte

Ecoprogress

Weft accumulators with separate adjustable coils that can be used on all gripper and projectile weaving machines.

- Automatic speed control

- Weft reserve control 100% dust, light and smear-proof

- Reversible Rotation Direction (S/Z)

- Compatible with either tradional or Canbus looms

- Automatic flywheel positioning upon yarn breakage

- Pattern preview mode

- Automatic loom stop

- Exclusion of broken wefts

Evolution

Weft pre-measuring winder for use on air-jet weaving machines.

- Allows a better weft stretching into the loom

- Reduction of broken and “slack” wefts in the fabric

- Pull-Back function

- Prevents interference between weft yarns left streaming out of the nozzle after cutting back in and other weft yarns about to be inserted

- Can be installed afterwards

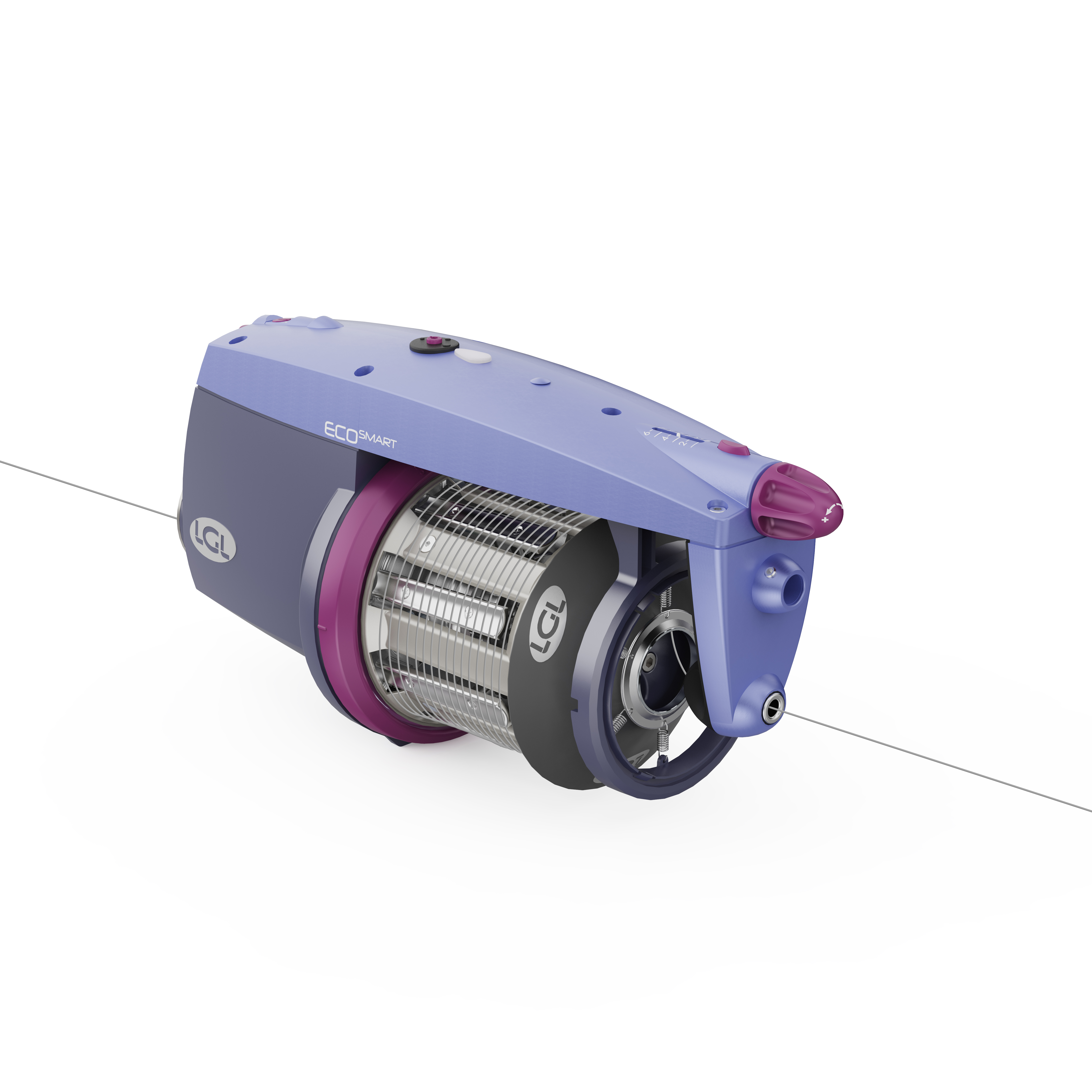

Ecosmart

Weft accumulators with separate adjustable coils that can be used on all gripper and projectile weaving machines.

- Automatic speed control

- Weft reserve control 100% dust, light and smear-proof

- Reversible Rotation Direction (S/Z)

- Compatible with either tradional or Canbus looms

- Automatic flywheel positioning upon yarn breakage

- Pattern preview mode

- Automatic loom stop

- Exclusion of broken wefts

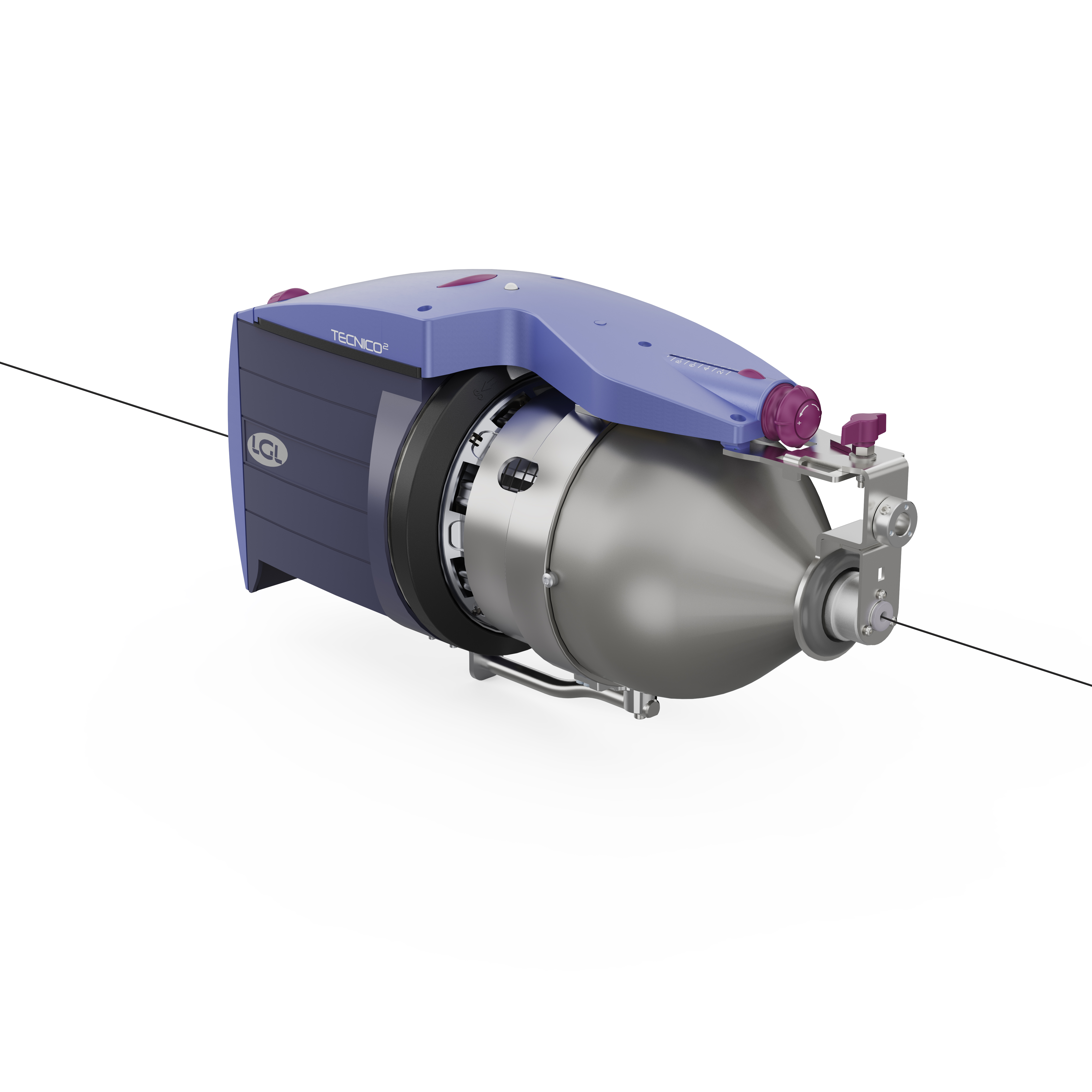

Tecnico

Weft accumulator with separate adjustable coils that can be used on all gripper and projectile weaving machines. It is equipped with specific solutions aimed at weaving technical wefts such as polypropylene strap, jute and aggressive yarns, fibreglass, rowing, monofilament yarns.

- Automatic speed control

- Weft reserve control 100% dust, light and smear-proof

- Reversible Rotation Direction (S/Z)

- Compatible with either tradional or Canbus looms

- 10 mm internal yarn channel

- Drum designed to reduce yarn stress

- Adjustable responsiveness to suit different yarn being woven

- Automatic loom stop

- Exclusion of broken wefts

Multiple versions available

Each of those equipped with technical solution designed to deliver best weaving performance for each weft:

• Carbon fiber

• Polypropylene

• Fiberglass

• Jute

• Monofilament

• Kevlar

• Rowing

• Steel wire