Lenzing Instruments GmbH & Co. KG

ELKOMETER

Zum Produkt

LISTER AUTO

Zum Produkt

ELKOMETER

Zum Produkt

LISTER AUTO

Zum Produkt

ELKOMETER

Zum Produkt

LISTER AUTO

Zum ProduktAdresse

Lenzing Instruments GmbH & Co. KG

Technologiepark 4

4851 Gampern

Austria

Telefon+43 7682 93030902

Fax+43 7682 93030911

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

The Austrian company Lenzing Instruments GmbH & KG, member of the Textechno Group, is a worldwide renowned producer of advanced equipment for quality- and process control of filament yarn, staple fiber, nonwovens and plastic film.

For more than 50 years, Lenzing Instruments is a major player within the field of testing.

The initial experience gathered during the development and production of quality proof instruments for Lenzing AG - a leading producer of staple fiber, nonwovens, plastic films and paper - was gradually adapted and integrated also in the quality proof systems of external companies.

As a result of continuous in-house development and scientific exchange with external technology partners, new testing instruments were constantly implemented in the product range and Lenzing Instruments now offers a wide array of products.

With the development of standard setting testing equipment, Lenzing Instruments has been involved in the definition of internationally approved testing standards. The product range reaches from standardised laboratory equipment to individual solutions.

Lenzing Instruments focuses on customer orientation.

Apart from standard testing equipment, quality control systems are also developed according to the specific needs of each customer. This applies for instance to the offered online systems for continuous process control, which are set up according to specific and individual demands.

The continuous innovation process and the rising demand for online control systems make Lenzing Instruments to one of the leading suppliers of individual customer solutions in that field.

At Lenzing Instruments, priority is given to innovation and customer service The optimal customer support is guaranteed through a worldwide sales- and service network.

Online filament testing:

- Lenzing Instruments offers a variety of online sensors for real time monitoring of filament yarn and detection of yarn diameter variations, interlace, twist, tension, spin finish, colour as well as all kinds of yarn defects such as broken filaments and fluff.

- Combined sensor and camera systems offer online and offline (laboratory) image analysis of detected yarn defects.

Online staple fiber testing:

- CIS 300, for continuous and real time control number of crimp and crimp distribution

Online nonwovens testing:

- NIS 300, for continuous and real time control of physical and aesthetical defects of the web

- NOS 300 for online control of the fiber orientation in means of the ratio between fibers in machine versus cross direction

Online fabric and composite materials testing:

- INVISPEC for online process control of defects on all kinds of materials

At-line and laboratory filament testing:

- DTI 600 measures the draw tension and draw elongation of the filament on the running yarn

- ACW 600/DVA determines the denier and the denier variation of the yarn

- RAPID 600 V for interlaced yarn gives information about the number of nodes, their regularity and strength

- SESS is an end sampling system for the coordinated, automated testing procedure of the three above mentioned instruments

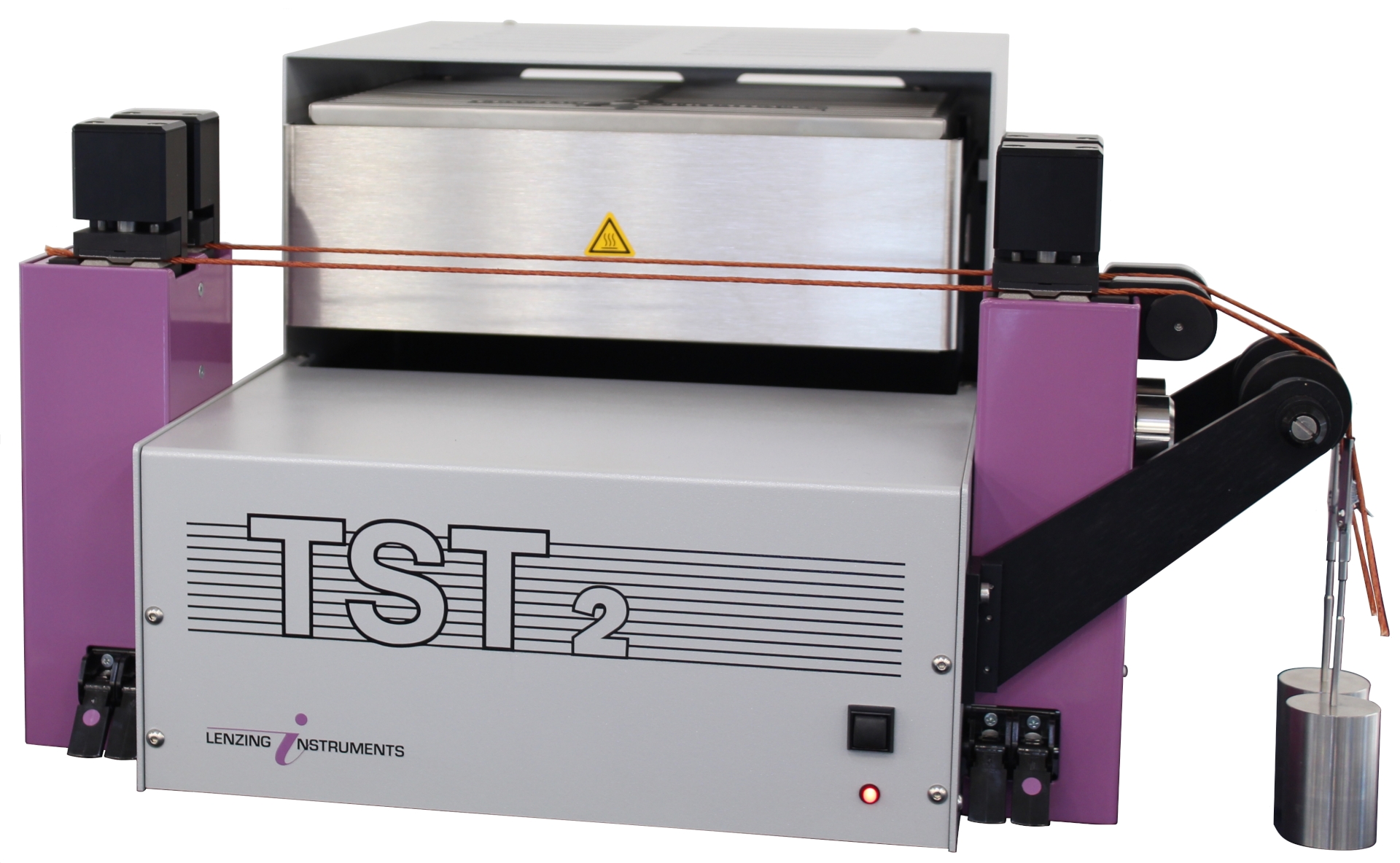

- TST 510/250 TST 2 for automatic and accurate determination of percent shrinkage and shrinkage force of either 10 or 2 samples in one test run

- ALFA 500 / ALFA NMR determination of the spin finish content (FOY/OPU)

- ELKOMETER high-volume defect detection on the running yarn.

Laboratory nonwovens testing:

- LISTER AC determines the water permeability in terms of liquid strike through time of nonwoven cover stock

- WETBACK for determination of the rewet properties of nonwoven cover stock

- RUNOFF tester for evaluation of the run-off characteristics of nonwovens

- GE-TE-FLOW measures the water permeability of geotextiles and related materials

- SLOSH BOX 100 is a dispersibility tester for determination of the flushability of nonwoven materials

- GT 1200 for determination of the characteristic opening size of geotextiles and geotextile-related products

In addition to the above mentioned testing systems, Lenzing Instruments also offers further equipment for filament and nonwovens testing as well as a spectrum of products for testing of staple fibers and plastic film.

Unsere Produktgruppen

Unsere Anwendungsbereiche / Lösungen

Keywords

- quality control

- inspection

- online

- testing

- laboratory

Unsere Produkte

TST 2

TST 2 shows the way when it comes to thermal shrinkage testing of filament yarn such as tyre cord. The tabletop device offers versatile testing of up to two samples for either shrinkage % or shrinkage force or both in one and the same test run.

Users all over the world appreciate the flexible operation and the vast evaluation possibilities of the TST software. The Thermal Shrinkage Tester is also available as TST 510/250 for testing of up to 10 yarn samples simultaneously, or as TST 1 for thermal shrinkage testing of one wider sample such as synthetic film of up to 50 mm width.

OPUMETER

OPUMETER is a handheld instrument, which is used to measure the spin finish content as OPU% directly on the running yarn after the spin finish nozzle. It may be used for POY and FDY and for any conductive spin finish composition. The yarn just has to be held between the ceramic pins of the instrument for some seconds in order to yield a real-time value of the present spin finish concentration. It is a relative measurement, referring to the conductivity of the spin finish on the passing yarn.

By means of this method, also short term deviations of the spin finish level due to air bubbles, faulty pumps or applicators may be detected and reacted to without any delay. OPUMETER offers a high degree of flexibility, both when it comes to location of use and results evaluation - it may be used at different production machines within short time. That way, it enables quick reactions to process malfunctions, with cost savings as a result.

ELKOMETER

Lenzing Instruments' ELKOMETER 200 provides yarn producers and converters with a high-volume precision tool for off-line defect detection. A powerful yarn take-off unit guides up to eight parallel positioned yarn samples through PROMPT OLO online sensors. Defects such as thin- and thick places, broken filaments and fluff are detected and reported in terms of quantity and position. If an in-depth defect analysis is requested, images of each detected defect can be generated by means of the optional DEFECT VIEW camera system, which is installed at one of the positions. Additionally to the pure inspection mode, a special defect assessment mode enables human inspection by stopping the system after each detected defect.

LISTER AUTO

For decades, LISTER AC by Lenzing Instruments is the trusted choice for measuring the time for a known volume of liquid to pass through a nonwoven material, i.e. the liquid strike-through time. The test procedure conforms fully with INDA/EDANA standards WSP 70.3 and 70.7 and highest reproducibility and comparability are guaranteed for. However, some applications require frequent testing, leading to resource and cost constraints. With the time- and resource saving newcomer LISTER AUTO, users are offered an automatic alternative for the liquid strike-through test: A turn table with five sample positions successively presents the nonwoven material to an integrated LISTER unit. A timer guarantees for accurate and unbiased results also in case the repeated LISTER test mode is selected. LISTER AUTO provides a flexible and efficient solution while retaining the benefits of the Lister AC.

RAPID 600 V

The quality of interlaced yarns depends on node count, regularity, and tenacity of the nodes; crucial for downstream processes such as weaving and knitting. RAPID 600 V offers automated and servo-controlled pretensioning, string-up and sample removal for faster, more accurate testing of entangled filament yarns. Using a vertically moving pin, it detects entangled nodes, determining their count, distance, and tenacity per ASTM D4724. The mechanical pin system ensures only nodes meeting operator-defined tension are accepted. Designed robustly, it is not confined to laboratories, but can be used near production lines for early testing. This facilitates quicker evaluation of interlace quality and prompt reaction to irregularities. With total computer control and user-friendly handling, RAPID 600 V streamlines testing, leading to significant labor savings. An even higher automation degree can be achieved with RAPID 600 V in combination with SESS, Lenzing Instruments' Sequential End Sampling System for automatic and successive measurement of a customer-specified number of bobbins, directly off the transport buggy.