Klieverik

Über uns

Klieverik is a dynamic company, focused on rotary thermo-processing equipment for advanced textiles. With more than 40 years of experience we design, manufacture, install and maintain innovative industrial machinery. We manufacture stand-alone equipment and complete product lines. Our highly versatile machinery provides added value and improves the efficiency of textile printing and finishing operations. Klieverik is based in Oldenzaal. The Netherlands, where we design and build our machinery. Our calenders are shipped, installed and serviced world wide.

We offer solutions with rotary thermo-processing systems, also called heat presses or dwell calenders for:

- Dye sublimation printing and dye fixation (digital/analog printing)

- Laminating and coating of (technical) textiles

- Thermobonding of non-woven

- Production lines for thermoplastic composite prepregs

- Fusing and laminating of carpet

Unsere Produktgruppen

- Technology and Processes

- Bondtec (Surface & Bonding Techniques)

Unsere Anwendungsbereiche / Lösungen

Keywords

- coating

- thermo-adhesive powder

- laminating

- thermobonding

- calender

Unsere Produkte

LFC Coating Calender

Klieverik Coating Technology offers a versatile solution for applying thermo-adhesives, enabling the enhancement of substrate functionality, the creation of innovative products, or the integration of adhesives for subsequent activation in the production process. Whether utilized for roll-to-roll lamination or in a heated press for cut-pieces, this technology facilitates efficient and precise coating applications, ensuring optimal performance and product quality.

Features

- Working widths up to 5800 mm/ 228 inch

- Speed up to 80 m/min/ 262 ft/min

- Drum sizes 500–1800 mm/ 20-71 inch

- Electrically heated or by secondary oil circuit from external boiler house

- Additional pressure rollers possible

- Siliconised Nomex belt

- Drum covered with Teflon sheets or coating

CFC Carpet Fusing Calender

The Klieverik Carpet fusing calender for latex-free carpets. Klieverik has developed and engineered its Carpet Fusing Calender (CFC)® with state of the art technology and with environmental concern in mind. The CFC stand-alone is able to replace a latex production line for pre-coating of carpets. By heating, the CFC® ensures a tuft-lock / fiber bonding over the complete working width. As a result of this bonding effect, the traditional latex pre-coat can be completely eliminated and the bonded carpet can still pass al regular testing methods. Together with the limited required energy, this results in a significant lower production cost.

Some features of the CFC®

- user friendly operating system with state of the art storage of process parameters

- equal temperature withing 1°C over the total width

- working width can be easily adjusted

- synchronised PLC control over dwelling time during production at any speed

- calibrating pressure roller

- heavy duty construction

Roller and working with of CFC®

- working width 2500 – 5500 mm

- roller width 2750 – 6000 mm

- diameter heating drum 1350mm

- mechanical speed 1-30m/min

Klieverik R&D Center

Klieverik R&D Center. Are you intrigued by the possibilities of our calenders? Would you like to get a better understanding of our technology? We invite you to visit us in Oldenzaal, The Netherlands where we can show your the Klieverik equipment in person at our R&D Center.

Our intent is to demonstrate a proof of concept with your materials or we can offer you a wide range of our own materials which are available in our R&D Center. We also provide a wide range of thermoplastic adhesives from global suppliers in the form of films, webs and powders. There are no charges involved with this testing so there is nothing to lose, only to gain.

You could also rent our R&D Center for optimizing your test results or for preparing samples of qualification of the materials for your customer.

Ecosafe

Ecosafe

We have developed a special execution of the laminating calender with a modified web path: The Ecosafe calender. The Ecosafe is suitable for thick substrates, substrates that are sensitive to heat or pressure and/or high speed lamination. The Ecosafe concept combines adhesive application at high speed and minimal use of energy with the subsequent laminating of the second substrate outside the calender. The Ecosafe can operate with any type of thermoplastic adhesive powder, film or web and creates a very versatile and highly productive line.

Features

- Cost effective due to high speed, minimal consumption of energy and adhesive

- Versatile in usage; use with or without Ecosafe extension

- Ecosafe web path makes all types of lamination materials possible even ridged materials

- Eco friendly alternative to flame bonding: no toxic fumes, untreated and thus lower cost foam can be processed.

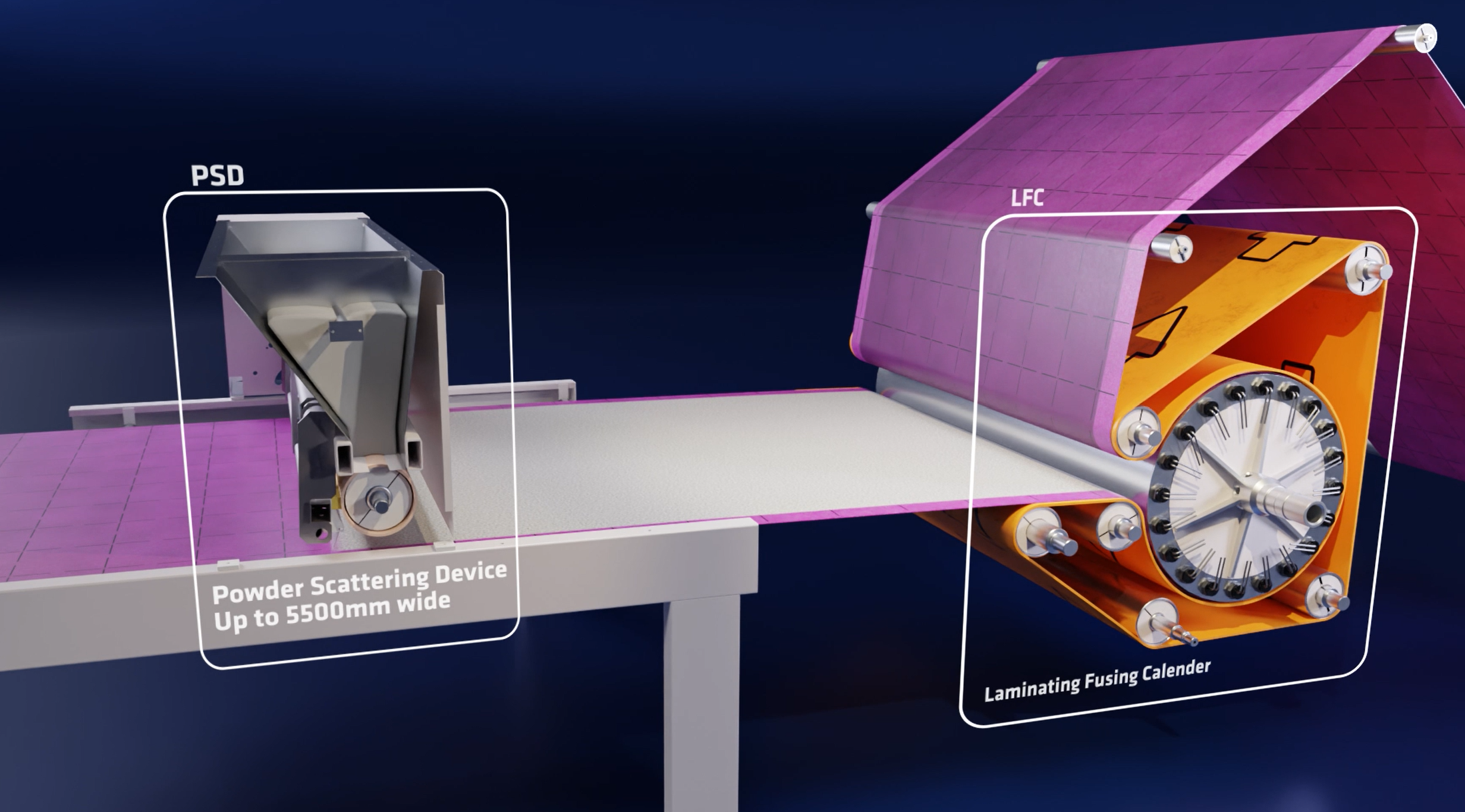

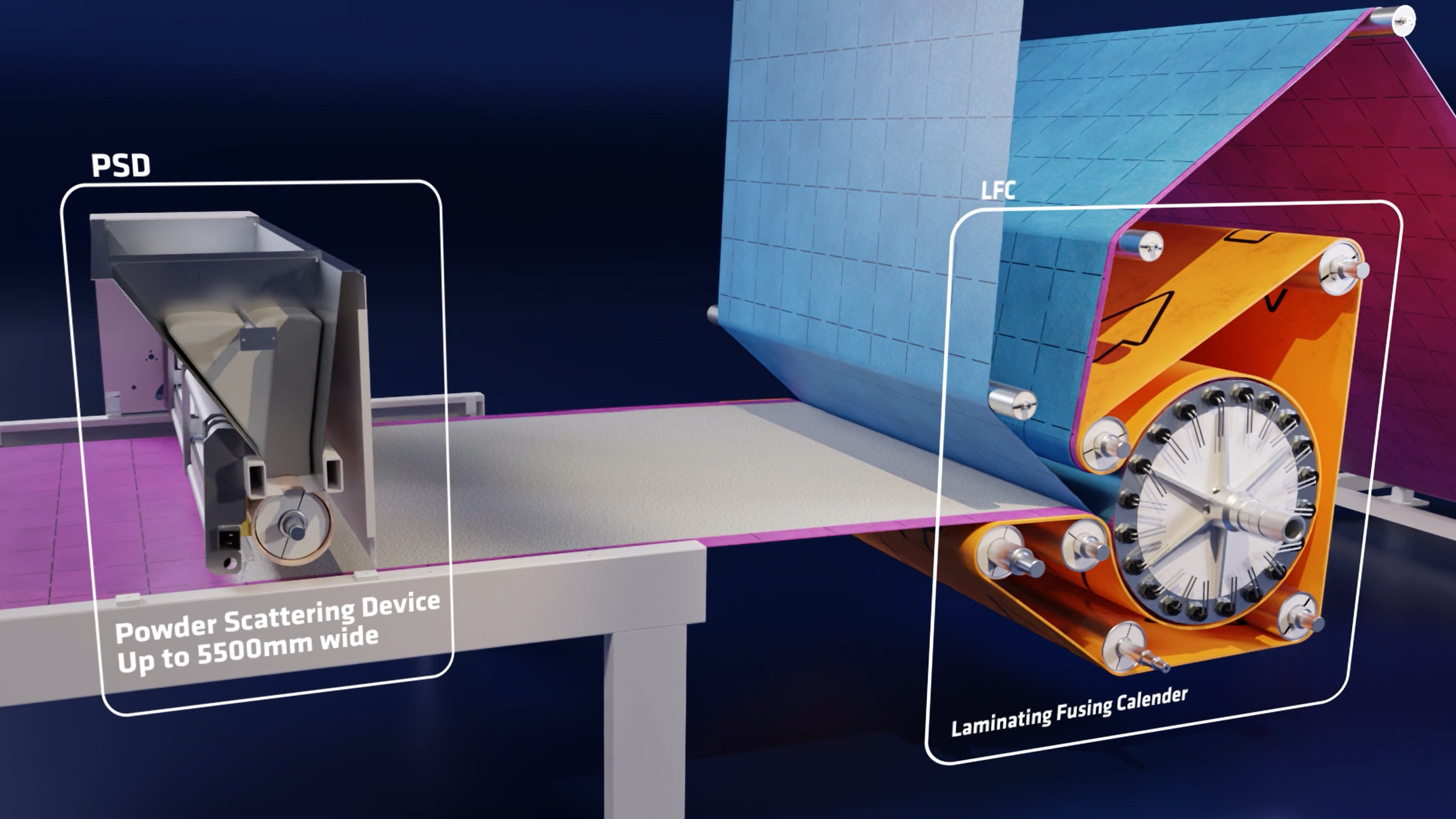

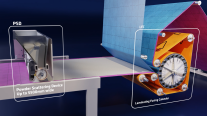

LFC Laminating Fusing Calender

Klieverik Laminating Technology offers versatile solutions for laminating processes using thermoplastic adhesive materials.

For laminating with thermoplastic adhesive powder, a Powder Scattering Device (PSD) evenly disperses the adhesive over the material. An optional infrared pre-heater can be employed to enhance adhesion. The subsequent step involves heating and pressing the materials together with an adjustable pressure roller.

Alternatively, laminating with thermoplastic adhesive film or web eliminates the need for a powder scattering device. Instead, fil/web unwinder is used to hold the film or web, which is inserted between the layers of material. The laminating calender then applies adjustable heat and pressure for optimal bonding.

Features

- Working widths up to 5800 mm/ 228 inch

- Speed up to 80 m/min/ 262 ft/min

- Drum sizes 500–1800 mm/ 20-71 inch

- Electrically heated or by secondary oil circuit from external boiler house

- Additional pressure rollers possible

- Siliconised Nomex belt

- Drum covered with Teflon sheets or coating