Twistechnology®

Adresse

Twistechnology®

Ctra Montcada 584, 1

08223 Terrassa

Spanien

Telefon+34 937 89 41 00

Fax+34 937 89 43 55

Entdecken Sie mehr von uns

Über uns

RING DOUBLING AND TWISTING MACHINES AND COATING

Twistechnology® with a long textile history that started in Terrassa (Barcelona-Spain) is exported in more than 98% of its production and installed in more than 65 countries.

Friendly machine philosophy

* Machines adapted to each and every customer’s requirements.

Our aim is to give you solutions for your twisting process. And recently your coating needs.

* The simplicity of its use.

Extreme simplicity of use, all changes are made through a screen keyboard, without any need to change any mechanism or gearing. Production data is stored for easy repetition. Machines are prepared to be controlled via PC and/or modem

* The low maintenance.

Our machines are designed to reduce time and cost maintenance. We have always been specialized in making very robust, simply designed machinery. All sections have been carefully developed to be easy to operate and to avoid damage by intensive use

* Its standard components.

Standard components, to give you the freedom to buy spare parts in any part of the world, with the consequent saving in time and costs. Most of our machine components are standard pieces on the market made by the best international manufacturers.

Engineering Department

We are used to participate in our customer’s projects giving them support as an engineering consultant and our experience and know how in this field makes our recommendations very valuable.

Hand-Key Projects

Twistechnology® designs complete and personalized projects for each customer depending on their industry or field, we coordinate all the steps from the study and design of the project to the set up of it and also giving technical support after it is completely in operation in customer’s facilities.

Training and test LAB

Laboratory test in Twistechnology® to make trials with your own yarn. The company uses in-house technology and patents to promote research and technological innovation. Leader in innovative twisting solutions.

Technical Support Department

Support for any technical doubt, problem or new need at any time. Our technical department is always at your service. This service is also in charge of spare parts inquiries.

Experience and innovation makes us your best partner to improve your twisting and coating needs.

Unsere Produktgruppen

- Technology and Processes

Unsere Anwendungsbereiche / Lösungen

Keywords

- Twisting

- Coating

- Winding

- Ring

- Plying

Unsere Produkte

TWISTEC-TANDEM

Twisting machines for small productions or producing a wide range of different products.

Our range of monoblock machines configured as follows:

TWISTEC – One block machine that can be designed from 3 to 8 spindles depending on the ring size.

TANDEM– Two block machine that can be designed from 8 to 16 spindles depending on the ring size.

TWISTEC 3– One block machine that can be designed from 9 to 24 spindles depending on the ring size.

Also, TWISTECHNOLOGY manufactures special designed machines for laboratory like:

TWISTEC DUO – Two spindle machine, smaller structure as usual Twistec.

TWISTEC UNO– One spindle machine, smaller structure as usual Twistec.

- Economic flexible production.

- Machine can produce the same product in all spindles or one different product in each spindle.

- Production data stored for 99 different products.

- Specially designed to take care of technical and delicate yarns.

- Twist quality: Automatic self control and adjustment system. – Max. speed: 200m/min.

- Different package shapes can be configured: Cylindrical, Biconical ,Textile Bottle Conical Bottle and Textile wrap

- Range of diameter and height of rings can be installed

TWISTFIX LINE (COATING, DRYING AND WINDING)

IN-LINE SYSTEMS

The TWISTFIX range of MODULAR machines are designed to impregnate, to dry, to spread and to wind filaments, yarns, fine cords,

tapes or bands. The machine can be adapted to any particular feature that the customer may need. We can distinguish five process

steps with different possibilities.

UNWINDING

- CREEL pulled from the top with yarn guide and small tension device.

- UNWINDER (for spreading only) feed roller rolled off from a bobbin.

IMPREGNATION:

By immersion tank:

· With manual adjustable to get more or less impregnation.

· A pump transfers the solution from a main tank (any container that the customer may already have) and keeps the solution

level constant.

By kiss-roll:

· Two driven rollers transfer solution from the tank as it turns. The material is pressed against the top part of the rollers and

is impregnated.

SPREADING

· The filaments in the tow are spread.

DRYING:

· Drying tunnel with infrared lamps.

· Tunnel with forced hot air.

· Different lengths for the tunnel are available.

TAKE UP

· Winding: several independent heads of winder.

· Twisting: connection to ring twisting machine with different plies.

· Tape winding: after spreading the tow wound as a tape.

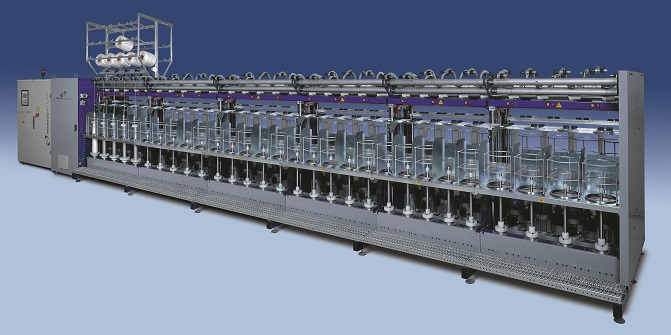

TWISPEED

Twisting machines for large production of thin and medium yarns.

Main features:

- 2 independent sides (2 machines in 1).

- Prepared to connection to PC.

- Twist quality: Automatic self control and adjustment system.

- Production data stored for 99 different products.

- Max. speed: 120m/min.

- Different package shapes can be configured: Cylindrical, Biconical ,Textile Bottle Conical Bottle and Textile wrap

- Range of diameter and height of rings can be installed

TWISTHOLE

Monoblock machine for technical yarns

Machine specially designed to work technical yarns allowing:

Increasing production up to 40 % and more

• High quality results

• Lower working tension

• Increasing range of twisting at very lower tex (1 tex)

• Individual transmission by motor-spindle. Patented system.

• Individual counter meter in each spindle. Stop individually at preselected number of meters.

• Designed in 1, 2 or 3 modules like Twistec-Tandem line.

TWISTGLASS

Twisting machine specially designed for fiber glass yarn.

Main features:

- Cake is driven by individual motor.

- Independent standard motor connected to the spindle group.

- Computer parameters are prepared to be easily adapted to customer specifications.

- Standard spare parts (save time and money).

- Long life for motors.

- Resistant cake pincers.

- Controlled movement for accurate bobbins.

- Special package shapes for the cake and the final package