friedola 1888 GmbH

Über uns

Our company goes back all the way to 1888 and is one of the leading quality providers of synthetic-based interior and exterior furnishings for numerous areas of technical application. With both of our production sites in Meinhard-Frieda and Osterode, we represent extremely diverse manufacturing processes, made in Germany.

As an innovative manufacturer of technical films, foamed and coated carrier materials, as well as technical knitted goods, we predominantly offer customer-individualized and tailored product, furnishing, and fabrication solutions.

Our high-performing sales and development team is happy to work with you on integrated solutions for precisely defined applications and functions.

Unsere Produktgruppen

- Woven Fabrics, Laid Webs, Braidings, Knitted Fabrics

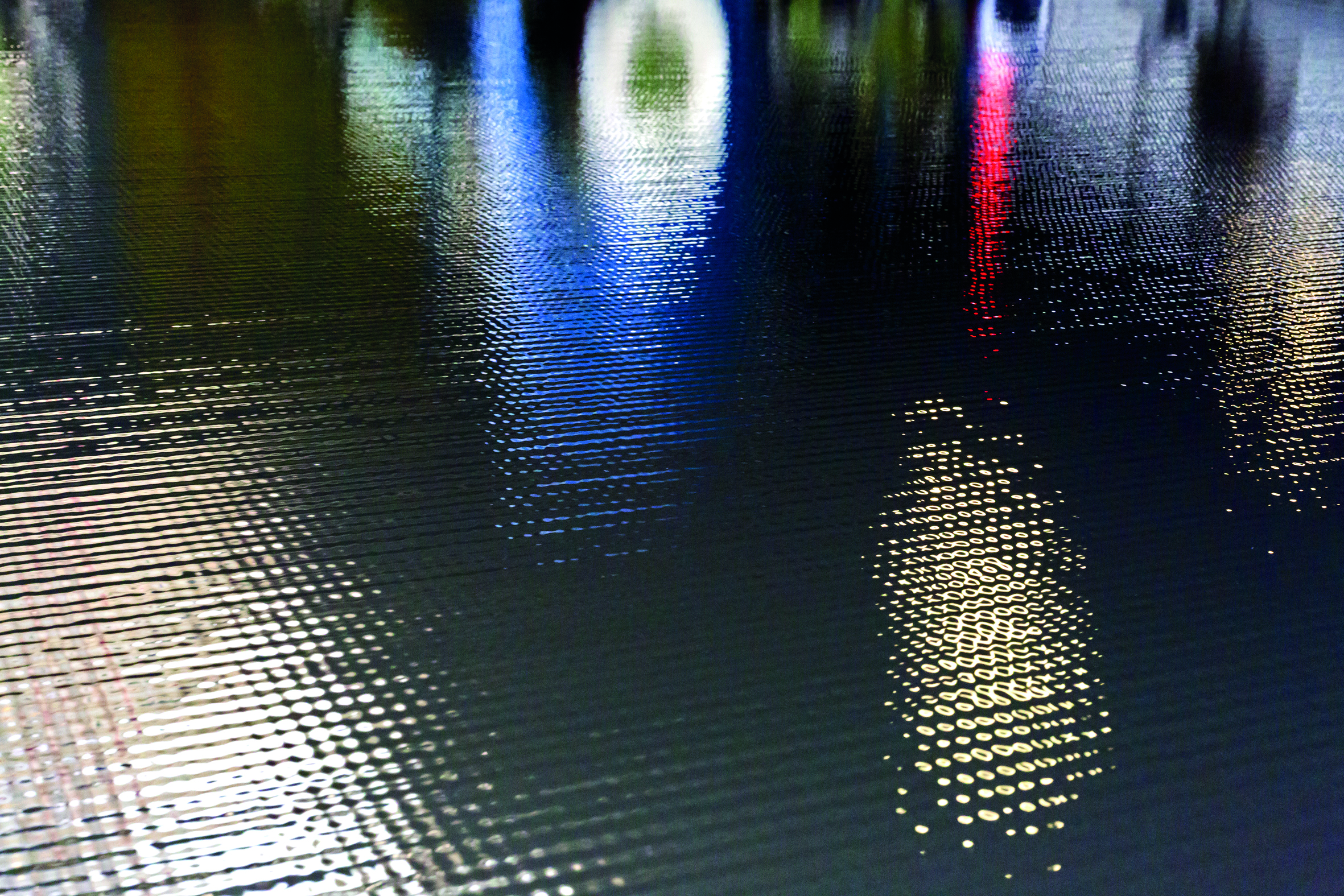

- Coated Textiles

Unsere Anwendungsbereiche / Lösungen

Keywords

- Folienextrusion / Kalanderbeschichtung

- Textilbeschichtung / Schäumen

- Oberflächen-Finish

- Textile Flächenerzeugung

- Kompetenzcenter Entwicklungs- und Pilotanlagen

Unsere Produkte

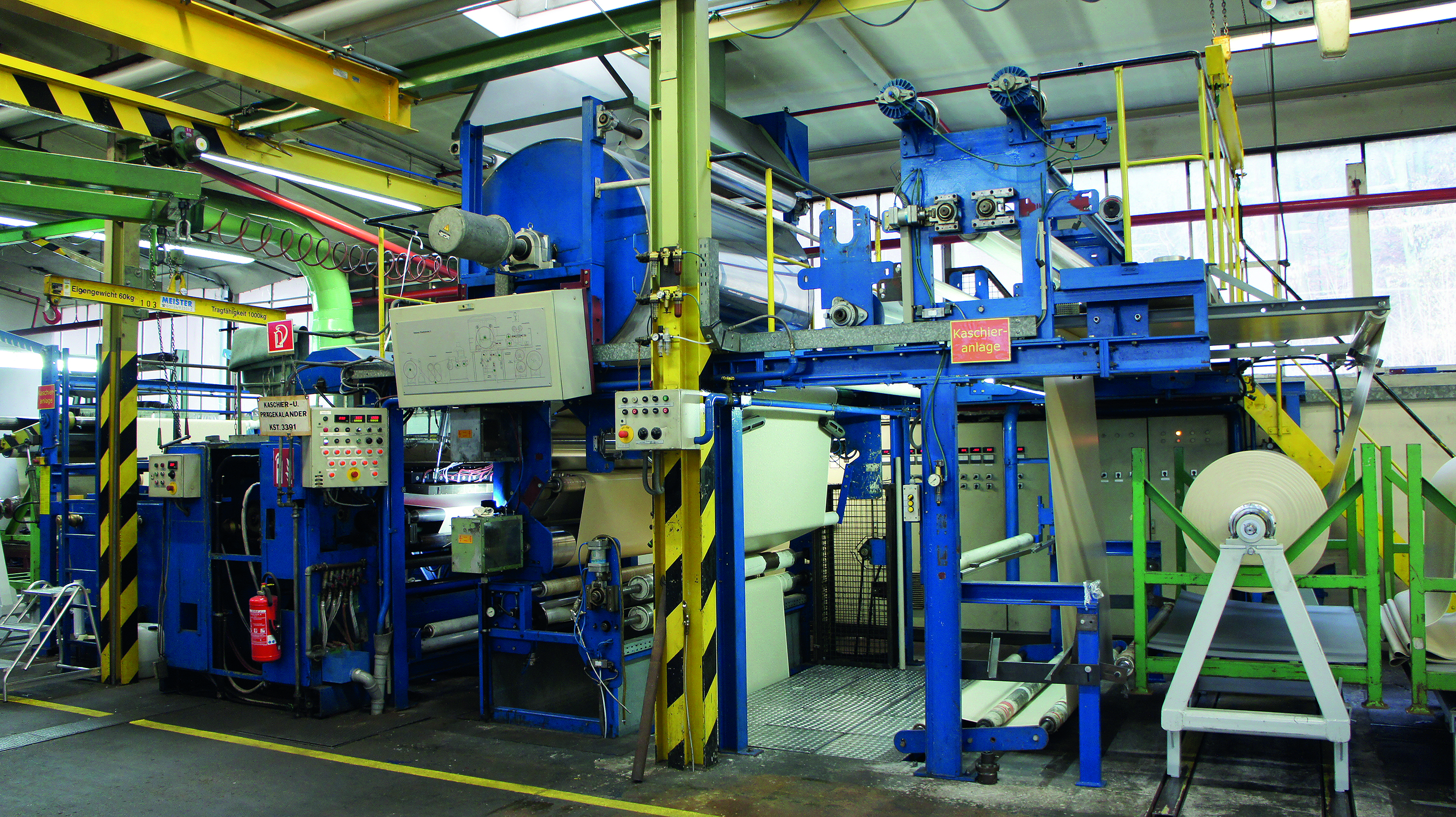

Film extrusion / calendar coating

Application method: Calendaring / Nozzle application

Utilized plastic: Granulate / Dry-Blend with basis of:

PVC • EVA • TPO • TPU • PP • PUR • PE

Coating grammages: 120 g/m2 to 3.000 g/m2

Finished-width spectrum: 800 mm to 2.180 mm

Inline options: Embossing • Trimming • Laminating

Textile coating / Foaming

Application method: Squeegeeing • Padding • Slop padding

(Kiss-Coating) • Rotating stencil application

Utilized plastisol /

Auxiliary textile agent: PVC • PUR • Latex • Acrylate •

Watery dispersions

Coating weight: 50 g/m2 to 4.000 g/m2

Finished width: to 4.600 mm

Inline options: • Embossing up to 2,500 mm finished width

• Gravure and screen printing with 6 plants up to 2,100 mm finished width

• Varnishing up to 2,100 mm finished width

• Trimming

Surface finishing

Printing / Varnishing: Rotatable gravure printing with 6 plants up

to a maximum of 2,000 mm finished width

• Solvent, UV, watery lacquers

Separate embossing and

laminating: • Up to 2,100 mm finished width

• Maximum of 3 layers

• Grit application (application of grit glue / flakes)

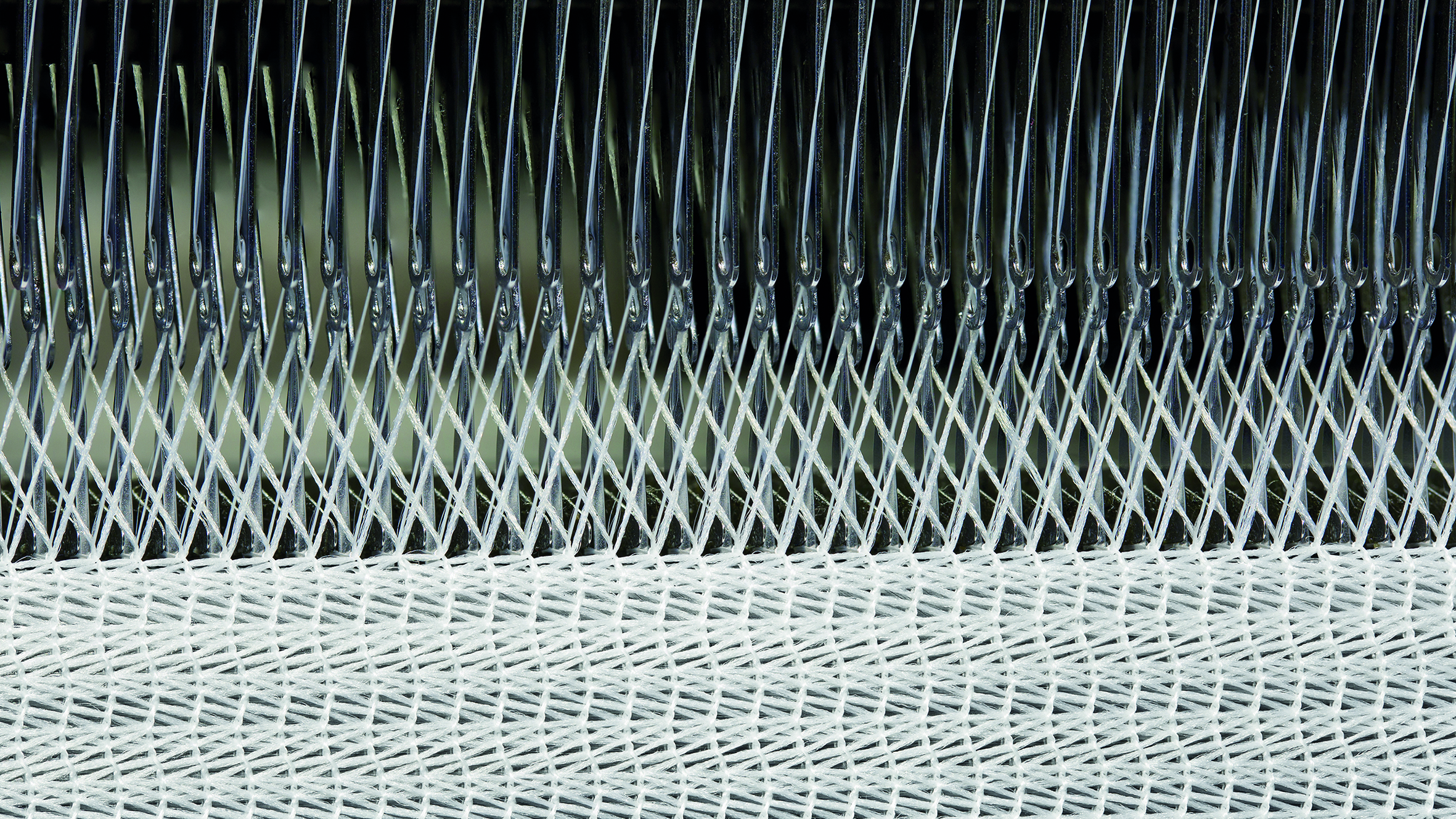

Textile surface production

Machines and technologies: • Hosiery factory with machines of

different performance and technology

(crochet fabric and rustling technology)

• Manufacture of spacer fabrics,

open and closed mesh structures

and coating carrier materials

• Maximum finished width up to 4,800 mm

Competence center development and pilot plants

Pilot plants: • Development and sample production of films, width max. 60 cm and foaming of max. 40 cm in pilot scale

• Film plants including pelletizing extruder

(wide-slit nozzle, rolling mill, granule plant)

• Air-circulating oven for phase-outs and quality control

• Color measurement including formulation, manufacture of color batch

• Weathering, lightfastness, and UV check according to DIN EN ISO*, fire test according to DIN 75 200 and DIN 54 837