SKS (AB Svenskt Konstsilke)

Über uns

SKS was founded in 1918 as a viscose spinner and has developed over the decades towards a dedicated converter for High Performance Yarns.

Today SKS is an international operating company that supplies customers throughout the world with high performance yarns and cords for MRG, Tire and Paper Felt applications. As an important link in the value chain for automotive and industrial manufacturers SKS services these markets by a global sales and marketing approach.

The production plants in Estonia, China and Mexico enable SKS a globally spread market position to serve customers locally with a global approach, ensuring the same high quality of our products worldwide.

SKS’ laboratories and technical service center are constantly improving products and finding solutions through innovation in close cooperation with our customers and partners. In order to have a broad feeding base SKS work closely with Research Institutes and Universities to develop new technical yarns and to modify existing yarn qualities in order to meet new and existing customers demand.

SKS always strives to be at the forefront regarding product development and be open for our customers’ request. It is key for SKS to provide customers with a solution package next to the product, that gives the ultimate price-performance.

Mehr über uns

Unsere Marken

Fabric Forest

We turn fibers into High Performance cords

Keywords

- MRG cords

- Tire cords

- Dipped cords

- Hybrid yarn

- Technical yarns

Unsere Produkte

Single End Cord for Automotive and Industrial Belts

Today, belts in both the automotive and the industrial/agricultural sectors are being required to transmit ever higher forces. More and more aggregates are being driven by single belts, so to extend their lifetimes, belt components need to have high resistance to fatigue. In addition, in the automotive industry, belts are increasingly replacing metal chains as part of the drive to reduce CO2 emissions. SKS offers a range of high-tech cords that allow belt manufacturers to meet these new demands and develop their products accordingly.

Polyester (PET):

- Excellent breaking tenacity with medium elongation and low shrinkage for high flexibility and extended lifetime

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions

- Soft-dipped as well as semi-stiff-dipped for improved fray resistance

Aramid:

- High breaking tenacity with low elongation and creep for excellent power transmission

- High flexibility and dimensional stability, and good chemical and heat resistance

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions.

- Soft-dipped as well as semi-stiff-dipped for improved fray resistance

Polyamide (PA66):

- Excellent breaking tenacity with medium to high elongation for extended flexibility

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions

- Soft-dipped as well as semi-stiff-dipped for improved fray resistance

All RFL-dipped cords have excellent properties of adhesion to commonly used rubber compounds, like EPDM, NR, SBR, CR and (H-)NBR. Cords can also be tailored to optimize adhesion to customerspecific rubber compounds.

Single End Yarn for Paper Felt

Paper Machine Clothing (PMC) calls for stable and uniform monofilamentbased yarn constructions to fulfill the requirements for processing and fabric stability. SKS offers a variety of specially optimized monofilament-based constructions to meet these needs, which fit as well in high demanding paper industry applications like Shoe-Press-Belts.

Monofilament Polyamide (PA6):

- High uniformity in linear density, diameter, surface properties and shrinkage to ensure high stability

- Available as twisted cord and in a wide variety of tailor-made plied Constructions

Hybrids:

- High uniformity in linear density, diameter and shrinkage to ensure high stability with tailored and optimized surface properties

- Available as twisted cord and in a wide variety of tailor-made plied constructions

Twisted monofil

All RFL-dipped yarns have excellent properties of adhesion to commonly used rubber compounds, like EPDM, NR, SBR, and CR. Yarns can also be tailored to optimize adhesion to customer-specific rubber compounds.

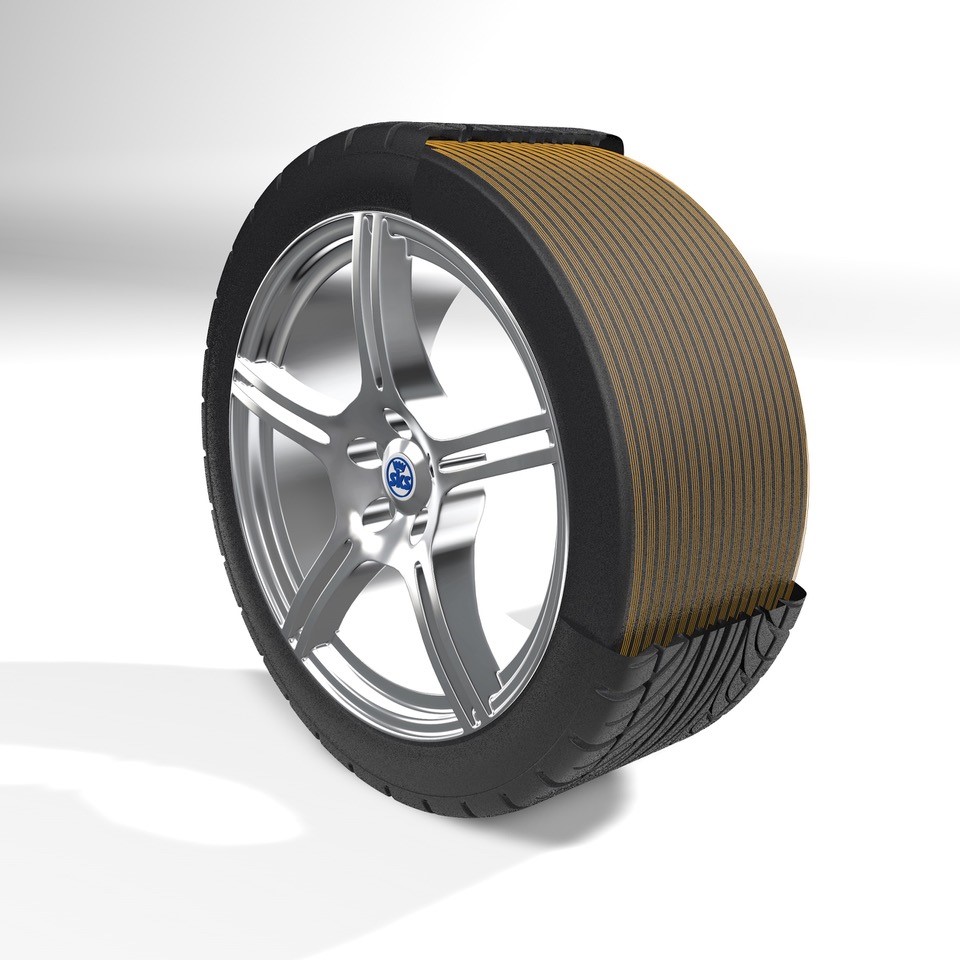

Single End Cord for Tires

High uniformity and clean, perfect processing are the key requirements that today’s

tire manufacturers have of Single End Cord (SEC). The use of SEC in specific production methods is gaining ground due to higher efficiency and flexibility of the

manufacturing process. For many years, SKS has been a key supplier of SEC, offering

a tailored portfolio of high-tech SEC.

Hybrids:

- High breaking tenacity with low elongation and creep for excellent driving stability

- High flexibility, extended lifetime and good chemical and heat resistance

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailor-made plied constructions

- Application: Cap Ply

Polyamide (PA66):

- Excellent breaking tenacity with medium to high elongation, ensuring comfortable driving

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions

- Application: Cap Ply

Rayon:

- Excellent breaking tenacity with low elongation and low shrinkage for high dimensional stability

- Bio-degradable

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions

- Application: Carcass

Polyester (PET):

- Excellent breaking tenacity with medium elongation and low shrinkage

- High flexibility and excellent driving handling

- Available as twisted and RFL-dipped cord for excellent adhesion, in a wide variety of tailormade plied constructions

- Application: Carcass

All RFL-dipped cords have excellent properties of adhesion to commonly used rubber compounds like NR and SBR. Cords can also be tailored to optimize adhesion to customer-specific rubber compounds.

All SECs for tire applications are manufactured with 100% quality control throughout each production step, guaranteeing high uniformity and clean processing.

Single End Yarn for Automotive and Industrial Hoses

The challenge for today’s hose manufacturers is to meet the ever-increasing demands of industry and OEMs for higher working pressures, more flexible handling, excellent dynamic performance, greater durability, and safer, “greener” products. SKS meets these diverse demands with a wide range of high-tech yarns for hose reinforcement.

Aramid:

- High breaking tenacity with low elongation and creep to ensure high working pressure

- High flexibility and dimensional stability,and good chemical and heat resistance

- Linear density range from 420–3360 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyvinylalcohol (PVA):

- High breaking tenacity with low elongation and low shrinkage for high dimensional stability

- Bio-degradable

- Linear density range from 1330–2000 dtex (including plied constructions)/li>

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Rayon:

- Excellent breaking tenacity with low elongation and low shrinkage for high dimensional stability

- Bio-degradable

- Linear density range from 1260–2440 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyester (PET):

- Excellent breaking tenacity with medium elongation and low shrinkage

- High flexibility and handling

- Linear density range from 550–2200 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

Polyamide (PA66):

- Excellent breaking tenacity with medium to high elongation for extended flexibility

- Linear density range from 470–2100 dtex (including plied constructions)

- Available as twisted greige yarn or RFL-dipped yarn for excellent adhesion

All RFL-dipped yarns have excellent properties of adhesion to commonly used rubber compounds, like EPDM, NR, SBR, and CR. Yarns can also be tailored to optimize adhesion to customer-specific rubber compounds.