adphos Digital Printing GmbH

Adresse

adphos Digital Printing GmbH

Bruckmühler Str. 27

83052 Bruckmühl

Germany

Telefon+49 8061 3950

Fax+49 8061 395395

Entdecken Sie mehr von uns

Folgen Sie uns auf

Über uns

aNIR® and aLITE® are company developed and widely patented platform technologies of the adphos group from Bruckmühl, which has been used successfully in various industrial sectors for heating, drying, sintering and curing applications for now more 30 years.

One area of the aNIR® platform technology is the aLITE® technology designed and specially developed for thermal surface processes. The aLITE® technology enables in seconds the drying and fixation of coatings, dyeing and printing processes on textile materials.

Above all, the absolutely distortion-free drying of water-based printing inks, inks and pigment or dispersion paint systems, which is possible especially at low temperatures. Now enabled at greatly increased production speeds (due to the extremely small space requirement), improved product quality (due to low thermal stress during the process) and enormous cost advantages (due to extremely reduced energy requirements). All delivered with an unprecedented low level of environmental pollution (due to CO2-emission-free and environmentally friendly process control).

The innovative aNIR®/aLITE® technologies have now also proven themselves several times in different applications in the textile sector.

There are proven advantages especially with conductivity-maximized aNIR- drying and sintering processes in a matter of seconds and this with temperature-sensitive substrates. Even multilayer coating drying solutions, e.g. for complex printed electronic (technical) textiles, enable the use of aNIR®/aLITE®.

Space-saving and production-enhanced printing/coating processes, whether coupled with screen printing, slot-die, spray or inkjet, can now be realized with the adphos electrothermal and thus CO2-emission-free drying solutions. Even water-based thick-film applications, such as for impregnating and coloring or gluing or other functional layers for temperature-sensitive materials (even below ≾ 80 °C), can now also substitute usual/required UV processes with aNIR®/aLITE® solutions.

Application-optimized and customer-specific drying and sintering solutions, whether as a booster, replacement or greenfield solution, are implemented for a wide variety of textile surface treatments as discontinuous or continuous R2R or as integration into complex textile production plants.

Unsere Produktgruppen

- Technology and Processes

- Coated Textiles

- Bondtec (Surface & Bonding Techniques)

Unsere Anwendungsbereiche / Lösungen

Keywords

- Fixieren

- gedruckte Elektronik

- Batterien

- Smart Textiles

- Trocknen

Unsere Produkte

Smart Textiles/Multilayer Printed Electronic

The aNIR® and aLITE® platform technologies enable a variety of new manufacturing processes especially for smart textiles and other multilayer textile-based printed electronics.

aNIR® and especially aLITE® allow coatings to dry completely without distortion, especially at low temperatures, even with aqueous thick-film wet layers. Not only the drying times can be reduced by orders of magnitude compared to conventional hot air drying systems (typically from minutes to a few seconds). In addition, significantly increased production speeds are realized due to the small space requirement, often added, multilayer application and drying processes are then also possible in one line. Further enormous cost advantages result from the greatly reduced energy requirement of the adphos electrothermal drying solutions (approx. only 10% - 30% of hot air, or ≤ 30% of (N)IR-based dryers), which are intrinsically also completely zero CO2-emission due to their working principles.

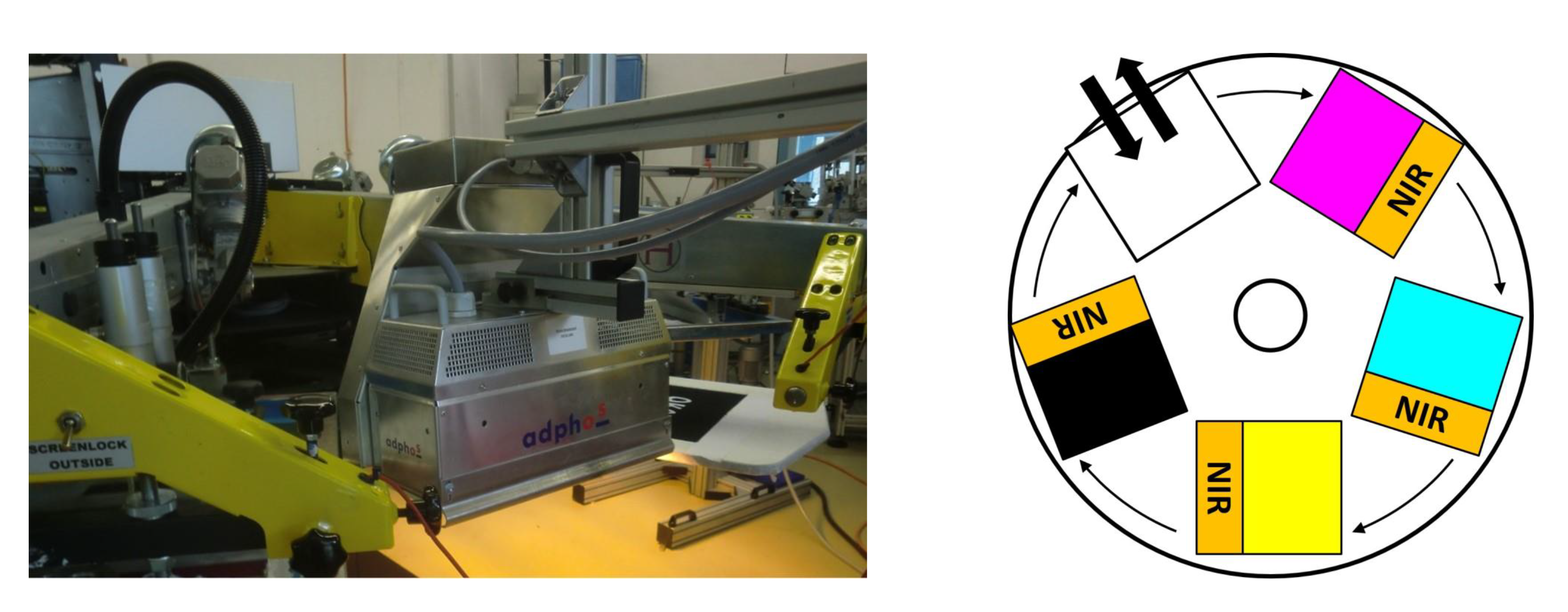

Carousel Screen Print

Compact aNIR® drying solutions for the integration of multi-print carousel screen printing systems can be offered application-optimized and customer-specific also in existing lines.

This can greatly increase productivity by converting the IR drying stations required today into additional screen-printing positions. The aNIR® drying modules are mounted directly on the screen-printing frame and are only activated during the carousel feed.

This also avoids the unavoidable high thermal loads (due to heat radiation from the textile product carriers heating up) on the screens, as well as the on/off cycles of the aNIR® drying systems required to be < 1 second, saving many times over in energy consumption. High two-digit cost advantages result essentially from the possible increase in productivity, reduction in energy consumption and the considerably longer operating times before the cleaning/maintenance of the screens is required.

Dye/Spray Coating - TeDyLITE®

The adphos proprietary TeDyLITE® (Textile Dyeing Light Initiated Thermal Emission) process was developed especially for textile dyeing and impregnation processes, for Foullert or spray-coating based coatings. With this, water-based pigment and dispersion paint systems can be dried and fixed in a matter of seconds, which with today's conventional hot-air systems require thermal fixation processes of up to several minutes. For certain commercially available dyeing systems, this can even be achieved in a single-stage drying/fixation process.

In addition to the possible extreme reduction in space for the required process steps, the TeDyLITE® process leads to significantly reduced energy consumption and enables a greatly simplified textile web treatment. Due to the working principle of the electrothermal TeDyLITE® solutions, they are also completely free of CO2-emissions.

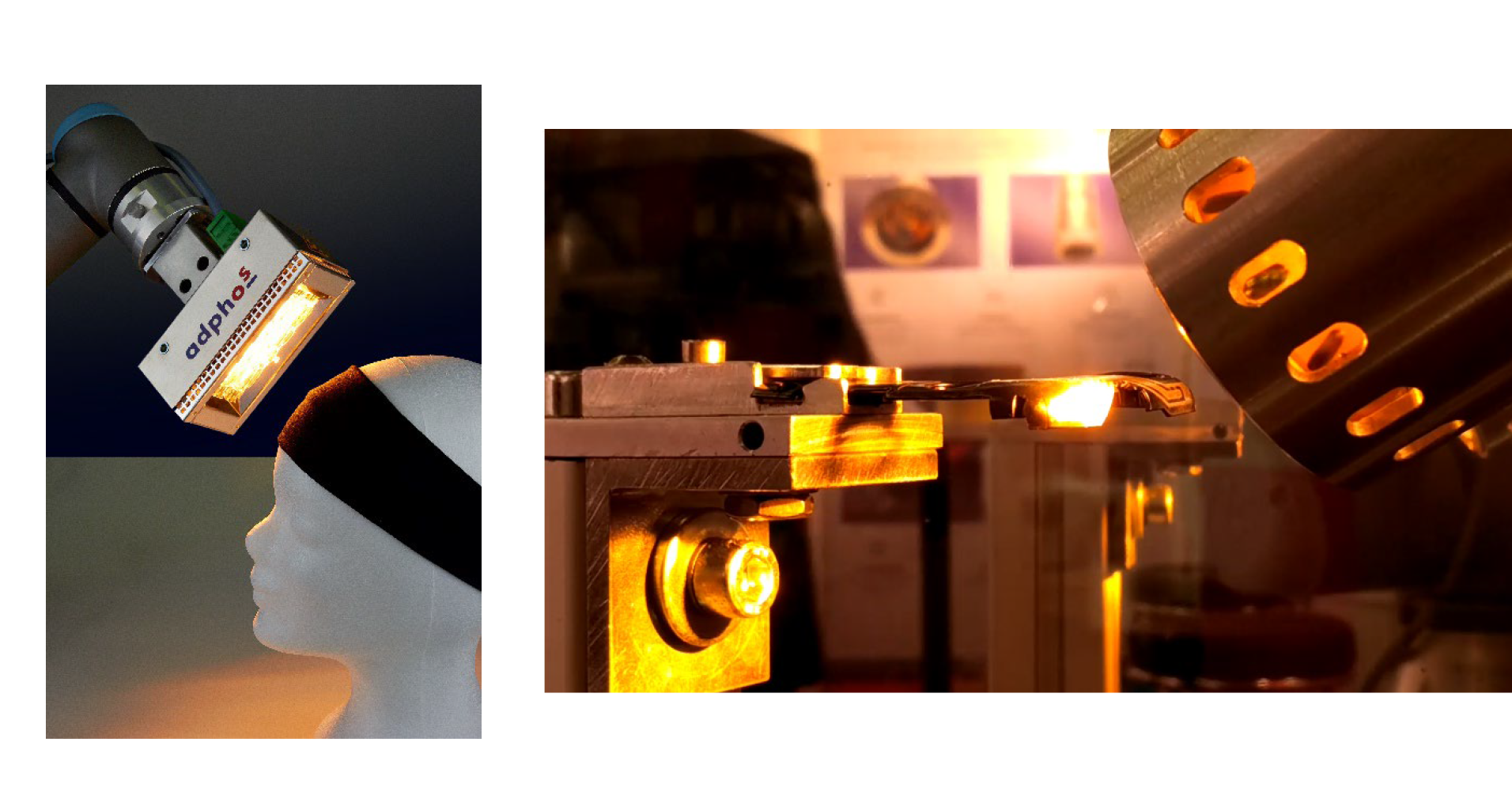

Direct to Shape 3D-Print

The possible aNIR® drying in seconds now also allows a simple adaptation to printing and coating systems for 3D-components and 3D-continuous applications. In this way, aNIR® enables dynamic, 3-dimensional spontaneous drying focused directly on locally limited, coated textile structure.

Due to the functional principle of the aNIR®-technology, it can be used for extremely temperature-sensitive textiles (≥ 60 °C). The compact, weight-minimized aNIR® drying module designs also allow assembly with highly dynamic (several G-acceleration) robot-supported process systems.

Inkjet Printing on Textiles

Compact, spontaneous, dynamically defined and controlled drying solutions for multipass and single-pass IJ printing systems are offered application-optimized and customer-specific.

The highest productivity increases, possible on the market, can be achieved by minimizing space and weight, with the lowest thermal loads on the printheads carrier respectively the conveyor belt and the adjacent system components.

The low possible temperatures of the printed textiles, due to the special aNIR® functional principle for drying especially water-based inks allow high-performance and high-quality IJ printing solutions on very temperature-sensitive textiles.

The possible ultra-fast aNIR® drying also makes high-performance R2R-IJ printing processes possible today. Even at printing speeds of 150 m/min, a max. aNIR® drying length of < 1.5 m is required, compared to the otherwise usual 5 - 6 m for IR or > 15 m for hot air drying solutions.

Unsere Ansprechpersonen

Kai Bär

General management

Managing Director

Volker Nitsche

Project Management

Employee