A. MonfortsTextilmaschinen GmbH & Co. KG

Adresse

A. MonfortsTextilmaschinen GmbH & Co. KG

Blumenberger Str. 143-145

41061 Mönchengladbach

Germany

Telefon+49 2161 4010

Entdecken Sie mehr von uns

Über uns

For 140 years the Monforts commitment to customers is to be helpful – accurate – fast - reliable and has shaped the image as a leading global supplier of textile machines and systems for the finishing and coating of woven and knitted goods as well as special applications.

Successful textile manufacturers worldwide have been relying on systems from A. Monforts Textilmaschinen GmbH & Co. KG for decades. They offer their own customers real and globally recognized premium quality and thus conserve important resources - their own and those of the environment.

With systems from Monforts, the two most important economic principles “efficiency” and “effectiveness” come together naturally and create the basis for sustainable economic success as well as high quality, innovation and satisfaction along the entire textile value chain.

Special needs call for special solutions. Monforts has the know-how and technologies necessary to build special ranges to precisely meet your expectations.

Our Product Range

- Universal dryers

- TwinTherm dryers

- Belt dryers

- High temperature stenters

- Large widths stenters

- Explosion-proof execution

- Thermobonding ranges

- Coating lines

- Special lines according to customer need

Suitable for

- Glas fibre fabrics

- Light protection

- Tarpaulins

- Billboards

- Floor coverings

- Nonwovens

- Spacers

- Membranes

- Medical care

- and many more…

Unsere Produktgruppen

- Technology and Processes

Unsere Anwendungsbereiche / Lösungen

Mehr über uns

Special Interests

Downloads

Dokumente

Keywords

- Stenter | Spannrahmen

- Spezialanlagen | Special Lines

- Coating Lines | Beschichtungsanlagen

- Sustainability | Nachhaltigkeit

- Textile Finishing | Textilveredlung

Unsere Produkte

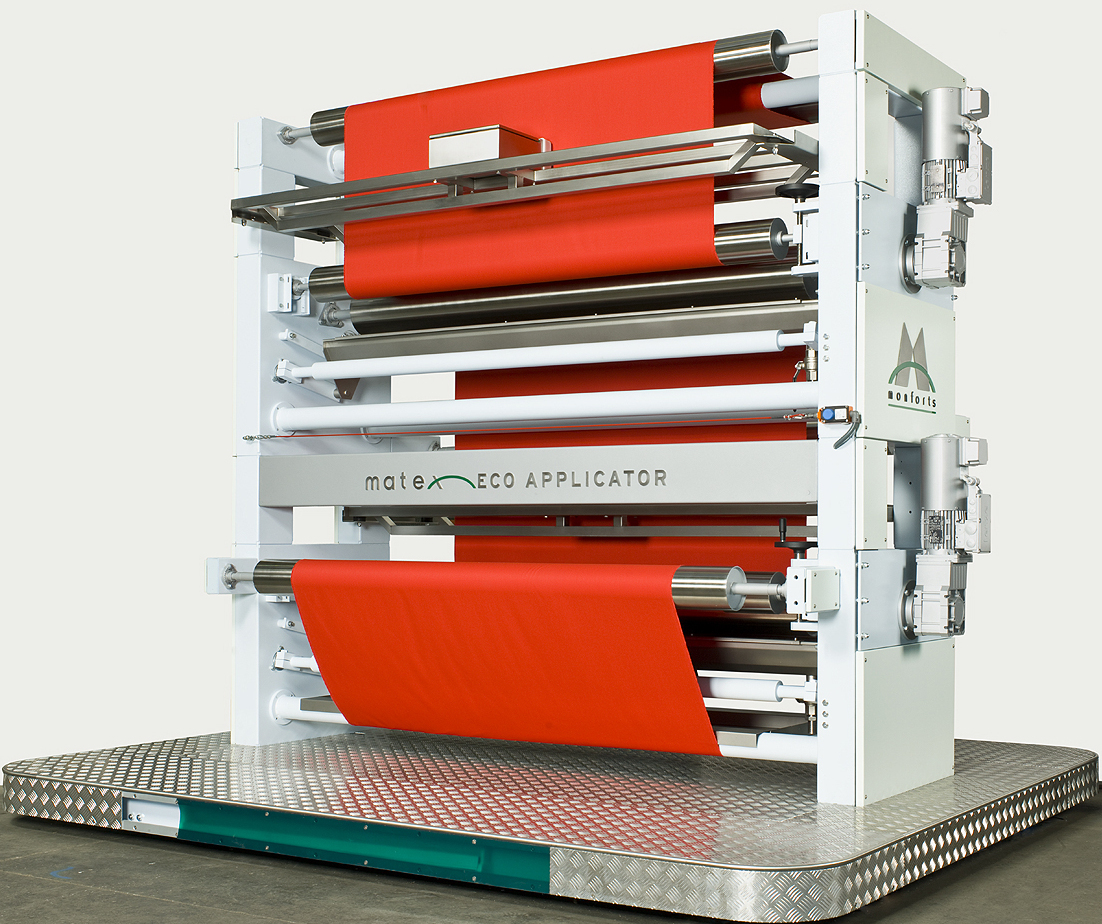

Matex EcoApplicator

Minimum liquor application device with powered liquor rollers. The alternative to padding. Reduced liquor content for lower remaining liquor in the trough. Universal application: Liquor application to one or two sides or different liquor application on front and reverse side.

Your Benefits:

- Save energy thanks to less residual moisture after liquor application.

- 35% less liquor pick-up than with padder

- 35% less drying energy

Applications:

- Finishing of workwear

- Over dyeing or finishing of denim fabrics

- Hydrophobing/hydrophiling professional clothing

Thermex

Thermex is the modern system for continuous dyeing and finishing. It is characterised by exceptional cost-effectiveness when dyeing both large and small batches.

The latest future-oriented technology and process engineering ensure that it can be expanded into a large continuous dyeing range. All-in-all, a universal hotflue for continuous dyeing, condensing and thermosoling with high reliability even at maximum fabric speeds. Exclusively for Econtrol® processes for the continuous dyeing.

Your Benefits:

- More than 45% less energy

- More than 60% less water

- More than 80% less chemicals

- Low investment costs

- Low personnel requirements

- Good fabric fastnesses

- Very low costs

Econtrol® is a registered mark of DyStar® Colours Distribution GmbH, Germany.

Montex®Coat

The coating sector is a steadily growing segment in the field of textile finishing. As a leading manufacturer of textile finishing machines, Monforts is responding to this development with new and innovative solutions, in particular also in the field of technical textiles.

Monforts offers textile finishers tailored technologies for saving energy and adding value to their products using suitable coating ranges.

To meet the individual requirements a wide range of different coating systems is available – also in combination. The various coating modules can be employed for foam and paste coating.

- Air knife coating

- Roller knife coating

- Screen printing

- Magnetic roller coating, direct and indirect

- Optimized control device for easy use and handle

- Automatically working side limiters for reliable sealing even for air knife coating

In addition, Monforts offers the necessary technology for solvent-based coatings with EX-proof ranges and for high-temperature processes up to 320°C, such as for PTFE sintering.

coaTTex

The new versatile coaTTex coating unit exclusively dedicated to air knife and knife-over-roller coating is suitable for single-sided application with paste or foam, for both incorporation into existing finishing ranges as well as installation with new Monforts lines, notably the industry-leading Montex stenter systems.

A wide range of coatings can be applied to fabrics for providing functions such as waterproofing, liquid and gas protection and breathability, in addition to foam lamination and coating, including black-out coating.

The considerable technical textile end-use applications envisaged for the coaTTex range from window blinds to abrasive cloths and from airbags to sails.

With an operational speed of up to 40 metres per minute, coaTTex units are available in nominal widths of between 1800mm to 3600mm and their robust construction is characterised by a rotating beam for the fixation of up to three different knife executions.

Central adjustment of both the horizontal and vertical position of the beam, and also of the knife angle, enables easy adaptation to new projects and automatic tension control guarantees hight quality production. In addition, the cleaning blade for the coating roller is pneumatically controlled, as is the lifting of the beam at seams and clamping during fabric standstill.

The coaTTex is Monforts response to a demand from the market for a reliable coater that can be up and running very quickly, is easy to operate, and enables a wide range of performance properties to be imparted on fabrics extremely economically.

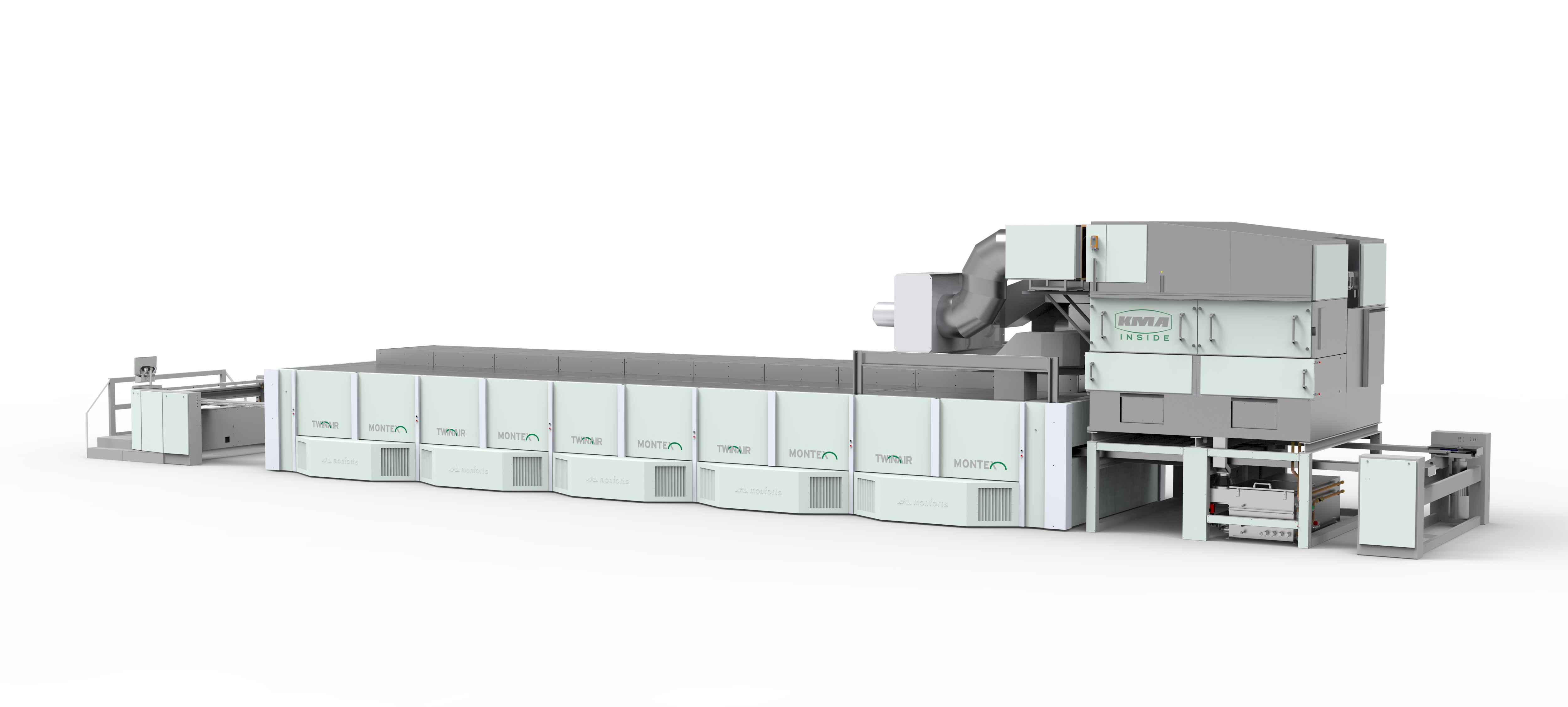

Montex

The Montex stenter offers the latest technology for the optimum customer benefits. The sophisticated chamber design, the individually controlled air guidance system with maximum temperature precision and temperature distribution or the excellent energy management are just a few factors. New features now make the Montex an even more universal solution and even easier to operate.

Your Benefits:

- Optimum accessibility

- Space saving construction

- Integrated exhaust air ducts

- Special panelling for low heat radiation

- Careful sealing of all connecting positions and chamber accesses

- Motors are accessible from outside the chamber and can be replaced without the use of hoists or cranes

- The use of standard components provides benefits in maintenance and inventory for the user

Always be on the safe side with the modularly expandable Monforts MonforClean system. To meet the growing demands in heat recovery, exhaust air cleaning and elimination of odours Monforts offers you

- air/air or air/water cross-flow heat exchangers

- electric filters with fully automatic cleaning

- UV light module to eliminate undesirable odours

Your Benefit:

- The CO2 emissions from the range are further reduced and you can make a valuable contribution to environmental protection.

The revised and further optimised Qualitex visualisation software offers the operator even more reliability and benefits:

- Higher ease of operation with full HD monitor and slider function

- Dashboard function with individual adaptation to the operating

- states and faster access to the comprehensive recipe data management

- all based on the latest future-proof software