HEMP-ACT

Technology transfer

Zum Produkt

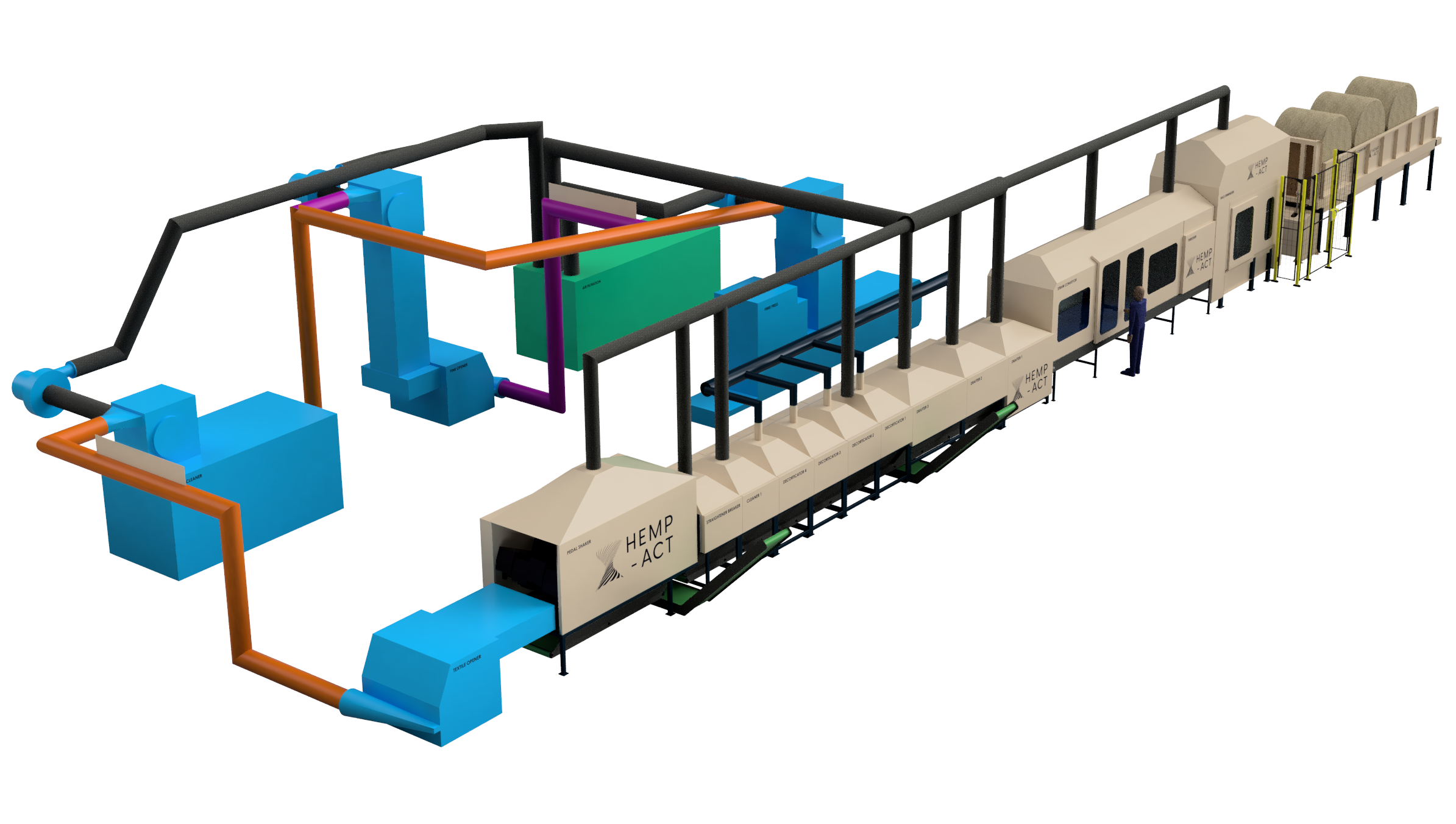

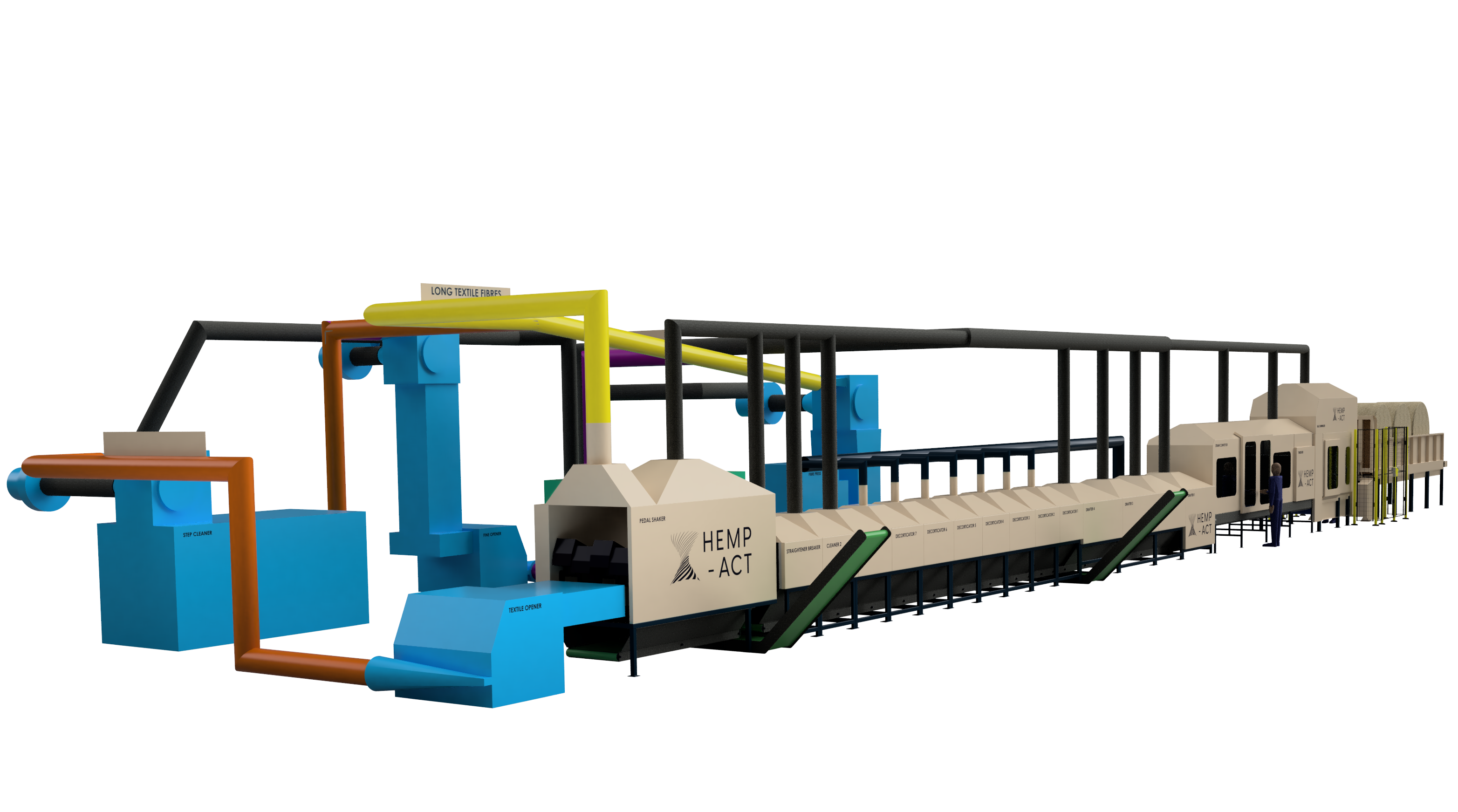

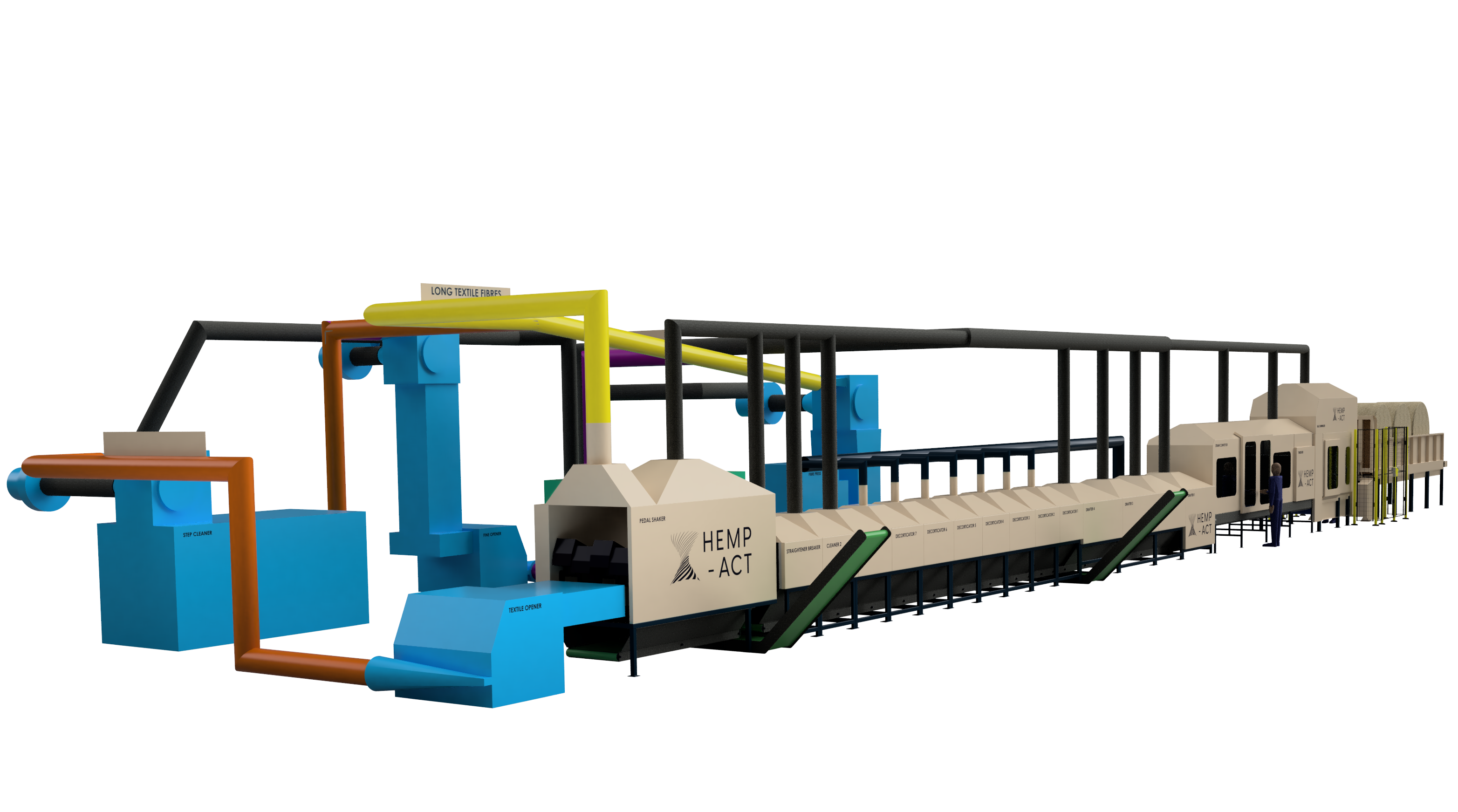

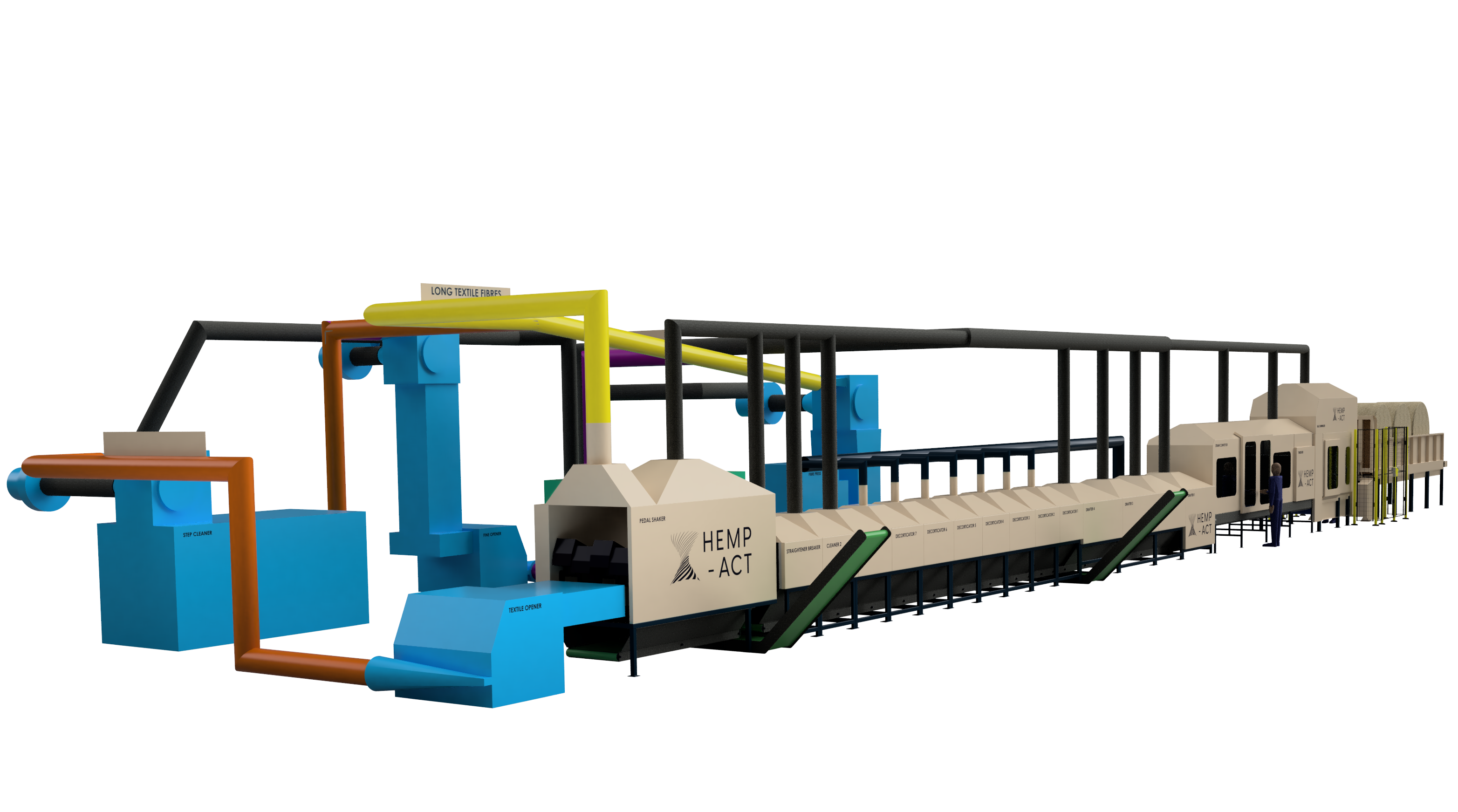

Hemp Textile Decorticating Line

Zum Produkt

Technology transfer

Zum Produkt

Hemp Textile Decorticating Line

Zum Produkt

Technology transfer

Zum Produkt

Hemp Textile Decorticating Line

Zum ProduktÜber uns

From a bale of hemp straw to a hackeld sliver of long fibers

HEMP-ACT is commited to offer you breakthrough solutions to extract and market profitable long textile hemp fibres...But not only !

At the end of 2023, we confirmed the technical and economic performance of our tools at the ADD-ITC conference. These encouraging results are directly linked to the process shortcuts that we implemented.

During the months of December and January, we continued a series of tests to finalize our line design in search of the best service provided to our customers. Our process and our tools have been designed so that our customers can:

extract high added value from their textile fibers

be equipped with the capacity to transform and add value to all the qualities of straw that their supplying farmers could deliver to them.

market textile fibers and reinforcement of profitable bio-composites while being ultra competitive, a sine qua non condition for their massive industrial appropriation

We are thus finalizing our unique 2in1 decorticating and combing/hackling solution by integrating into our next decorticating line HD1300TEXTILE_00:

finer cleaning of the fibers to eliminate the last hemp,

hackling/combing the fibers to improve their parallelization and to refine the fiber bundles

packaging of the long and textile fibres in a sliver packaged in a roll , or in bulk in textile bales.

These last equipements, thought out for a long time, will integrate the new version of our specifications “Manufacturing HD1300 TEXTILE_00”. Our next decorticating line will thus produce long fibers in sliver or in bulk, and if necessary short and technical fibers, with little additional equipment. Our customers will thus get the best value from all their materials on their targeted markets.

Beyond hemp, a multiple range of bioresources in search of solutions

The experimental work carried out in recent weeks, where we tested new tools, also revealed the adaptation of our solutions to multiple plant raw materials which are looking for textile or material valorizations throughout the world.

The tools we tested confirmed:

their potential for extracting bast fibers,

but also their ability to process plants with low fiber content, shredding them and thus opening up the possibility of up-grading them into materials via non-woven processes.

The deposits of these materials, spread across the world, are gigantic and there is an urgent need to valorize them in order to boost local economies and to adapt to the effects of climate change, as well as to reduce its effects.

The origin of these bioresources that will have to be treated is diverse and comes from 3 major groups:

Co-products from harvests : oilseed flax, rice, palm tree, pineapple, abaca, etc.

invasive plants: water hyacinth, typha, etc.

Plants from marginal, uncultivated land: broom, nettle, etc.

We listen to your needs and your projects to move forward together in the valorization of your specific bioresources. Contact us !

BACK TO THE BASICS

At the start of the 21st century, humanity is facing multiple crises, on a scale never known before. Almost all of these crises come from an increase in the rate of CO2 in the atmosphere and a release of pollutants that planet Earth can no longer support..

The fashion industry is said to be the second most polluting industry in the world. As much as the attractiveness of big brands is almost magical, it is the responsibility of these brands and of the fashion industry to renew themselves and to take very seriously into account the environmental, social and North/South equity issues.

After decades of banishment, hemp returns to the front of the stage thanks to these multiple assets:

hemp grows in almost all latitudes

growing hemp consumes three times less water than corn or cotton

Hemp growing regenerates the soil

hemp is grown without pesticides and it smothers weeds

hemp feeds us with its seeds, dresses us with its fibers from the bark and lodges us with hemp shivs (from its wood)

hemp co-products are sequestering 15ton eqCO2/ha/year

Hemp today represents only 0.02% of textile fibers, we 'll make it a mainstream textile fibre by 2050, representing 10% of th total amount of processed textile fibres, to be grown on more than one hundred Million of hectares over the world

HEMP-ACT : the solution to make hemp a mainstream fibre in a renewed fashion industry.

HEMP-ACT has developed a new process for the transformation of hemp straw with the aim of increasing the use of hemp around the world. Our goal: to have hemp reach at 20 % share of the global textile market by 2050. 100 millions of hectares for 30 millions tons of fabrics.

YES! HEMP IS BECOMING THE STAR of textile fibers for decades to come within a fashion industry that is reinventing and transforming itself to both adapt to climate change and to reduce its environmental impacts.

Hemp is a fiber that supports an economy of ecosystem regeneration and whose production in a multitude of local sectors will promote the autonomy and resilience of these territories while remaining connected to the global economy.

Hemp is a pleasant material to wear, very resistant, breathable which brings real comfort both in warm periods, and in cold climates. It is a fiber of character that gives each fabric a unique touch, feeling and texture.

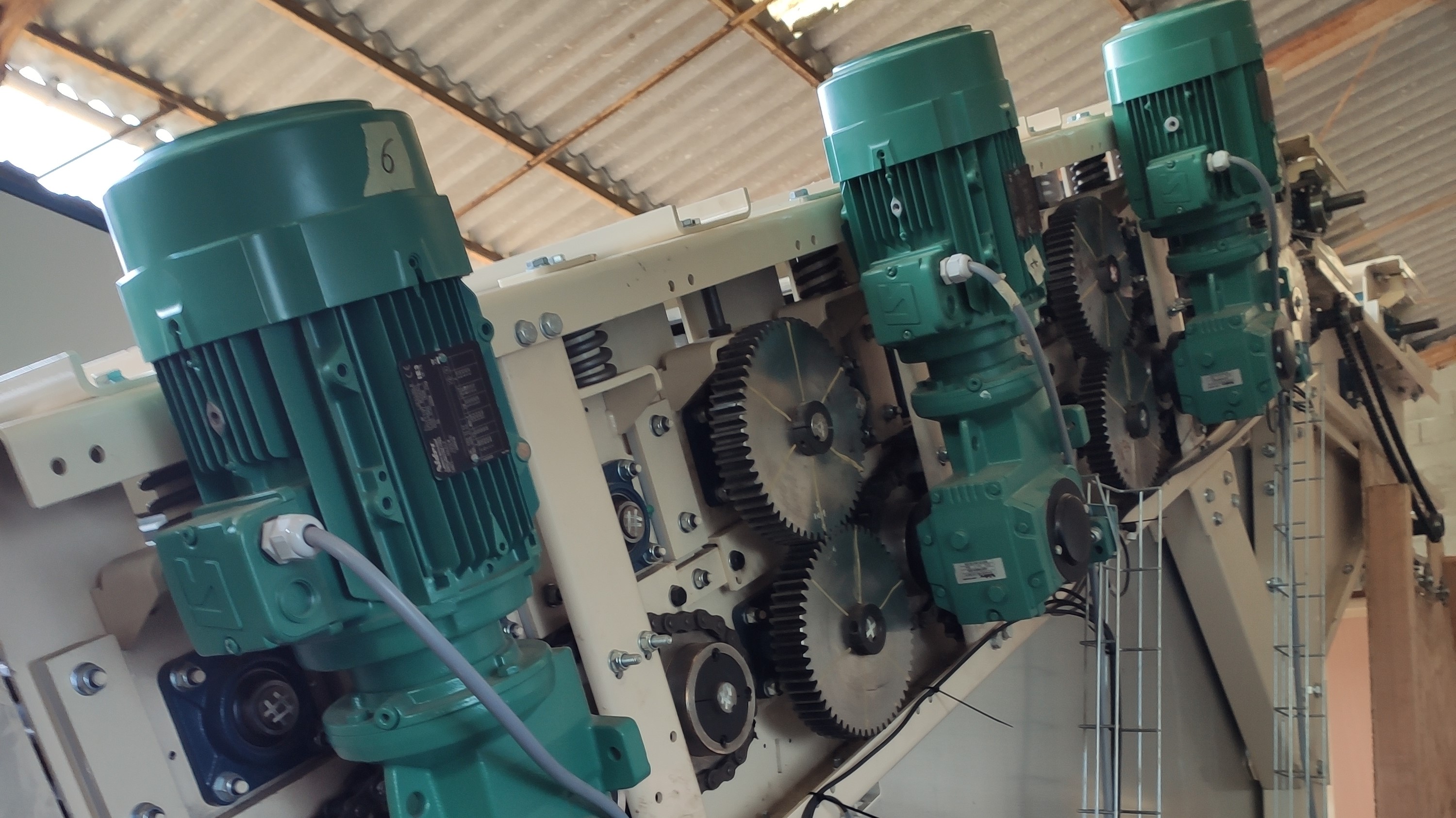

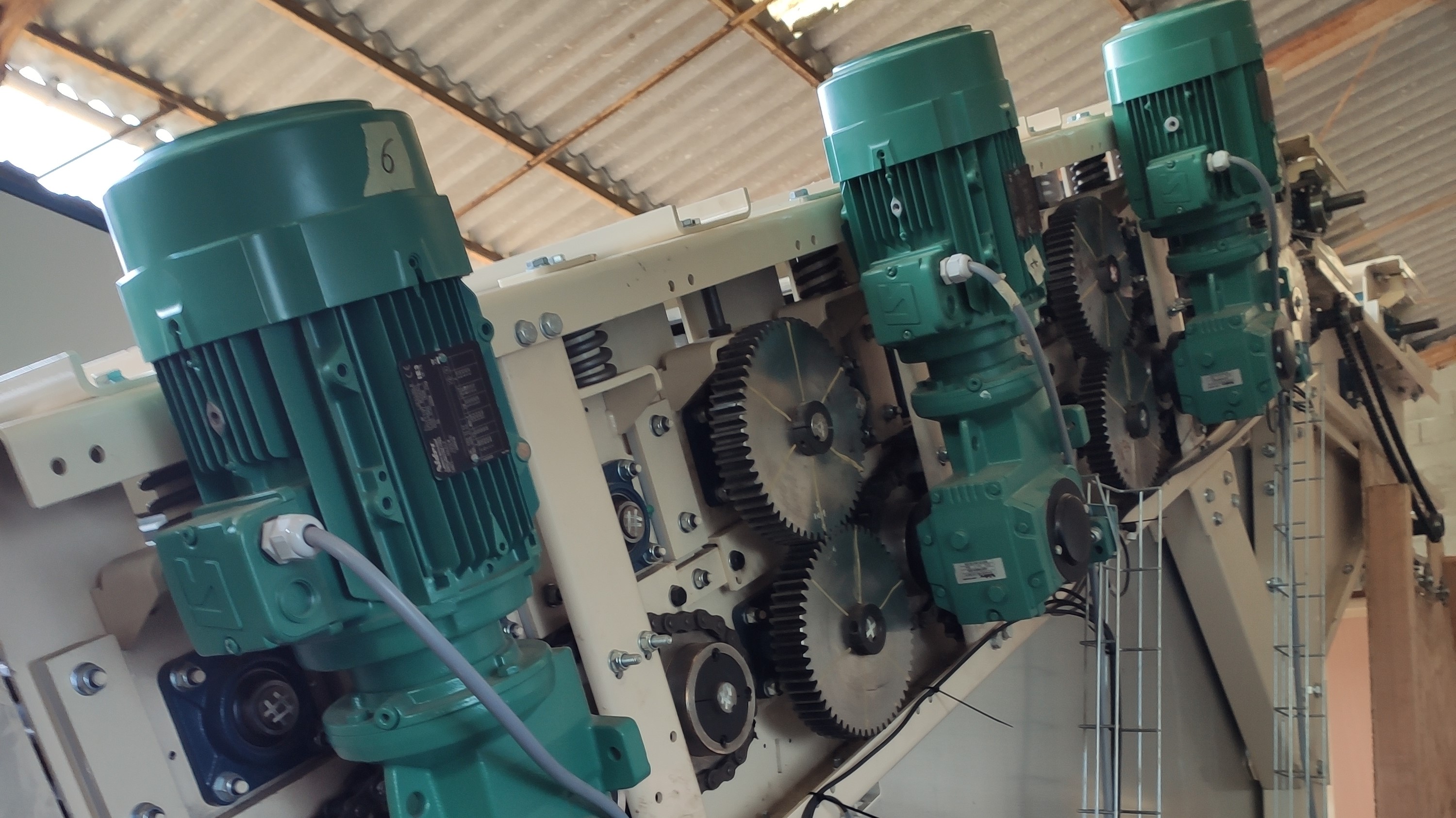

HEMP-ACT has developed a cutting-edge decorticating line which allows the extraction of long hemp textile fibers which can thus be used in all the spinning mills in the world: wet or dry spinning such as linen spinning, worsted spinning, or ring spinning or open end spinning.

We have designed a simple, effective, easy to use and energy efficient process. We gave it a measured dimension to keep it affordable so that it will be massively and very quickly adopted by tens, then hundreds and thousands of local industries around the world.

Machines without the know-how would be nothing, so we provide you, our customers, with all the training and support dedicated to make your project profitable, and we are offering you decortication as a service for your FR&D needs and to initiate your markets.

We are open to enter new partners and investors

Finally, in preparation for marketing our mass-produced lines, we are strengthening our company and will be carrying out a capital increase in the next few months. If you would like to take part in this fund-raising, or better still, become a key partner in a company that is set for tremendous growth, now is the moment to invest in HEMP-ACT.

Unsere Produktgruppen

- Technology and Processes

- Fibres and Yarns

Unsere Anwendungsbereiche / Lösungen

Mehr über uns

Special Interests

Downloads

Keywords

- Hemp Yarns

- HEMP

- Biobased reinforcement

- Natural Fibres

- Biocomposites

Unsere Produkte

Technology transfer

Even if we already work on customer approaches in partnership with other manufacturers, this technology transfer offer is particularly aimed at them in a new sense where we could:

- Deliver quasi-machines for their commercial project

- Or sell licenses on an identified part of our offer,

- Or even think about other forms of partnership, transfer of our designs and our skills

Decorticating Service

Our services to accelerate your development

We have reserved privileged access to our prototype line to continue carrying out your materials R&D work or for your company's business start-up needs.

Concerning our offer of decortication and pre-carding of your straws and fibers, for your batches of materials from 100 kg to 10 tonnes, 3 slots are still available, between June and September, reserve them as soon as possible.

Decorticating line for technical fibers

With our HD1300TEXTILE_00 defibration line,

- we have developed a 100% modular solution,

- we have also tested many very different materials to transform them into semi-products intended for numerous markets, mainly textiles and nonwovens.

This leads us to design with you and for you the technical fiber decorticating line 100%adapted to your request, whether you wish to address the markets:

- cotton fibers of hemp, linen or other bast fibers

- valorization of agricultural co-products, more or less fibrous for the nonwovens industry

- valorization of invasive plants for the nonwovens industry

- valorization of plants from marginal lands for the nonwovens industry

and for all your other projects

We remain attentive to your specifications, and if feasible, we will find together the solution 100% adapted to your needs for a defibration line for technical fibers. Your HD1300 TEKFIBER line.

Dowload the syntetical technical datasheet on our Techtextil webpage.

Project support, skills transfer and tailor-made training

Always at your disposal: our training offer, transfer of knowledge and skills, cultivation support and monitoring of your hemp project to facilitate, accelerate and secure the emergence of your hemp production business and its first transformation.

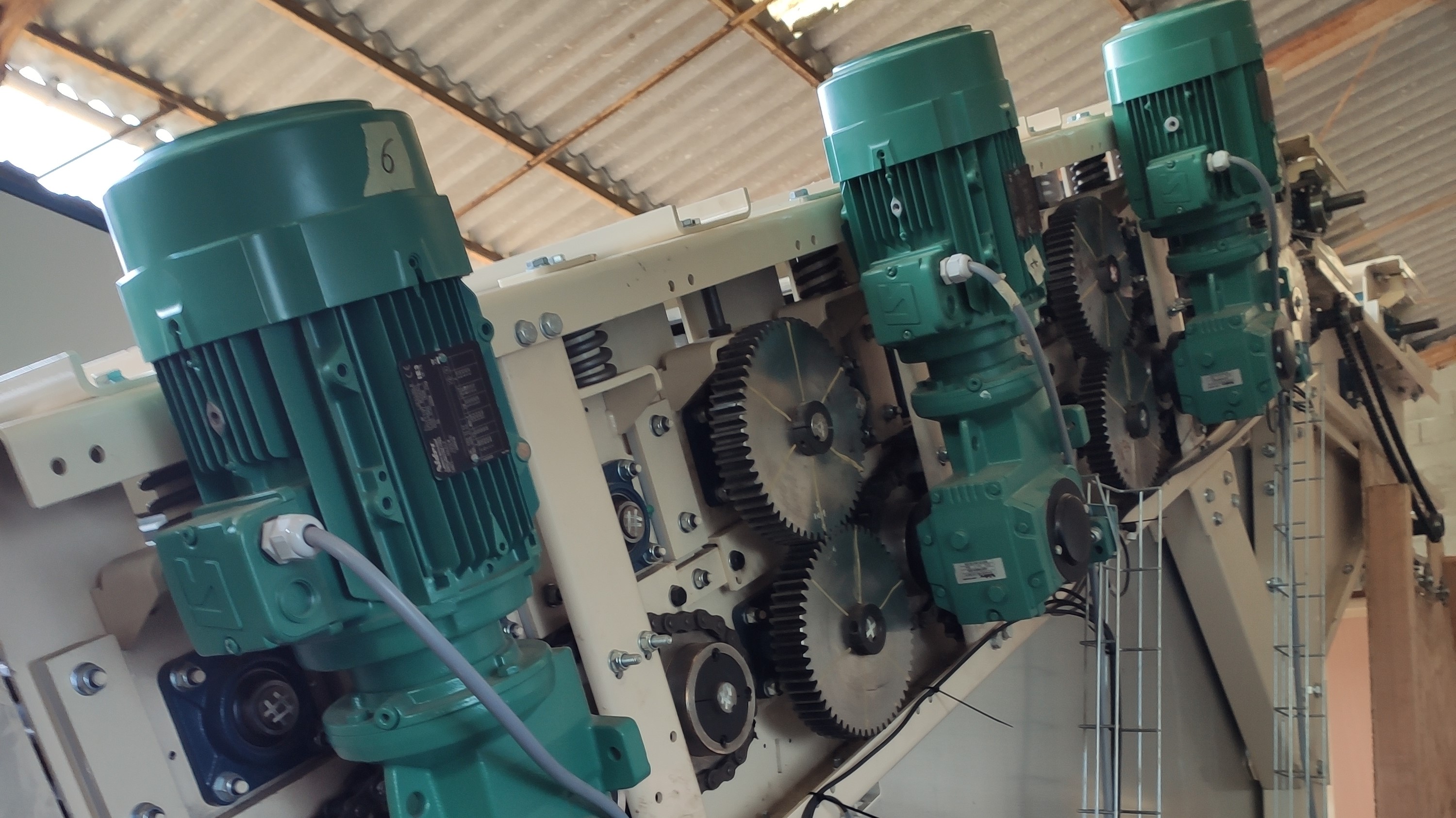

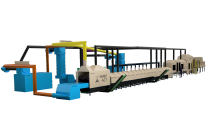

Hemp Textile Decorticating Line

On the road to selling our mass-produced decorticating lines, we move on to the second stage: a pre-production decorticating line, the HD1300TEXTILE_model00.

Its design is based on our pilot line and on the experience produced in transformation as well as on parallel tests carried out with manufacturers and laboratories partners.

In connection with our latest tests and with a demand which is confirmed for the production of a sliver of long hemp and textile fibers, we have evolved the line design to integrate from the 00 model the equipment which will allow us to produce on a single line a sliver of long textile hackled fibers, from a round bale of hemp straw. De-fi-ni-te-ly Revolutionary!

We rely on the construction of our pre-series line on the excellence of the operators, design offices and manufacturers in our network: Mecanic Vallée and on the expertise of our fellow French textile machine manufacturers, gathered at the UCMTF.

This new stage will take place over a period of 24 months, after which we will be able to draw up a commercial offer for our series decorticating lines.

Our aim is to commission and test this pre-production line with a partner customer, who will then be able to take advantage of a unique and exclusive acquisition and support offer, giving him a head start over the competition.

Feel free to download the technical datasheet, available on our Techtextil web page.